Wear-resistant halving stick for mould processing

A technology for mold processing and centring rods, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of easy wear, reduced service life, easy to be magnetized, etc., to achieve long service life, simple structure, Guarantee the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing description and specific embodiment:

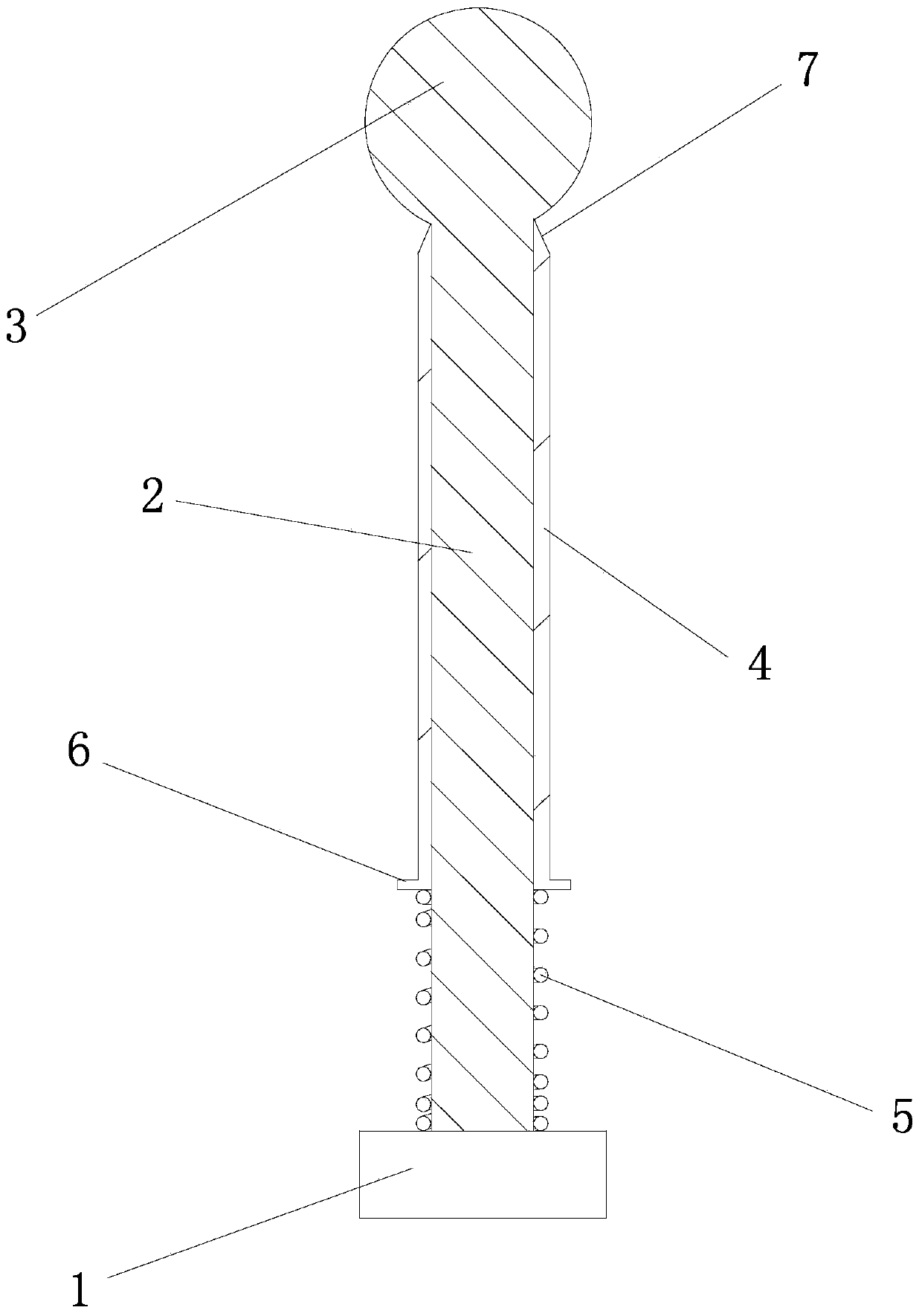

[0013] Such as figure 1 The shown wear-resistant centering rod for mold processing includes a rod end 1, a rod body 2 is arranged on the rod end 1, and a steel ball 3 is arranged on the end of the rod body 2, A ceramic sleeve 4 is sheathed on the outer side of the rod body 2 , and a pressing spring 5 capable of pressing the ceramic sleeve 4 against the steel ball 3 is provided between the ceramic sleeve 4 and the rod end 1 .

[0014] In the present invention, a position-limiting protruding ring 6 is provided at the lower end of the ceramic sleeve 4, one end of the pressing spring 5 presses on the position-limiting protruding ring 6, and the other end of the pressing spring 5 presses on the rod end 1 .

[0015] The diameter of the steel ball 3 in the present invention is 2mm. A tapered surface 7 is provided on the outer wall of the uppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com