Vibration sorting equipment

A device and vibrating plate technology, applied in the field of sorting equipment, can solve problems such as easy damage of parts, and achieve the effect of solving easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

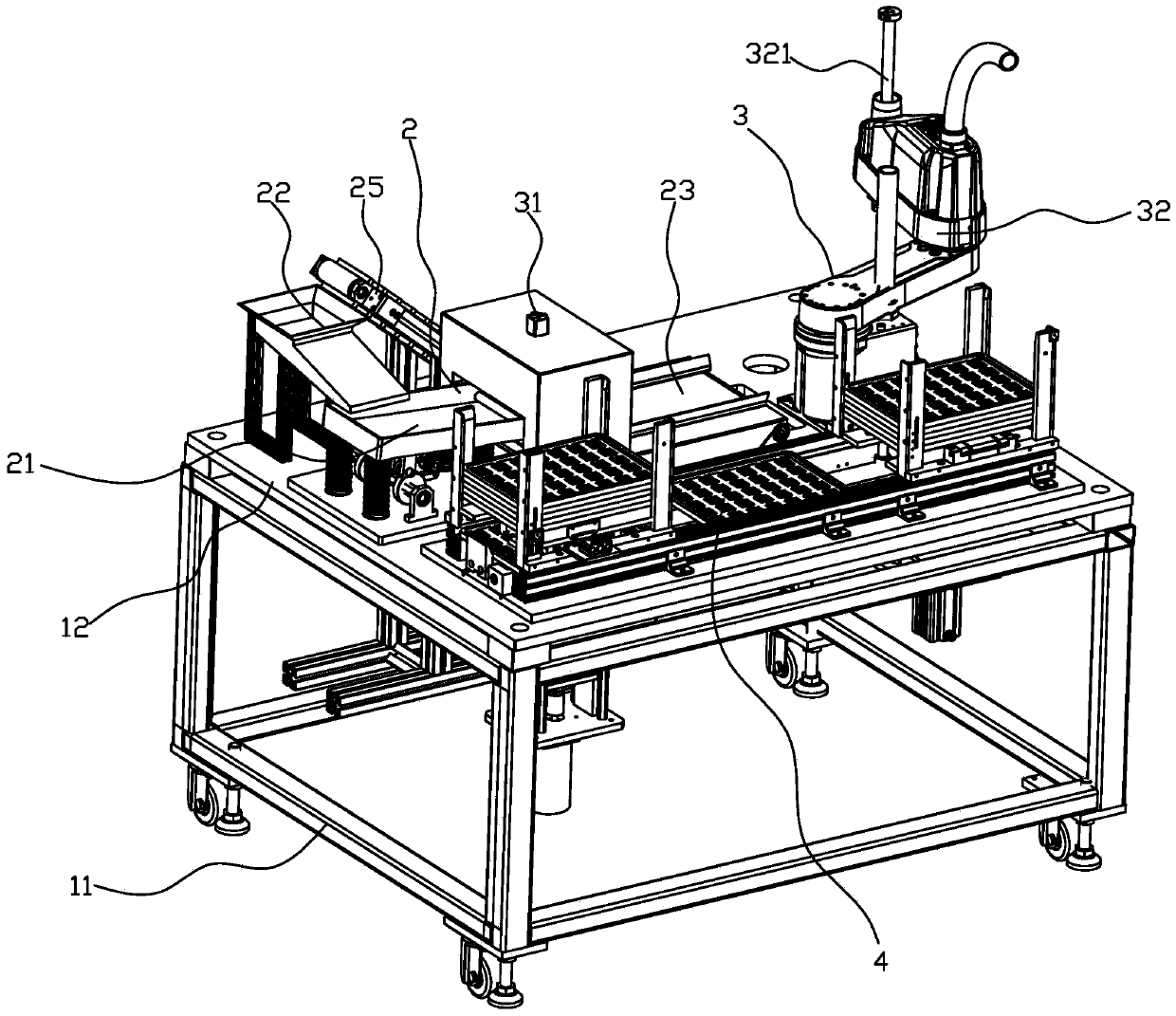

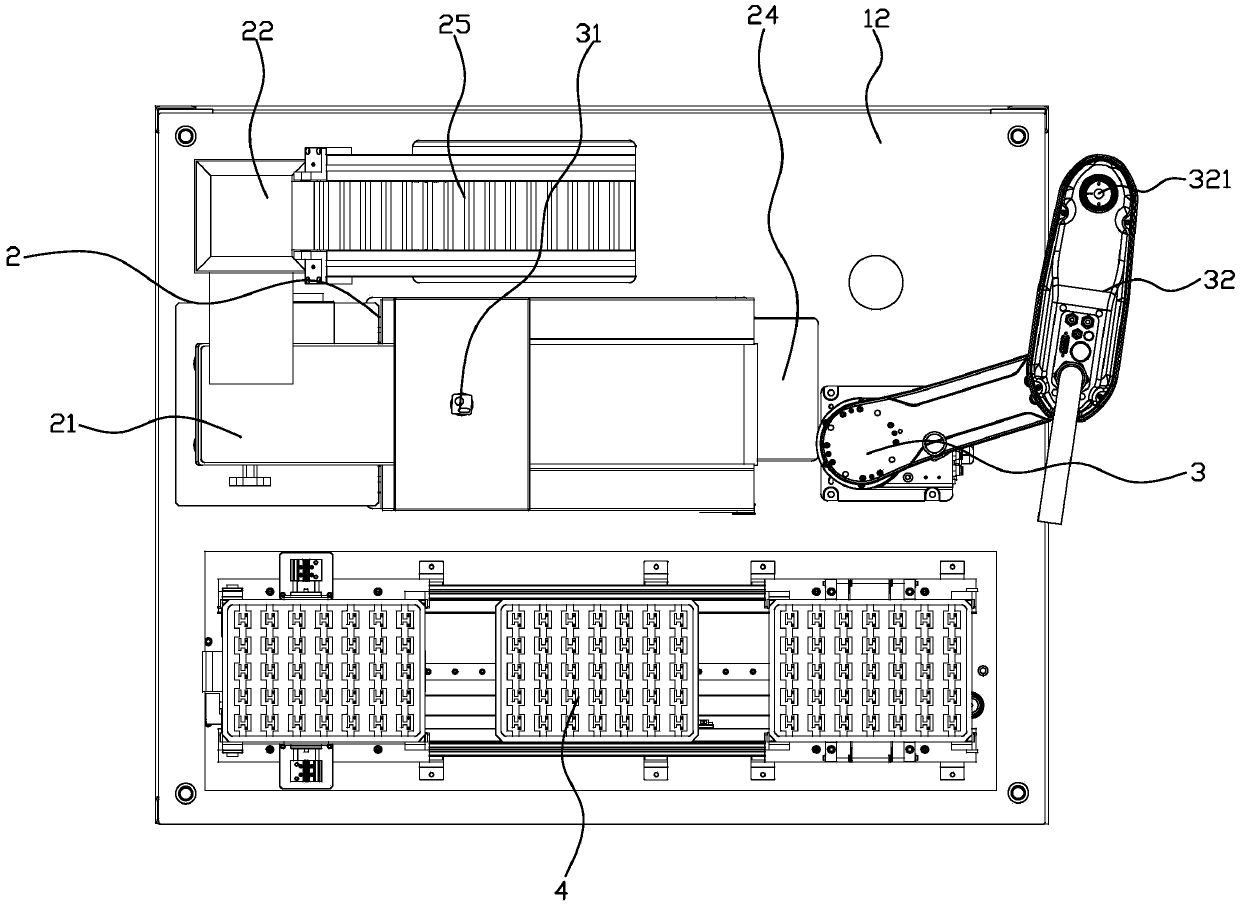

[0029] refer to Figure 1-12 , specifically refer to figure 1 , figure 2 , a vibration sorting device, comprising a mounting frame 11 and a mounting plate 12 arranged on the mounting frame 11, the mounting plate 12 is equipped with a parts vibration dispersion assembly 2, a parts sorting assembly 3 and a parts collection assembly 4, The component vibration dispersing assembly 2 includes a vibration dispersing device 21 .

