Dual-purpose mounting bracket

A mounting bracket, dual-purpose technology, applied in the direction of bumpers, etc., can solve the problem of high production and management costs of mounting brackets, and achieve the effects of avoiding logistics confusion, improving structural strength, and reducing mold costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to help those skilled in the art to accurately understand the subject matter claimed by the present invention, specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

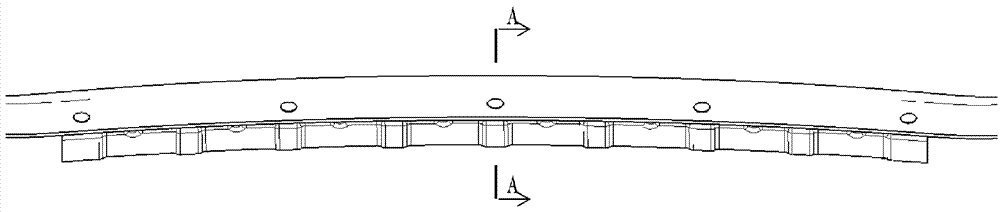

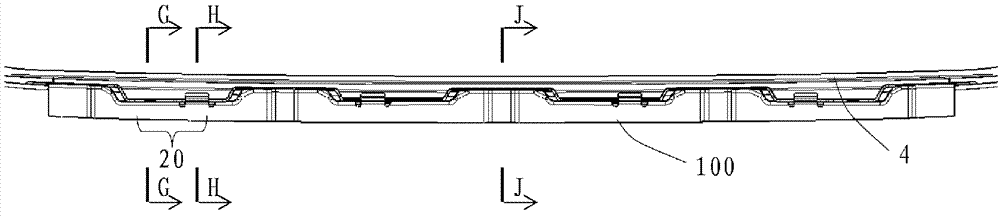

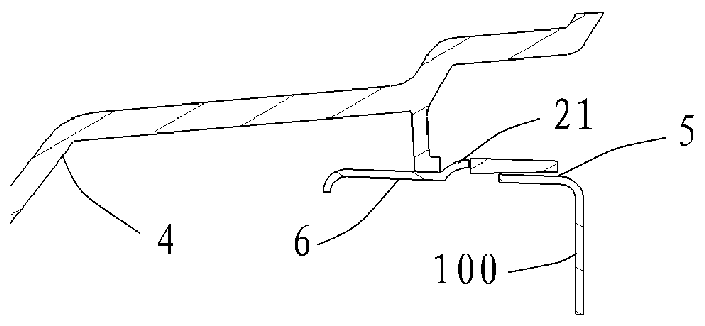

[0032] Image 6 A dual-purpose mounting bracket according to a specific embodiment of the present invention is disclosed, such as Image 6 As shown, a dual-purpose mounting bracket 100 according to a specific embodiment of the present invention is stamped and formed from a metal plate, and has a first surface 5 and a second surface 6 opposite to the first surface 5. The dual-purpose mounting bracket 100 includes The first number of the first installation area 1 and the second number of the second installation area 2; wherein, the first number and the second number are not less than two, the first installation area 1 protrudes to the first surface 5, the second installation Area 2 protrudes to the second surface 6, each first instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com