Heat conduction silicon grease coating fixture and heat conduction silicon grease coating method

A heat-conducting silicone grease and coating method technology, which is applied to the device and coating of the surface coating liquid, can solve problems such as unevenness, low coating efficiency, and affecting heat dissipation effects, and achieve consistent coating thickness and improved Good installation quality and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with accompanying drawing, and the embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing, and the following description about the embodiment of the present invention is only exemplary, not in order to limit the subject matter to be protected of the present invention For the embodiments described in the present invention, there are other changes within the protection scope of the claims, which all belong to the subject matter required to be protected in the present invention.

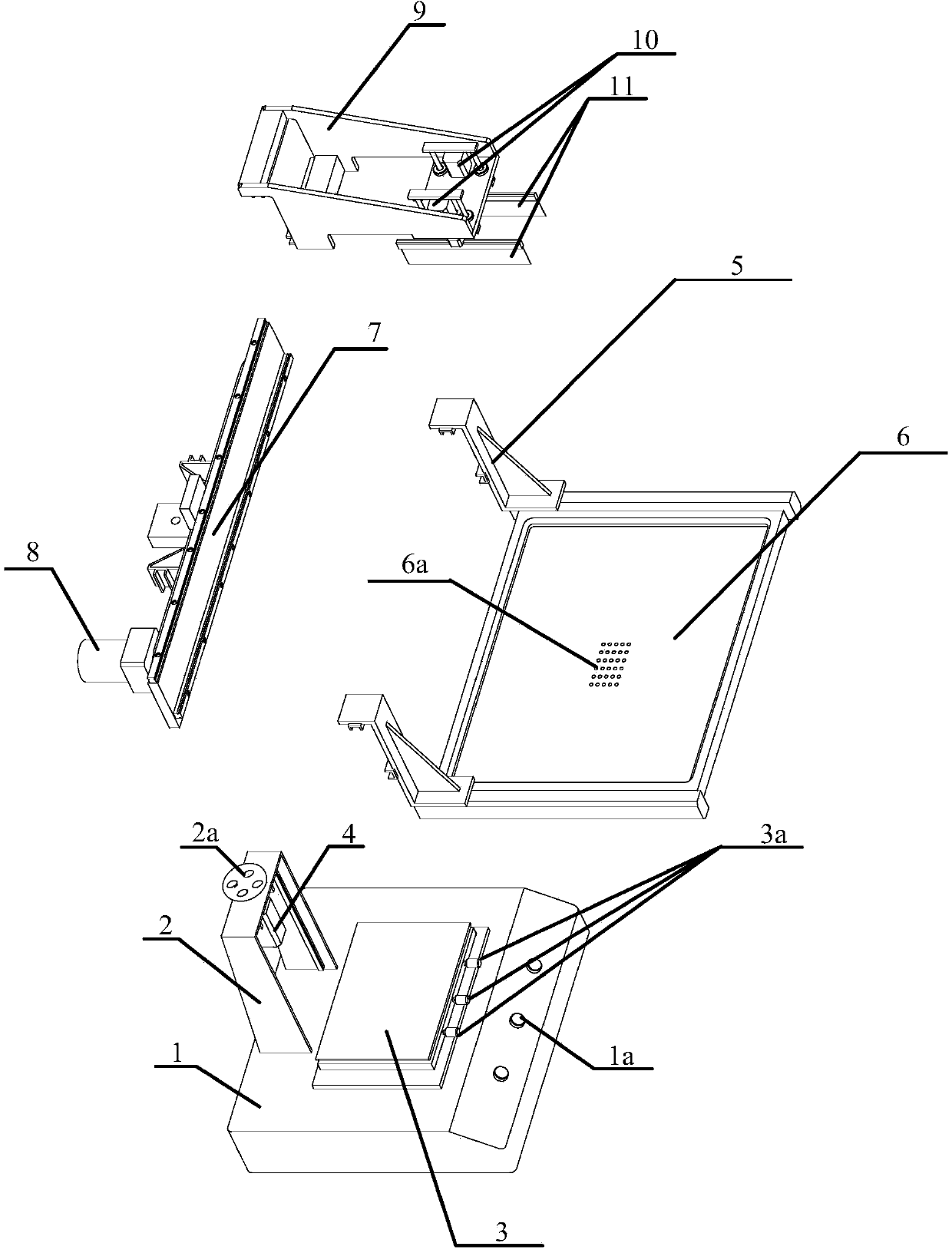

