Vacuum storage cabinet and working method thereof

A storage cabinet and vacuum technology, applied in the direction of packaging under vacuum/special atmosphere, packaging objects under special gas conditions, special packaging objects, etc., can solve problems that cannot meet storage requirements, avoid damage, and ensure storage quality of items Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (Embodiment 1, vacuum storage cabinet)

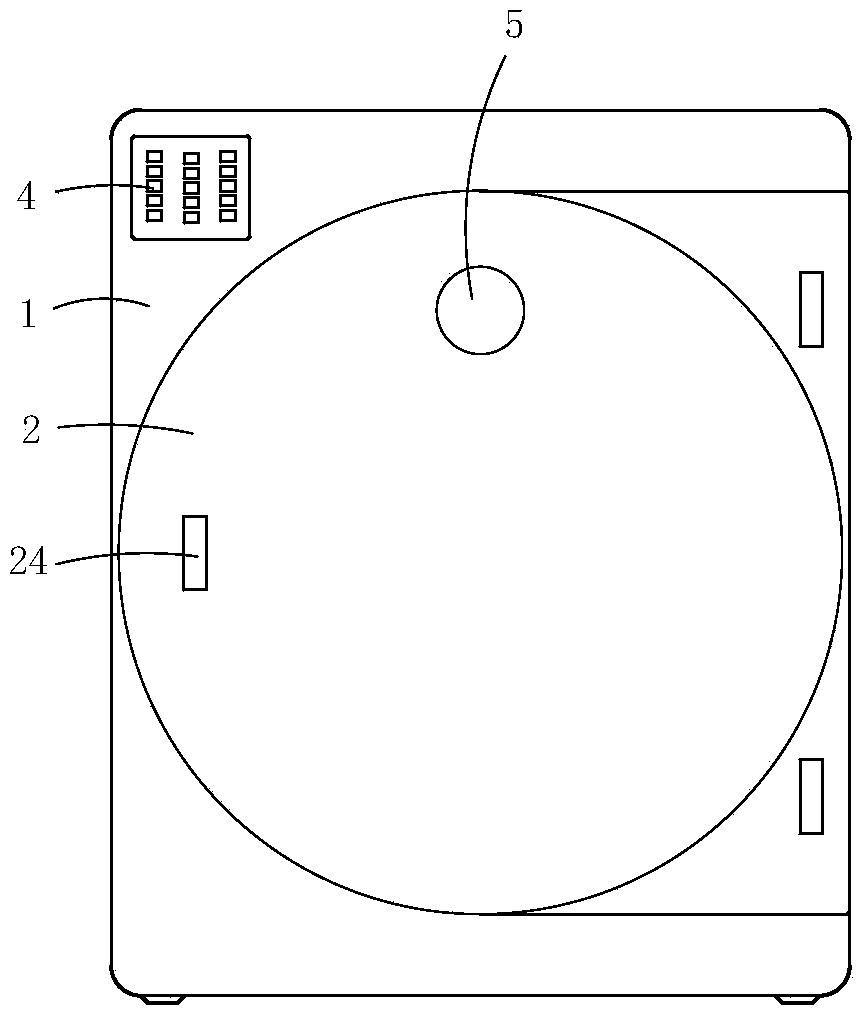

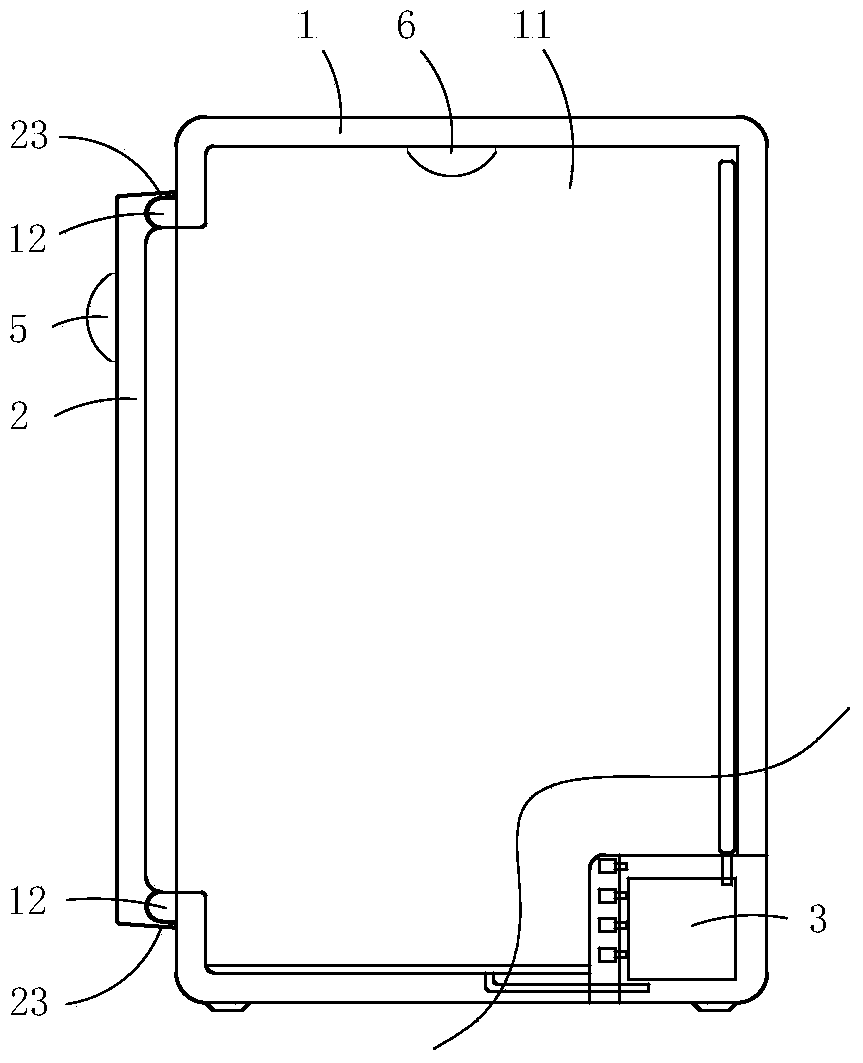

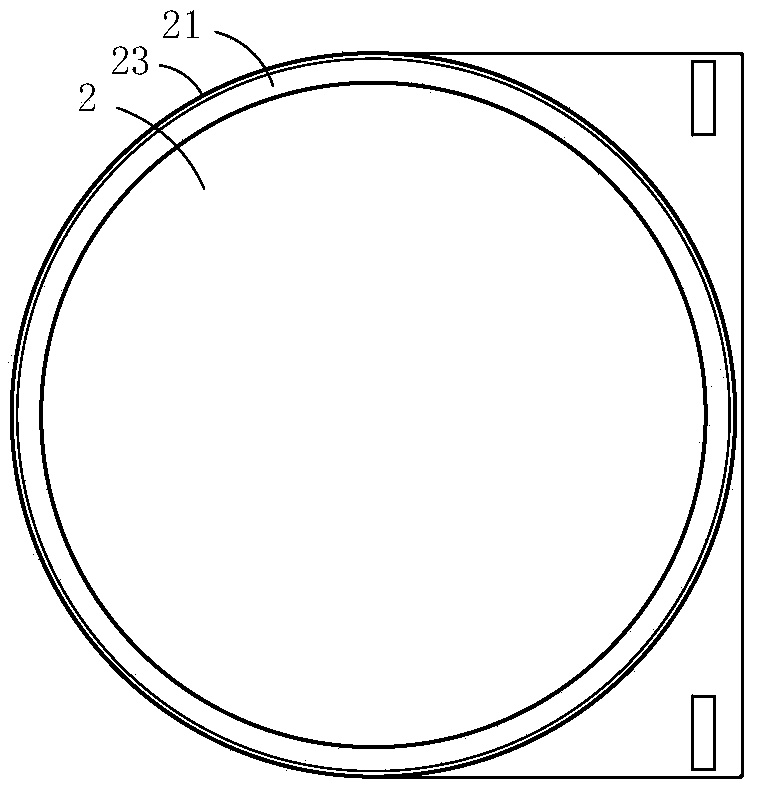

[0020] Figure 1 to Figure 4 A specific embodiment of the invention is shown in which figure 1 It is a schematic diagram of the front view structure of the present invention; figure 2 yes figure 1 A schematic side view of the vacuum storage cabinet shown; image 3 yes figure 1 A rear view structural schematic diagram of the airtight door in the shown vacuum storage cabinet; Figure 4 yes image 3 A side view structural schematic diagram of the airtight door shown.

[0021] Present embodiment is a kind of vacuum storage cabinet, see Figure 1 to Figure 4 As shown, it includes a cabinet body 1 with a storage chamber 11 inside, a hermetic door 2 for sealing the opening of the storage chamber, and a vacuum device 3 for extracting the air in the storage chamber.

[0022] The vacuuming device includes a vacuum pump arranged at the bottom of the cabinet, an air suction port arranged in the storage chamber, a pressure sensor...

Embodiment 2

[0028] (embodiment 2, working method)

[0029] This embodiment is the working method of the above-mentioned embodiment 1, including the following workflow:

[0030] ① The vacuum device is automatically activated and deactivated according to the real-time data detected by the pressure sensor in the storage chamber and the preset pressure data; the first camera is always on, and when foreign objects enter the shooting range of the first camera, it will cause The image data captured by the first camera changes. After the intelligent central controller confirms that the first camera is in working condition and the image data has changed, it first starts the second camera to capture the video image of the space environment where the vacuum storage cabinet is located. If the second camera is normal open, then enter the next workflow; if the second camera cannot be started, the intelligent central controller determines that it is an alert level, stops entering the next workflow, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com