Sealing device with compensation capability for each direction of movement

A technology of sealing equipment and equipment, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., and can solve the problem of not having the ability to rotate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

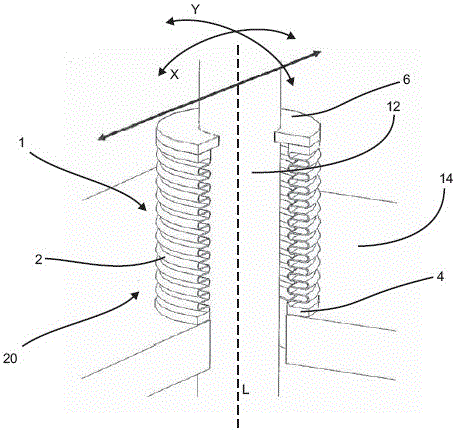

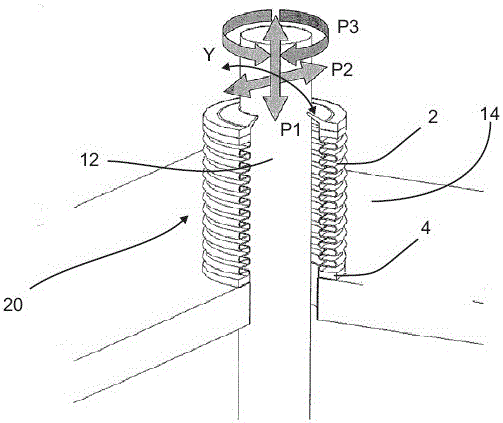

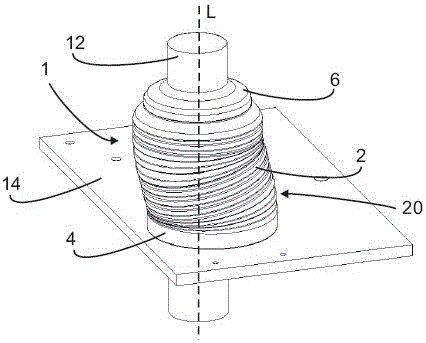

[0067] figure 1 It is a structural schematic diagram of the sealing device 1 . In the embodiment, the second main body 14 or the wall unit 14 is included, and the moving unit 12 that moves relative to the second main body 14 is included. In this case, the middle part between the wall and the moving unit 12 Can be sealed by said sealing device 1 . In this way, it is possible, for example, to create a sterile room below said second body 14 , providing a (non-sterile) environment for the space above second body 14 . Preferably, the body of wall 14 has an opening 15 with a cross section larger than that of the moving unit 12 (such as figure 2 As shown), the motion unit is guided to move through the opening 15 .

[0068] The sealing device 1 comprises a first end portion 4 fixed to the second body 14 . The second end 6 of the sealing device rests against the strip-shaped portion of the movement unit 12 . The reference letter X designates one possible direction of movement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com