Improved roller separating device for separating injection product and material rod

A technology for injection molding products and separation devices, which is used in solid separation, sieves, grilles, etc., can solve the problems of high precision requirements of robots, long production lead-in cycles, incomplete root sorting, etc., and achieves strong versatility. The effect of low manufacturing cost and low replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

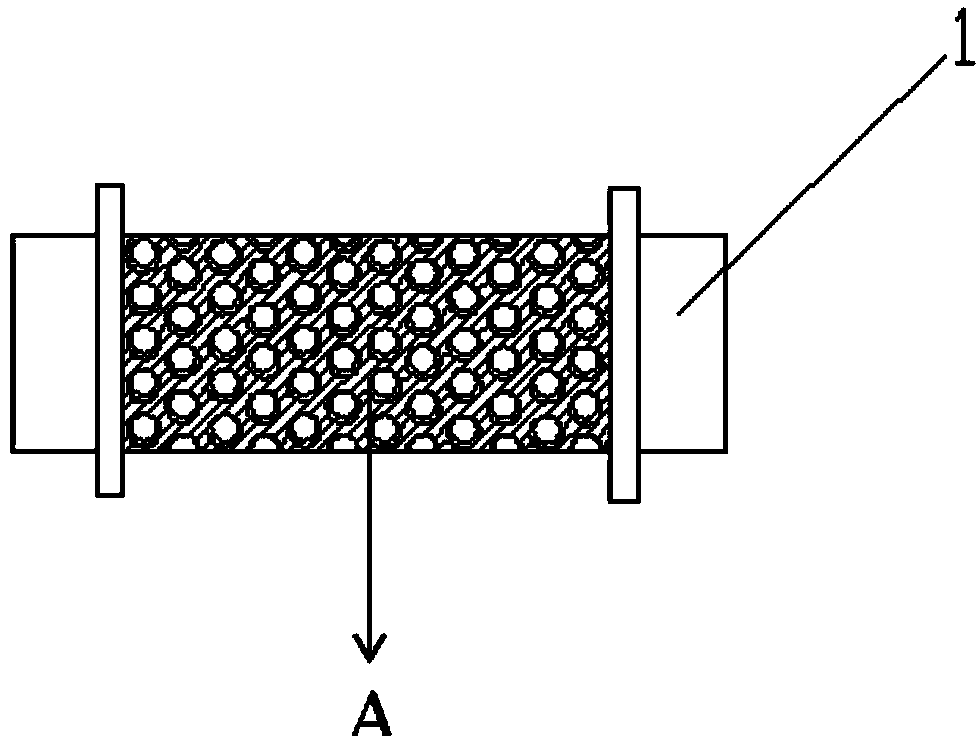

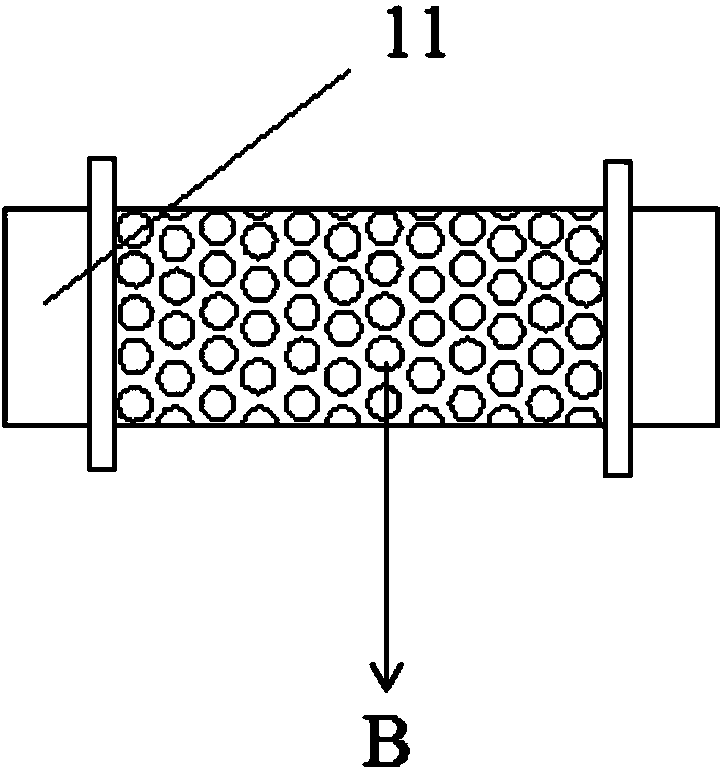

[0030] Such as Figure 1-7 As shown, an improved roller separation device for separating injection molded products from material rods includes a screening roller set 1 , a feeding guide plate 2 , a driving motor 3 and a roller support frame 4 .

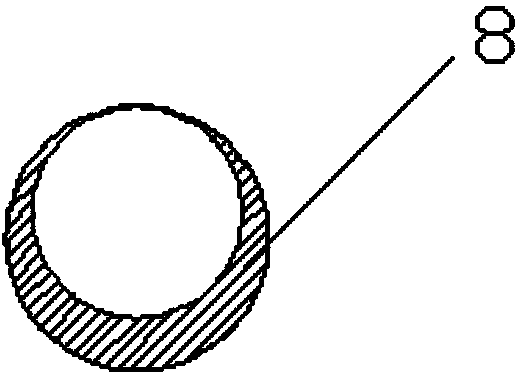

[0031] The screening drum kit 1 is assembled from a drum 11 first customized into a honeycomb shape and a soft film 7 that is further processed into a honeycomb shape according to the shape of the product and the rod. It is necessary to ensure that the diameter of the hole of the soft film d<the diameter of the plug hole of the drum D , understand the parameters of the drum aperture spacing, and calculate the size parameters of the soft film according to the actual product and the size of the root; thus quickly cut the film for the separation of the root of the new product.

[0032] Described feeding guide plate 2 must stretch in the drum. The drive motor 3 is a slow AC motor. The roller supports 4 height adjustable.

[0033] When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com