Method for preparing micro-nano PSS (Patterned Sapphire Substrate) by photoetching of nano flexible film

A kind of soft film, micro-nano technology, applied in the direction of nanotechnology, electrical components, circuits, etc., can solve the problems of poor exposure time, energy and other parameters, reduce the service life of the soft film, and long exposure time, etc., to achieve cost Low, improve work efficiency, high work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The method for preparing micro-nano PSS by nano soft film lithography in the present invention is realized through the following steps:

[0024] The first step, uniform glue: first, get a sapphire substrate 5, such as figure 1 As shown, a layer of photoresist 4 is evenly coated on the base layer of the sapphire substrate 5, such as figure 2 As shown, the thickness of the photoresist is between 1um. In this step, the photoresist can be a positive resist or a negative resist. This embodiment takes the positive resist as an example for further description.

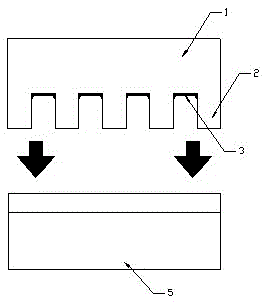

[0025] The second step, exposure: move the sapphire substrate under the soft film, such as image 3 As shown, the soft membrane includes a soft membrane main body 1, the soft membrane main body 1 is in the shape of a cuboid, and a comb group is arranged on one side of the long axis direction of the soft membrane main body 1. Teeth 2 are jointly formed, and a highly reflective metal layer 3 is also provided on the i...

Embodiment 2

[0029] The method for preparing micro-nano PSS by nano soft film lithography in the present invention is realized through the following steps:

[0030] The first step, uniform glue: first, get a sapphire substrate 5, evenly coat one deck photoresist 4 on the base layer of sapphire substrate 5, the thickness of photoresist is 1.1um, in this step, photoetching The glue can be a positive glue or a negative glue. In this embodiment, the positive glue is taken as an example for further description.

[0031] The second step, exposure: move the sapphire substrate to the bottom of the soft film, the soft film includes a soft film main body 10, the soft film main body 10 is in the shape of a cuboid, a comb is arranged on one side of the long axis direction of the soft film main body 10 The tooth group, the comb tooth group is composed of a number of parallel and equidistant comb teeth, and a high reflective metal layer 11 is also provided on the inner wall of the groove formed by two a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com