Sealing parts

A technology for sealing parts and components, applied in the field of gap rings, which can solve the problems of low operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

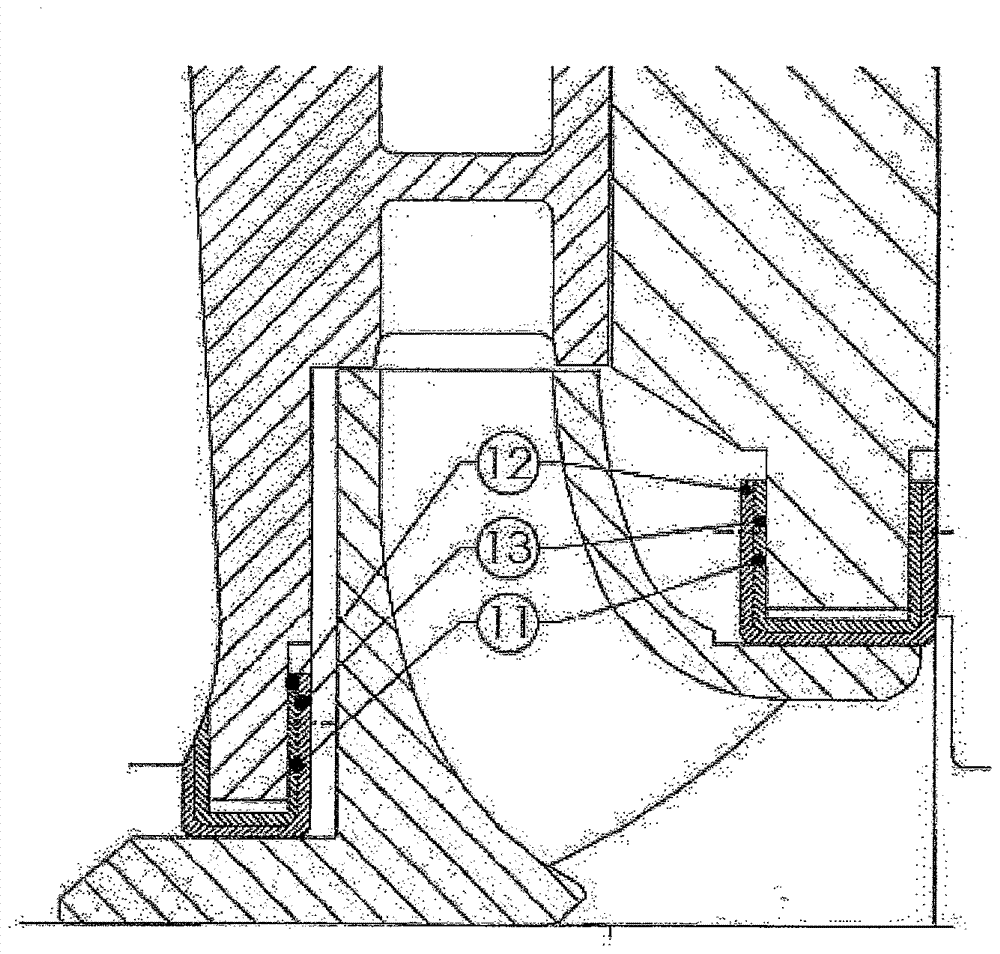

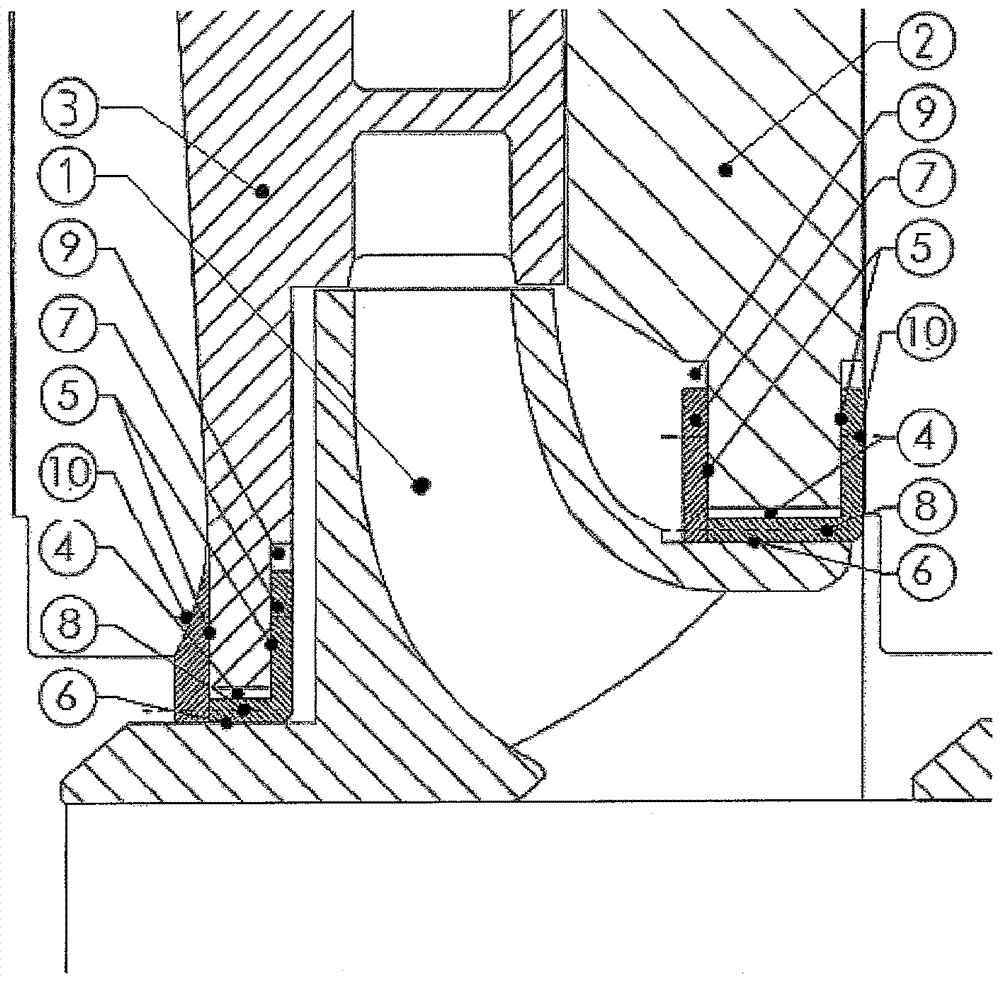

[0020] in figure 1 The first embodiment of the gap ring sealing structure according to the present invention is shown in detail in the example, in which an impeller pump is used in the example. The impeller pump impeller 1 is shown, which in this structure is a rotating rotor part, where it rotates relative to the housing 2 and the guide wheel 3, which are regarded as stators in a fixed position.

[0021] According to the invention, the gap is surrounded by a U-shaped one-piece or multi-piece cylindrical gap ring 7. The slit ring is arranged in the stator composed of the housing 2 and the guide wheel 3 by the slit diameter of the impeller or the impeller pump impeller 1, wherein the slit ring is matched with the U-shaped anti-twist 10 or the inner layer 12 and the outer layer 13 for guidance. Inside the shell.

[0022] The gap ring 7 realizes two radial functional gaps. The gap diameter of the existing radial throttling or impeller pump impeller is used as the gap that always flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com