Material guide device

A technology of a material guide device and a material guide tube, which is applied in the field of steel rolling equipment, and can solve the problems of large jumping of the binding parts, safety accidents, and large friction, and achieve the effects of reducing scratch rate, preventing jumping, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

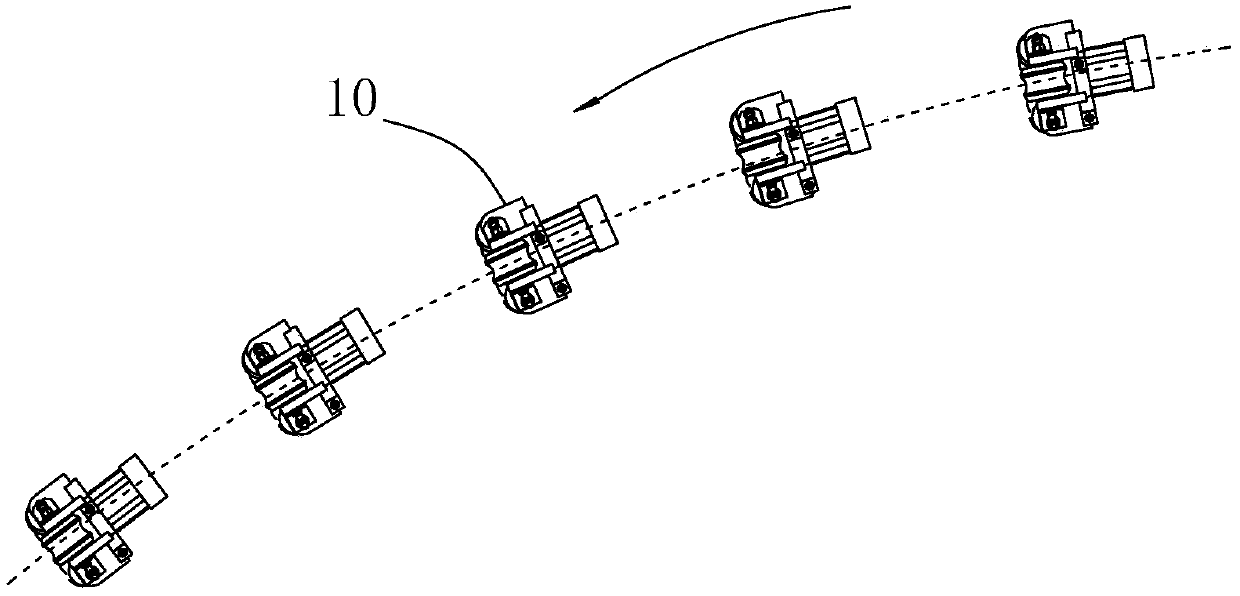

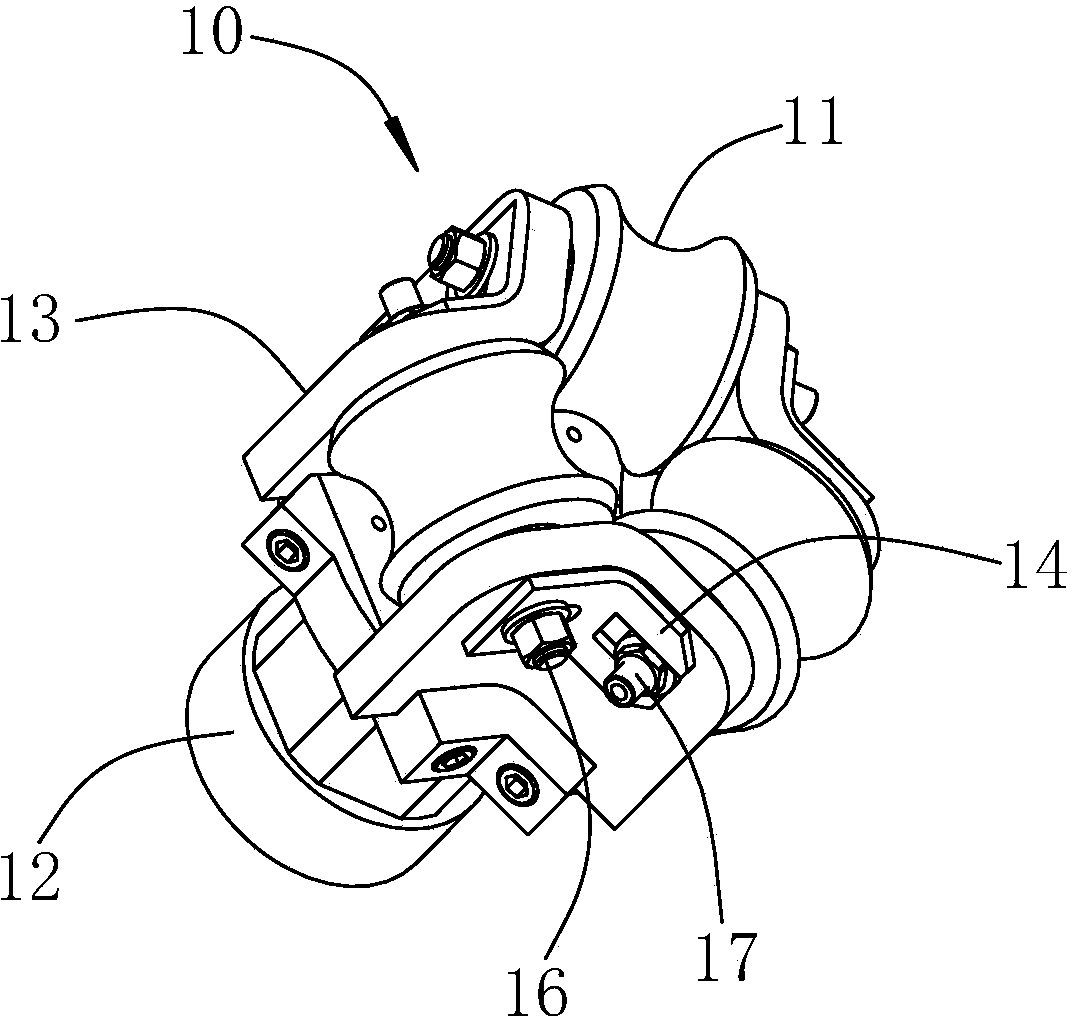

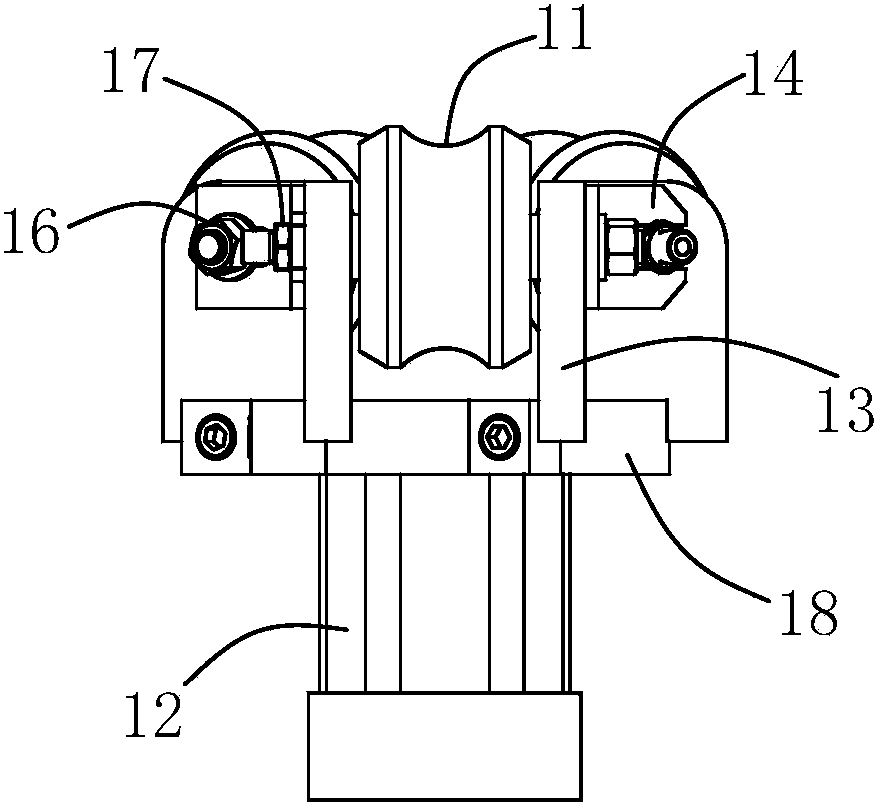

[0011] like figure 1 , 2 As shown, the material guide device is composed of a number of material guide unit sections 10 arranged at intervals along an arc track, and the adjacent material guide unit sections 10 are arranged correspondingly from the end to the end. The material guide unit section 10 is surrounded by three guide rollers 11. The axes of the guide rollers 11 are generally located on the same plane, arranged in pairs at an angle of 60°, and the feeding end of the material guide unit section 10 is provided with a guide tube 12, the lumen of the guide tube 12 is surrounded by three guide rollers 11 The guide area is arranged successively. The material guide device is mainly to change the traditional sliding conveying of the binding parts into rolling conveying, so as to reduce the scratch rate and jumping of the binding parts. When the end and the end enter the material guide device, stable guiding conveying is carried out to prevent the large-scale jumping of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com