Water sealing moving integrated type ventilation dust removing cover

A one-piece, ventilation hood technology, applied in the direction of dust removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of poor dust removal effect, poor sealing, not high temperature resistance, etc., to achieve small air leakage and easy maintenance , good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

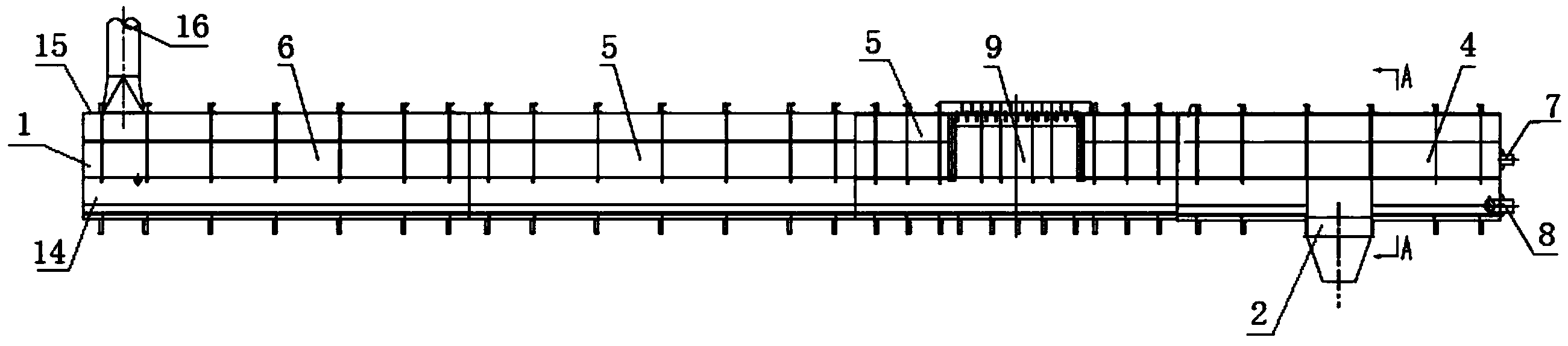

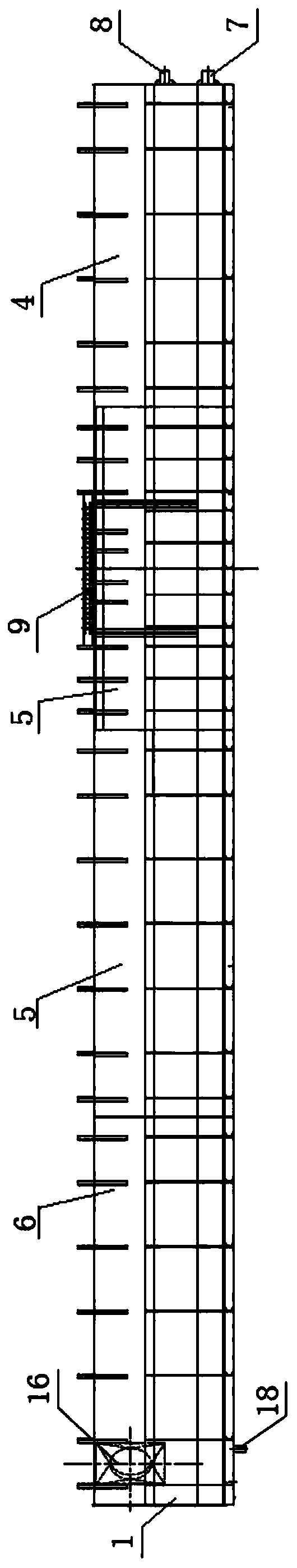

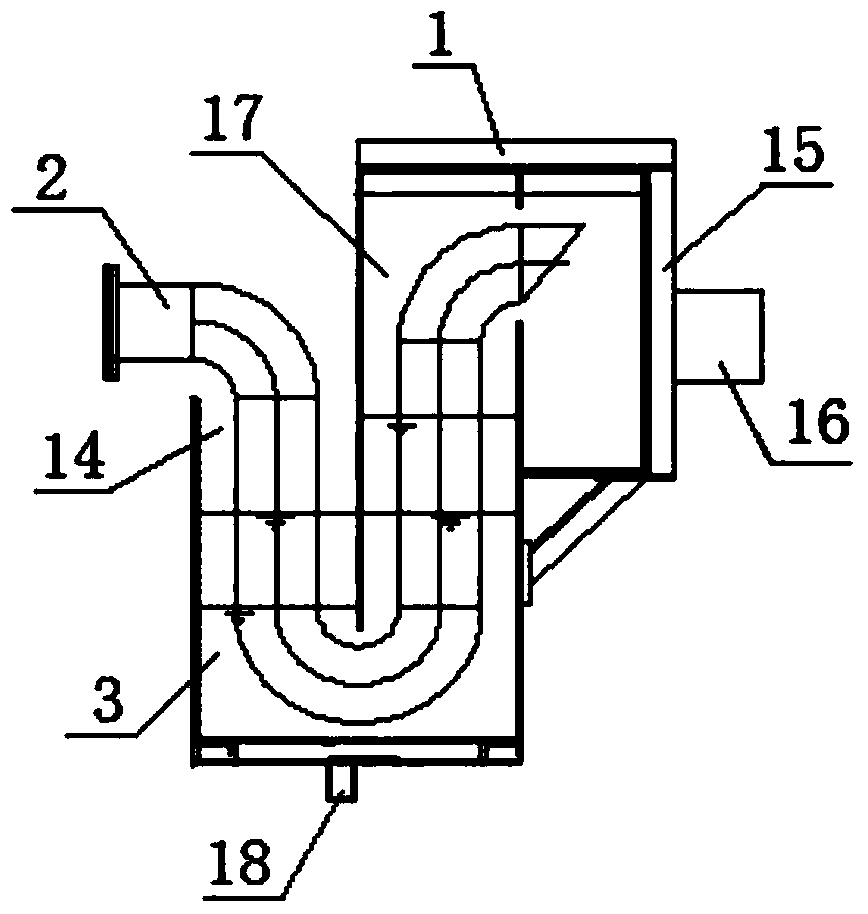

[0022] The present invention will be further explained below in conjunction with the accompanying drawings.

[0023] like Figures 1 to 3 As shown, the water-seal mobile integrated ventilation and dust-removing hood of the present invention includes a ventilation hood groove body 1 and a ventilation pipe 2 . The ventilation hood tank 1 includes the first tank 4, the middle tank 5 and the tail tank 6. The number of the intermediate tanks 5 is greater than or equal to 1. The specific number of the intermediate tanks 5 can be based on the actual movement of the mobile unloading trolley 10. Depending on the distance, the first section of the tank body 4, the middle section of the tank body 5 and the tail section of the tank body 6 are connected by flanges. The fume hood tank body 1 contains an open end 14 and a closed end 15. The closed end 15 is provided with a dust removal air duct interface 16. The fume hood tank body 1 contains a sealed coolant 3. The liquid level and type of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com