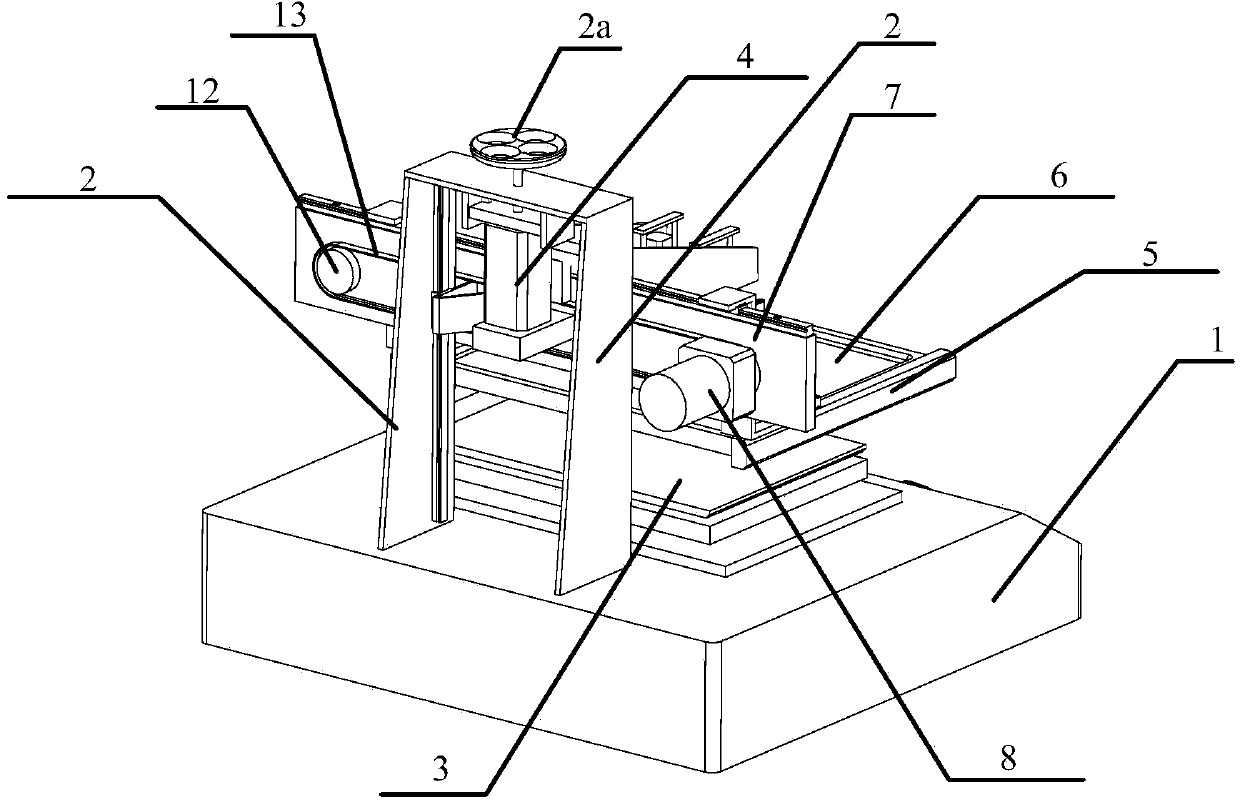

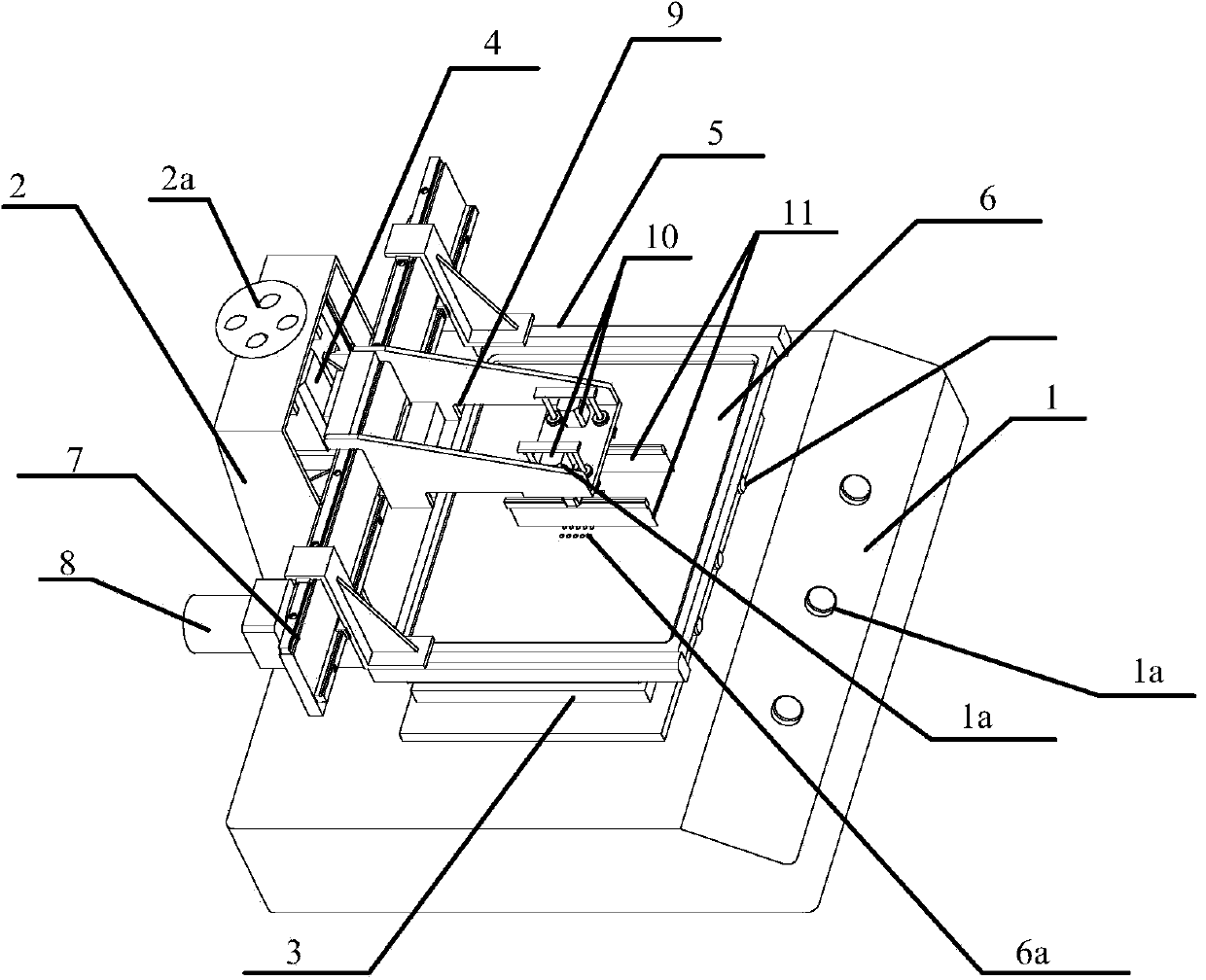

[0025] combine Figure 1 to Figure 3 As shown, the structure of the heat-conducting silicone grease coating tooling is that the stand (2) is fixed on the base (1), the main cylinder (4) is fixed on the upper part of the stand (2) and the head of the main cylinder (4) protrudes The direction is vertically downward; the horizontal frame (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com