Pneumatic reversing solenoid valve

A reversing solenoid valve and pneumatic technology, applied in the field of solenoid valves, can solve problems such as failure to guarantee the normal operation of the solenoid valve, failure of the solenoid valve to work normally, loss of electromagnetic suction, etc., to achieve no magnetic residue, avoid outward injection, and improve utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

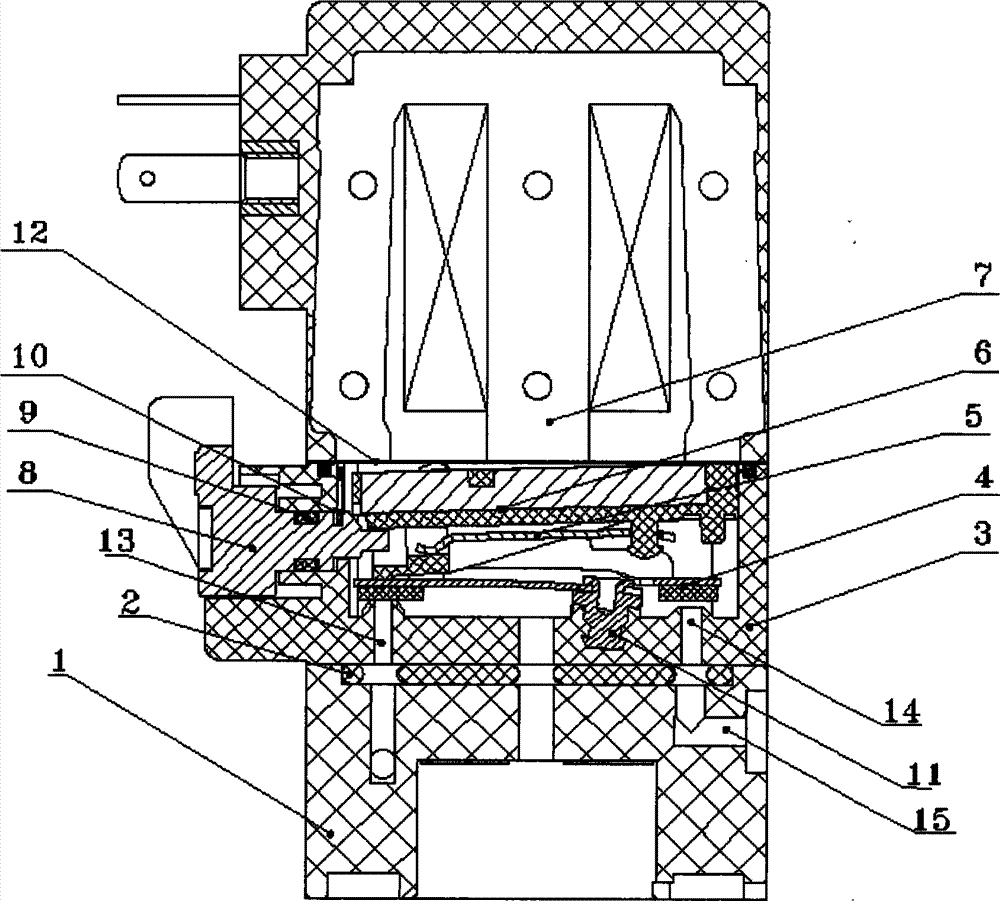

[0012] Such as figure 1 As shown, a pneumatic reversing solenoid valve includes a pilot valve seat 1, a pilot valve seat 3, a coil 7, a moving iron core 6 and a sealing support 4, and the coil 7 is provided with a static iron core, which is composed of Silicon steel sheets are stacked, the static iron core includes 5-8 silicon steel sheets, the silicon steel sheets are in the shape of a mountain, the moving iron core 6 is located directly below the coil 7, the moving iron core 6 and the coil 7 A sealing sheet 12 is connected between them, the moving iron core 6 is rectangular, and the moving iron core 6 is covered with a rubber layer. The valve seat 3 is connected, and the bottom of the pilot valve seat 3 has a through hole. The left side of the through hole is opened with an air intake channel 13, and the right side is opened with an exhaust channel 14. The air intake channel 13 is connected to one end of the sealing bracket 4. Matching, the exhaust channel 14 is matched wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com