Six-freedom-degree control blocking type flexible section bar three-dimensional stretch bending die and forming process

A stretch-bending mold and segmented technology, which is applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of long production cycle, damage to the mechanical strength of parts, and large forming errors, so as to reduce manufacturing costs and save The cost of mold repair and the effect of eliminating steep bends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

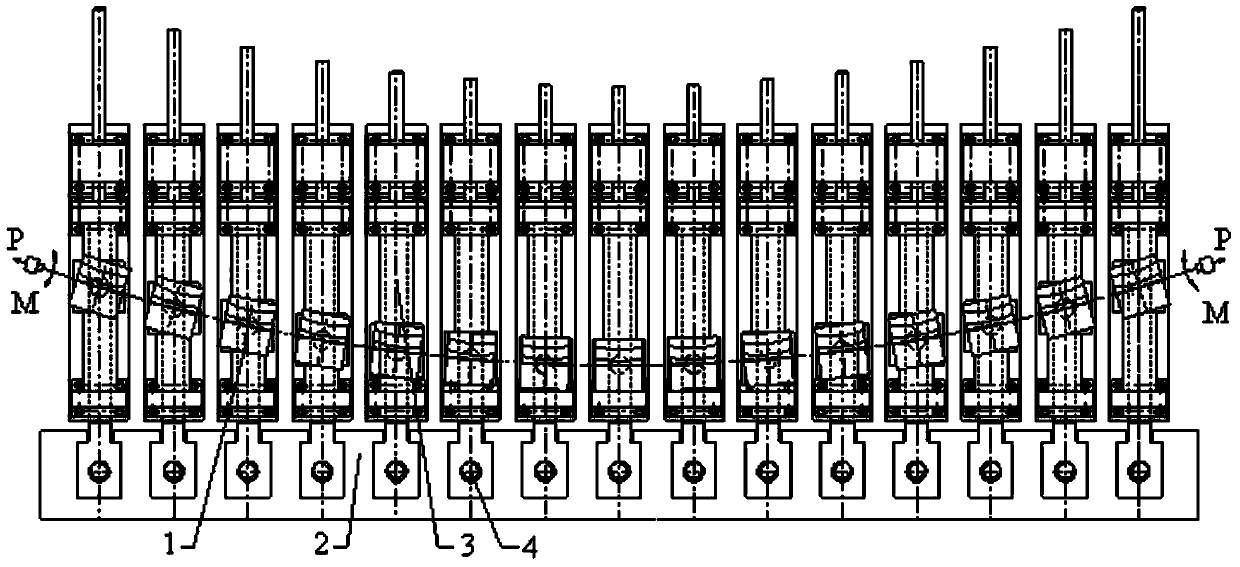

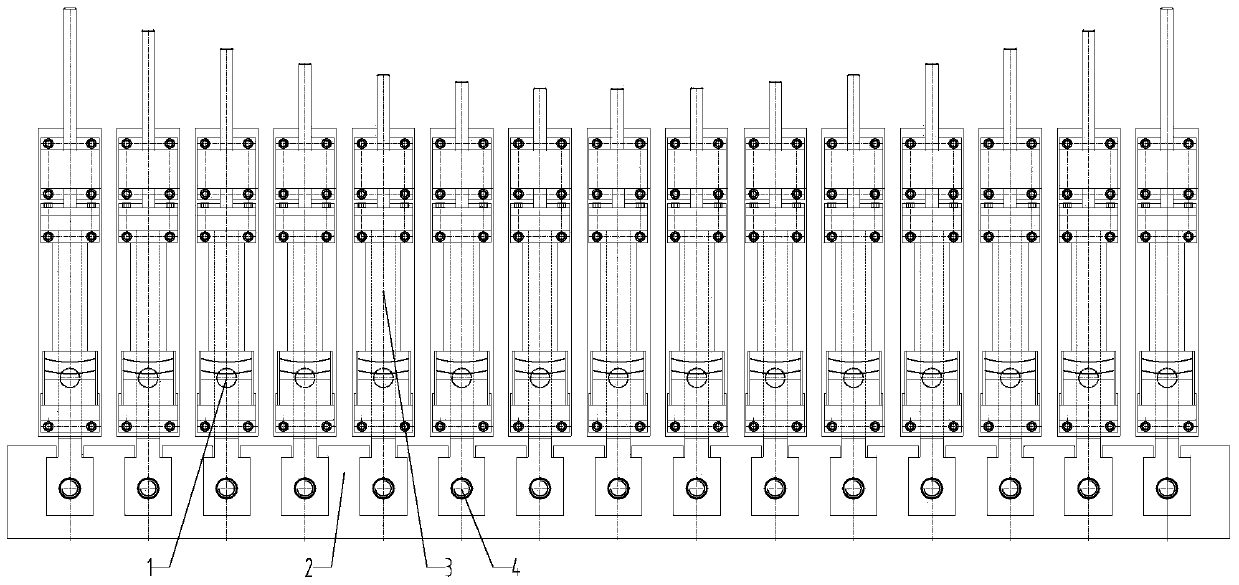

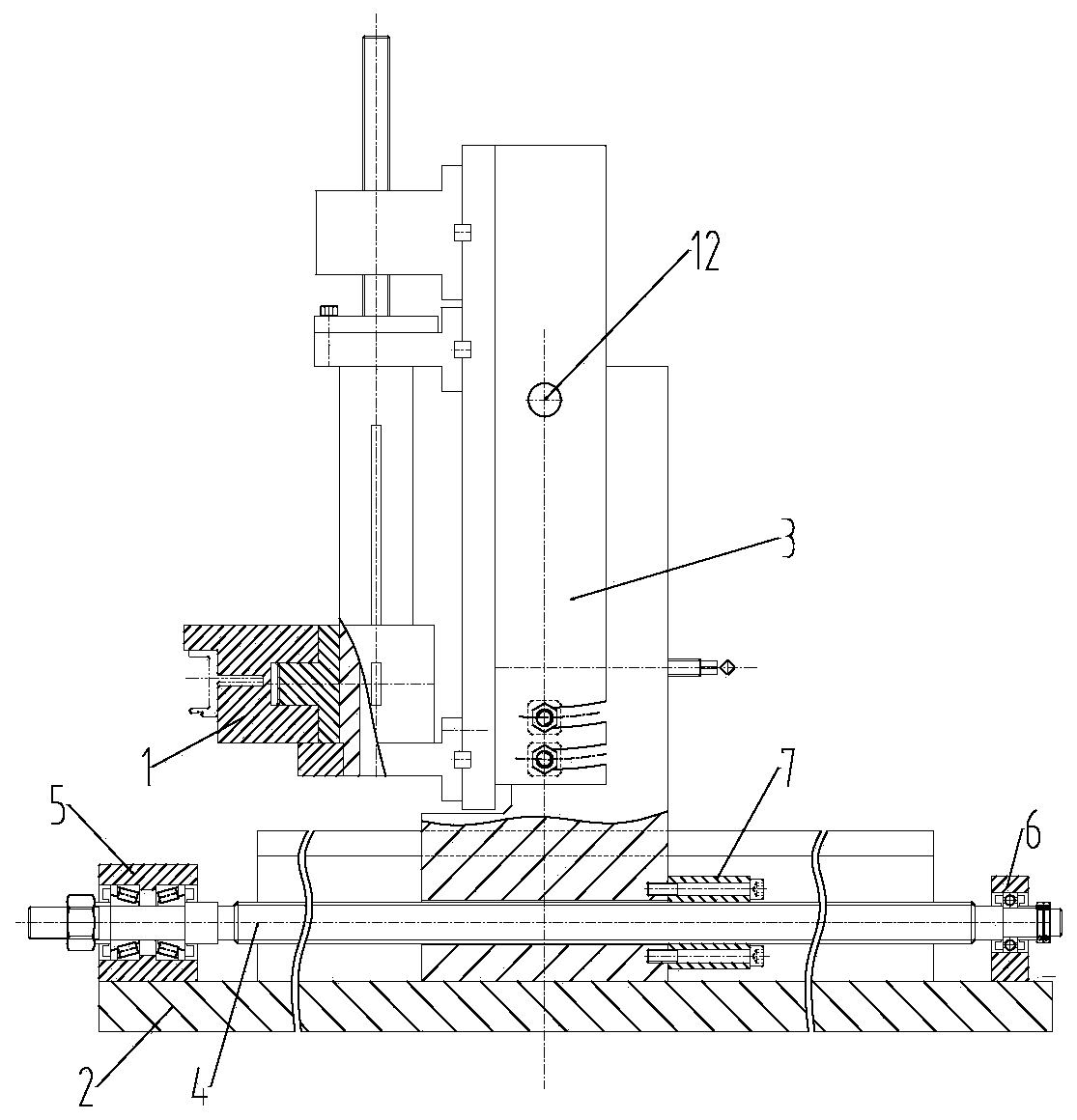

[0041] Further illustrate the specific content of the present invention below in conjunction with accompanying drawing:

[0042] The mold is mainly composed of a forming curved surface module 1, a mold base 2, several identical adjustable supports 3 and a lead screw 4. The mold base 2 is provided with rectangular guide grooves parallel to and equidistant along the longitudinal direction, and a lead screw 4 and lead screw fixing bearing devices 5, 6 are installed. The adjustable bracket 3 is installed by the bottom rectangular guide part of the column 8 on it and the rectangular guide rail groove on the mold base 2, and the front and rear movement and positioning are realized through the lead screw 4 and the transmission nut 7, thereby controlling the shape of the curved surface module 1. The first degree of freedom of movement. The left and right positions of each adjustable bracket 3 are determined by the position of the rectangular guide groove of the mold base 2 , that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com