Automobile shock absorber piston wrapping film prepressing die

A technology of automobile shock absorbers and rubber-covered sheets, which is applied in hand-held tools, manufacturing tools, metal processing, etc., can solve the problem of high cost and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

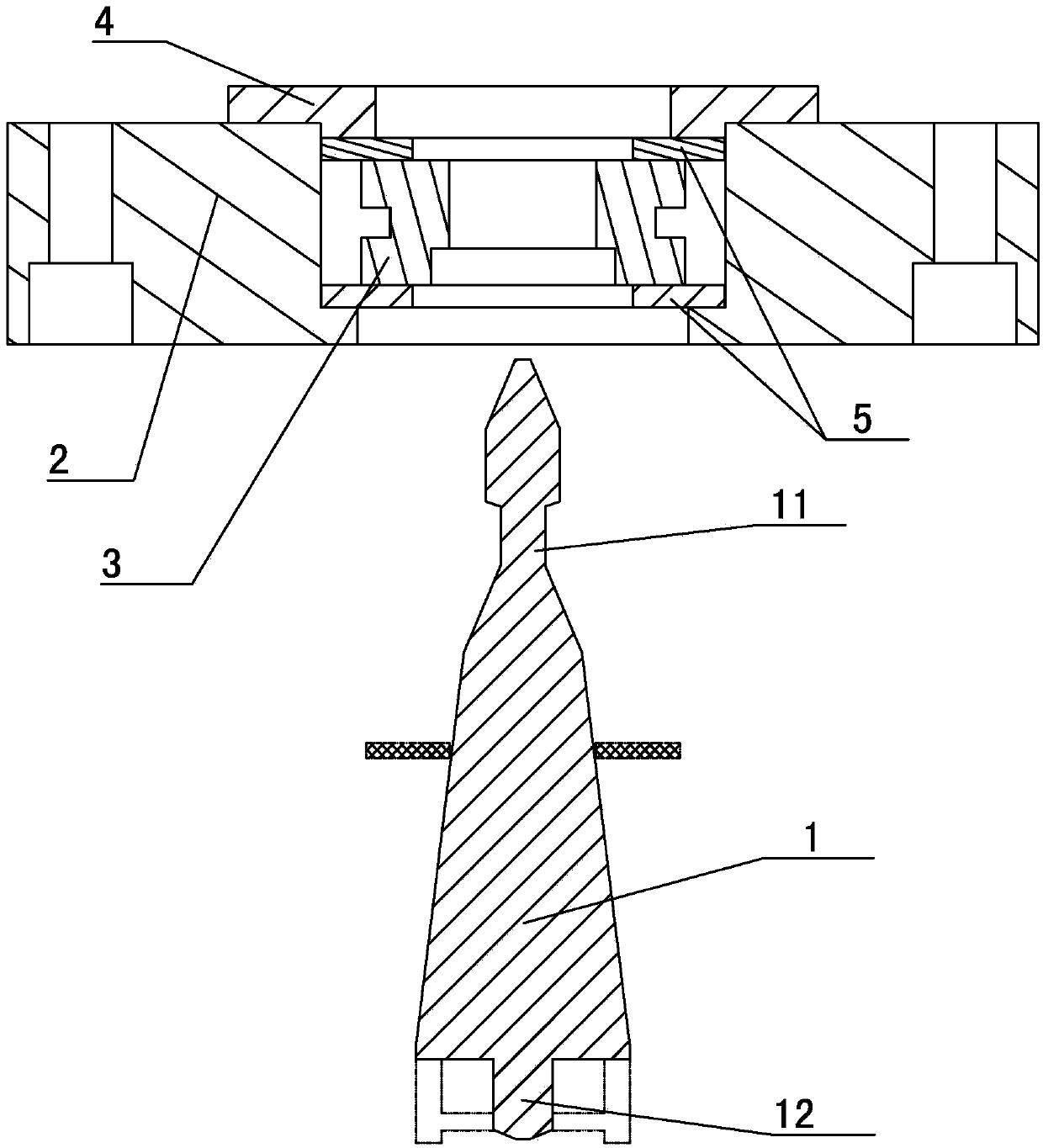

[0016] Example 1 figure 1 Shown is a pre-compression mold for automobile shock absorber piston covering film, which includes a cone mold 1 for covering the film and a compression mold set on the cone mold 1 to wrap the piston after being pressed down; the compression mold includes a positioning mold 2. The core 3 arranged in the core cavity of the positioning die 2 and the positioning flange 4 used to lock the core 3 in the core cavity. Among them, the mold core 3 is made of hard metal or hard metal alloy such as iron or stainless steel, which will not be significantly deformed due to changes in temperature, has good quality of encapsulation, and has a relatively long service life.

[0017] In addition, a gasket 5 is provided between the positioning mold 2 and the mold core 3 and between the mold core 3 and the positioning flange 4. One is to prevent the mold core 3 from directly colliding with the positioning mold 2 and the positioning flange 4 during the working process of the ...