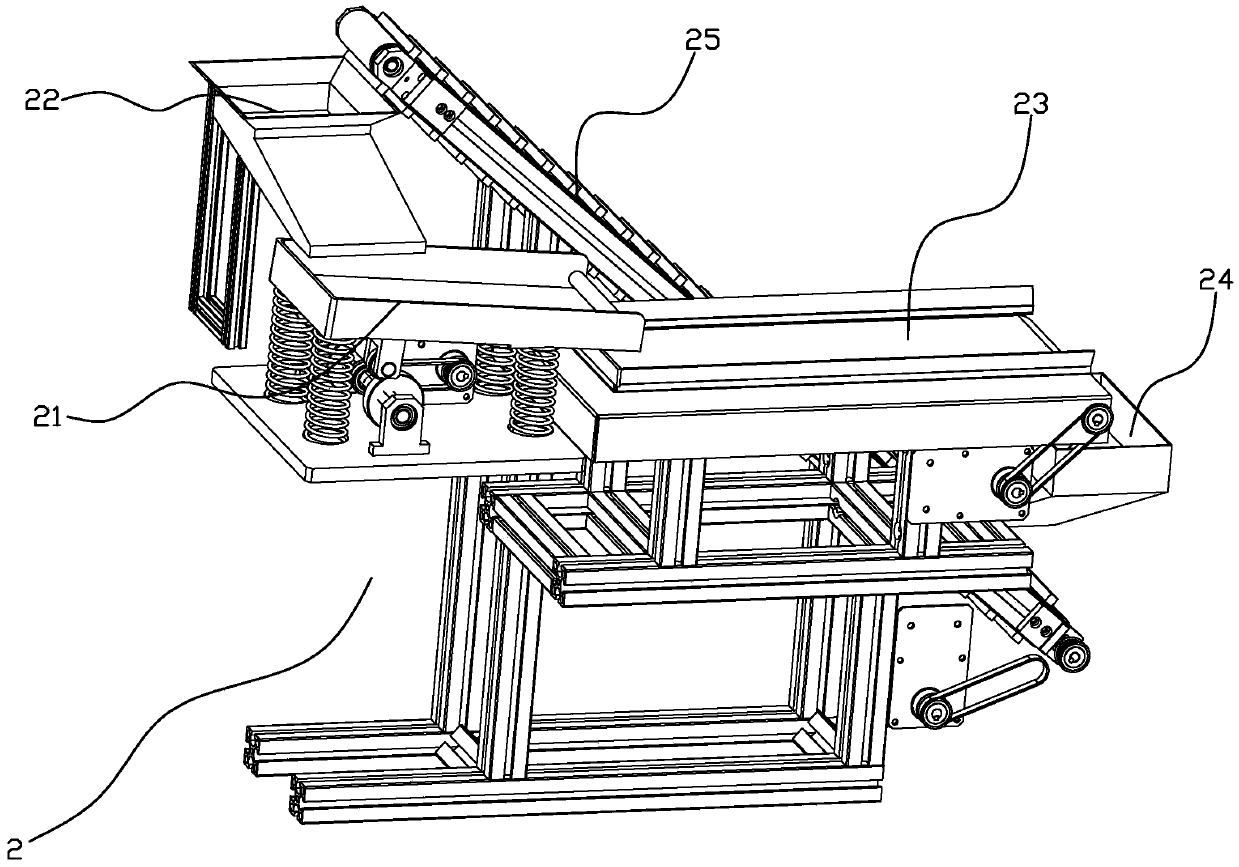

[0030] refer to image 3 , Figure 4 , the parts vibration dispersing assembly 2 includes an upper hopper 22, the above-mentioned vibration dispersing device 21 is arranged at the outlet of the upper hopper 22, the discharge end of the vibration dispersing device 21 is provided with a horizontal conveying device 23, and the horizontal conveying The outlet of the device 23 is provided with a lower hopper 24 , and the outlet of the lower hopper 24 is provided with a backflow conveyor device 25 , and the backflow conveyor device 25 can recycle parts into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com