Touch panel and its light-shielding material

A technology of light-shielding materials and touch panels, which is applied in the direction of instruments, electrical digital data processing, and input/output processes of data processing, etc., and can solve the problems of shortening the life of materials, affecting the beauty and reliability of touch panels, and reducing the operability of light-shielding materials And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

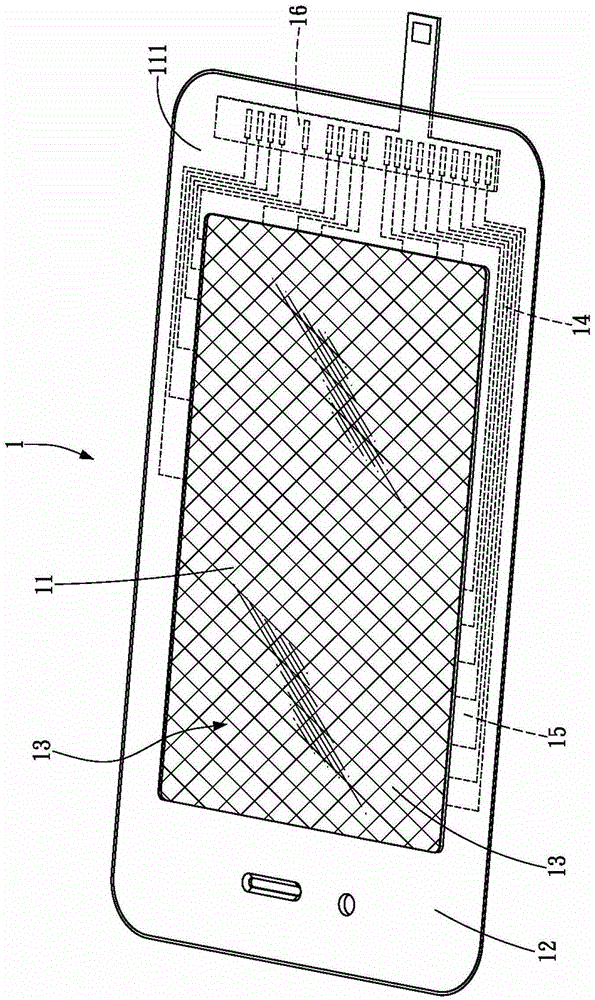

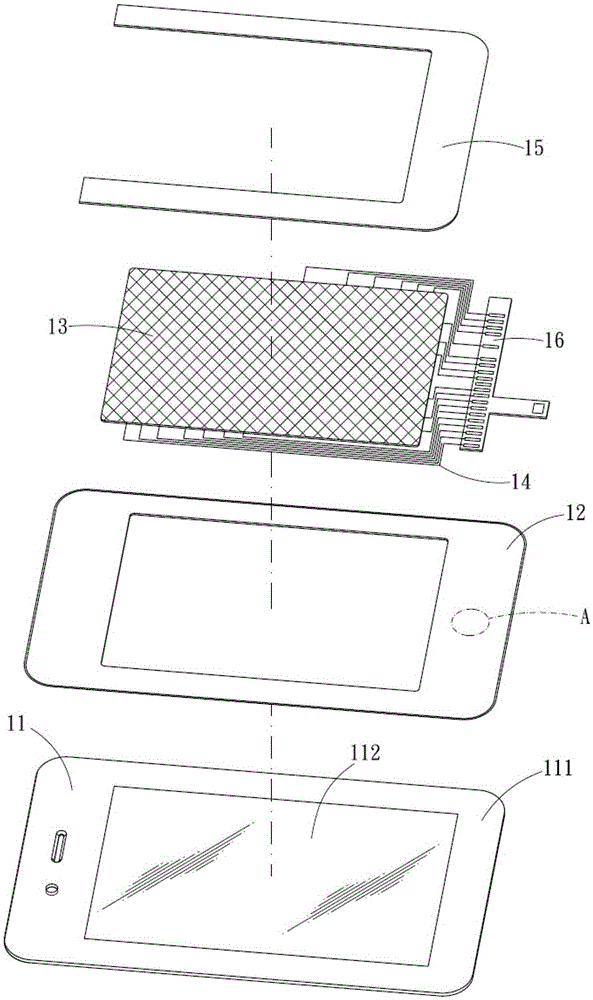

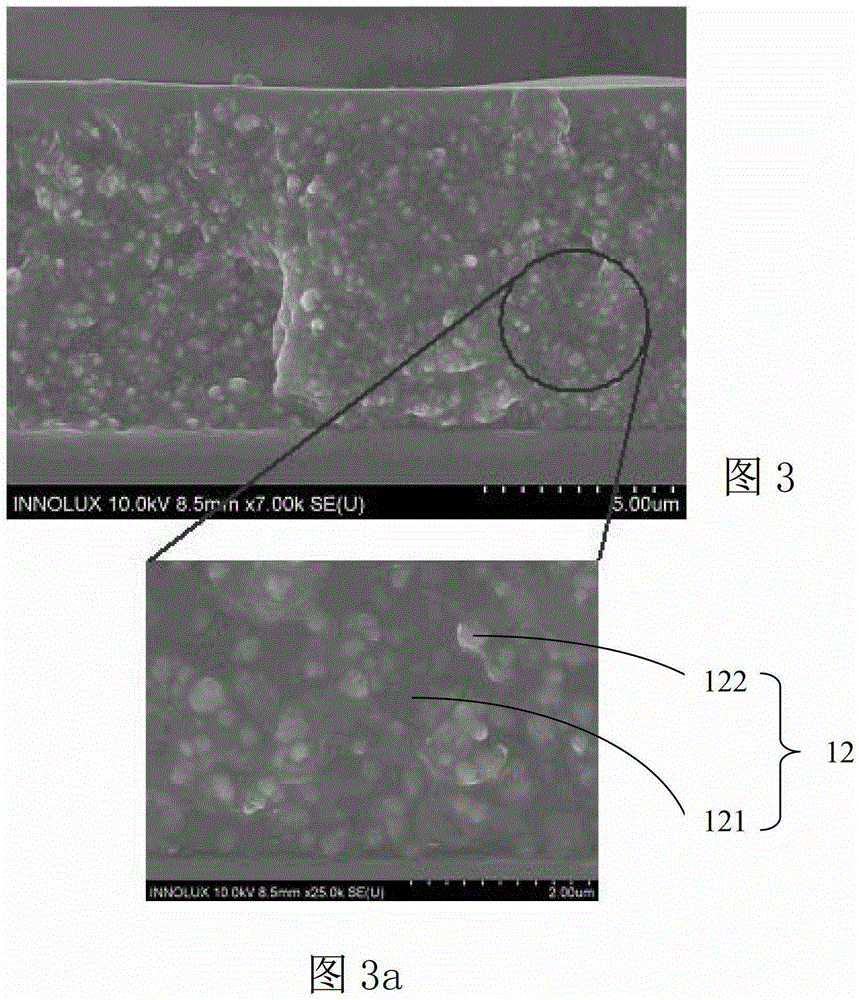

[0029] Please refer to figure 1 and figure 2 , are the application schematic diagram of one embodiment of the present invention and the application schematic diagram of another embodiment, respectively. This embodiment discloses a light-shielding material for coating on the edge of the glass substrate 11 of the touch panel 1, the light-shielding material 12 includes: silica gel 121 and inorganic powder 122, the inorganic powder 122 is mixed in the silica gel 121, the inorganic powder 122 It is used to achieve the function of shielding light and toning, wherein, the silica gel of each embodiment is selected from methyl silica gel or benzene ring silica gel, and the inorganic powder 122 of each embodiment is selected from titanium dioxide, carbon black and combinations thereof. Composed group, but the present invention is not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com