Extrusion sleeve

A technology of extrusion sleeve and chamfering, applied in the field of extrusion sleeve, which can solve the problems of difficult operation, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

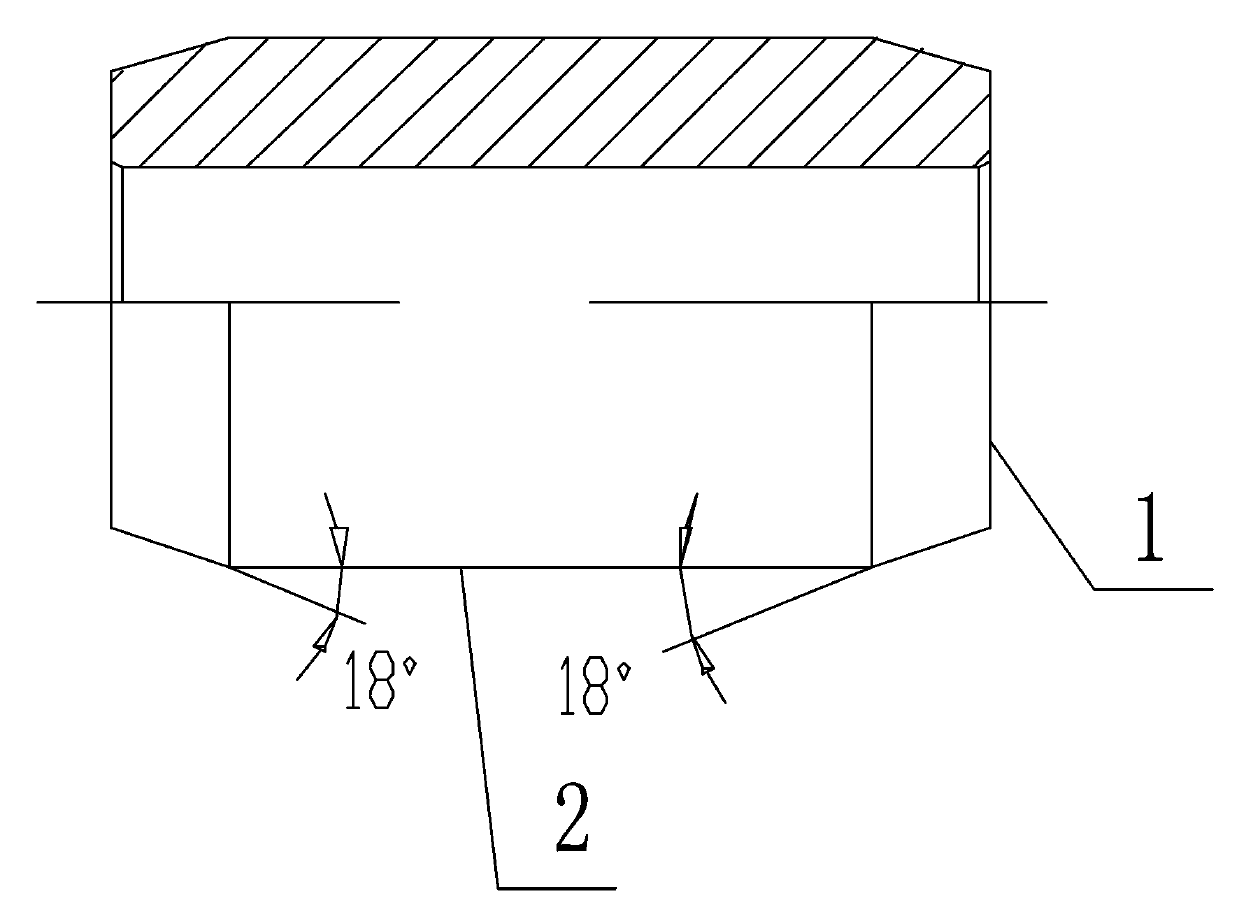

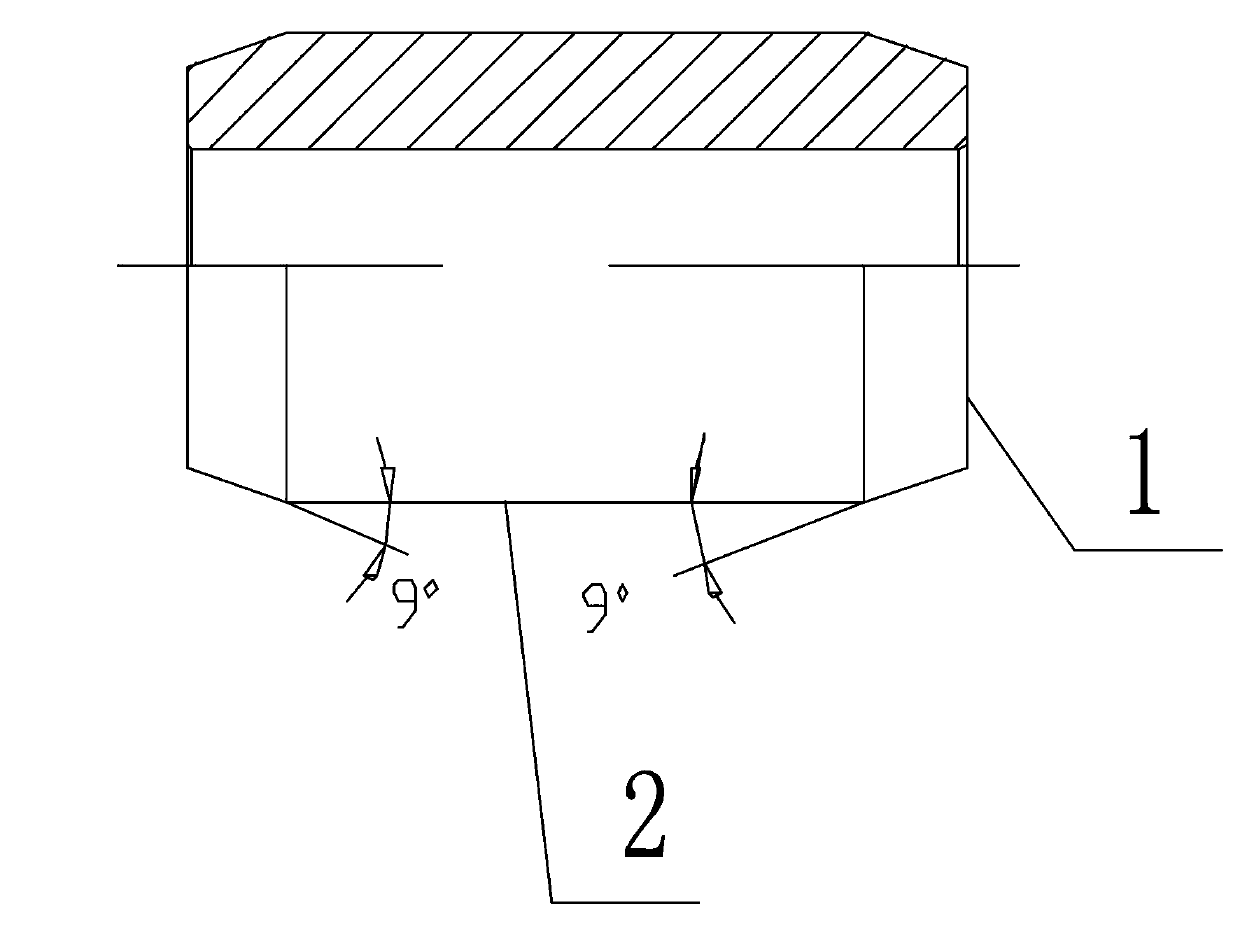

[0011] Such as figure 2 The extrusion sleeve shown is in the shape of a cylinder, and the chamfer between the two end faces 1 of the cylinder and its outer peripheral surface is 9°. Correspondingly, the chamfer can be set to a value between 7° and 15°; or more preferably, a value between 7° and 15°.

[0012] 1. The adjusted chamfer can improve the construction efficiency of the (extrusion sleeve) users (the working pressure is reduced from the original 350KN to 450KN to the current 250KN).

[0013] 2. The reduced weight of the extrusion sleeve itself reduces the transportation cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com