Flour mixing equipment for noodle processing

A technology for noodles and equipment, applied in applications, dough mixers, mixing/kneading of horizontal installation tools, etc., can solve the problems of high manual participation, different degrees of softness and hardness, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

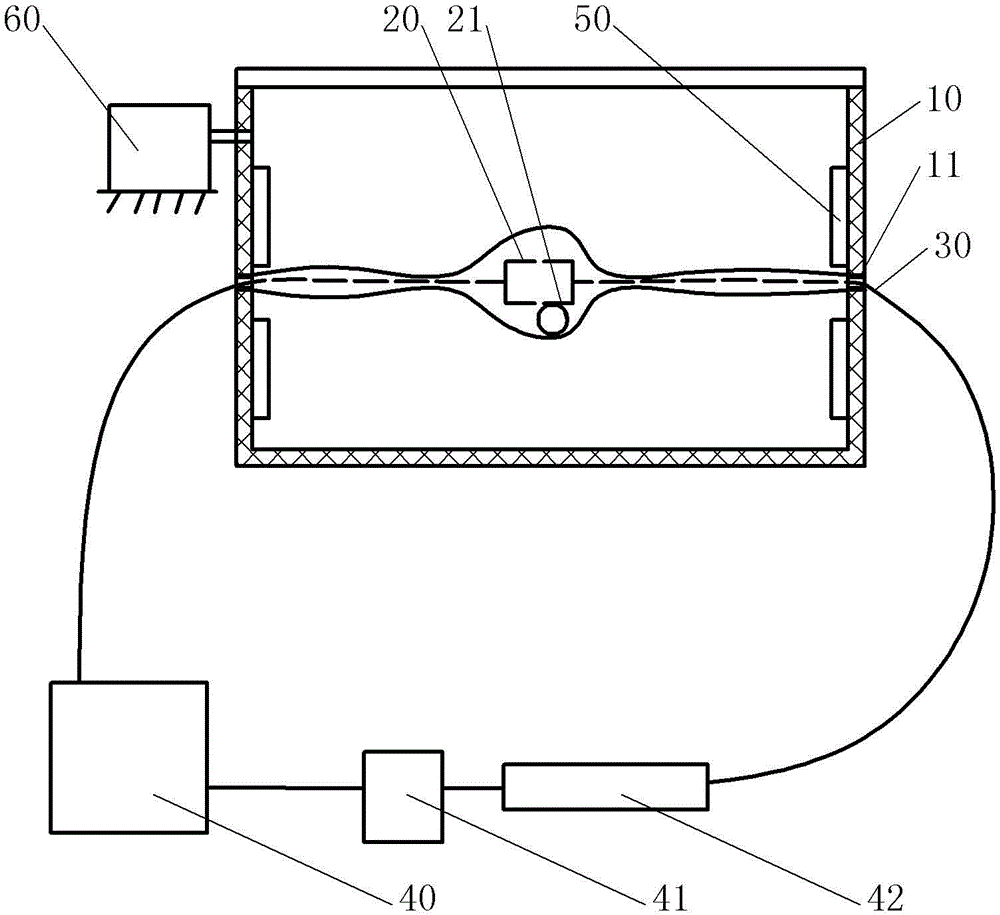

[0018] The reference numerals in the drawings of the description include: barrel 10 , sliding sleeve 11 , sleeve 20 , rolling element 21 , coil 30 , AC power supply 40 , frequency converter 41 , sliding rheostat 42 , stator 50 , and vacuum pump 60 .

[0019] The embodiment is basically as attached figure 1 Shown:

[0020] The noodle kneading equipment for noodle processing includes an aluminum alloy barrel 10 sealed with a cover installed on the barrel 10; it also includes a vacuum pump 60, an AC power supply 40, a mover and a stator 50, wherein the stator 50 is a permanent magnet and is arranged on the barrel. On the inner wall of 10, the mover is a sleeve 20 with a coil 30 inside and is located in the barrel. The two ends of the coil 30 are slidably connected to the barrel 10. On: the barrel 10 is provided with a suction head, and the vacuum pump 60 is located outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com