Embodiment 2

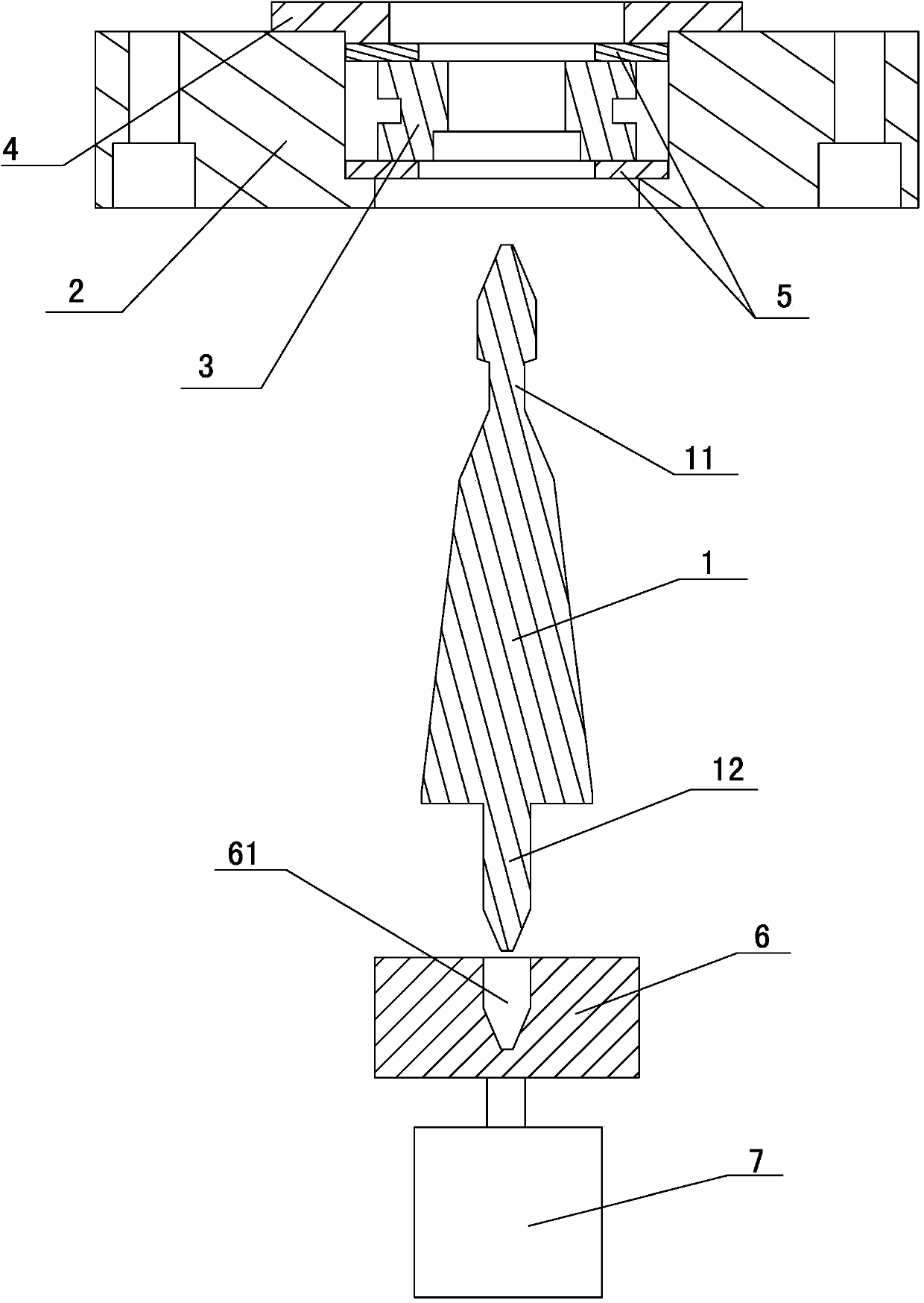

[0019] Example 2 such as figure 2 As shown, it is basically the same as the pre-compression mold for the automobile shock absorber piston wrap film of Example 1, including a cone mold 1 and a compression mold composed of a positioning mold 2, a core 3 and a positioning flange 4. The upper part of the cone mold 1 is provided with a The difference is that the center of the bottom of the cone mold 1 is coaxially provided with a positioning column 12 passing through the center hole of the piston, and it also includes a positioning block 6 for placing the piston. 6 is provided with a positioning hole 61 that matches the positioning column 12, which can ensure the consistency of the positioning of the piston and the cone mold 1, thereby stabilizing the encapsulation effect; preferably, the bottom of the positioning column 12 is a truncated cone with a large upper and a smaller bottom. , The bottom of the positioning hole 61 is a frustum hole matching the frustum.

[0020] In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com