Lip seal anti-water structure roller

A lip-seal, water-proof technology, applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems of national economic loss, reduced service life, affecting the service life of idlers, etc., to solve the problems of waterproof, contact Low frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

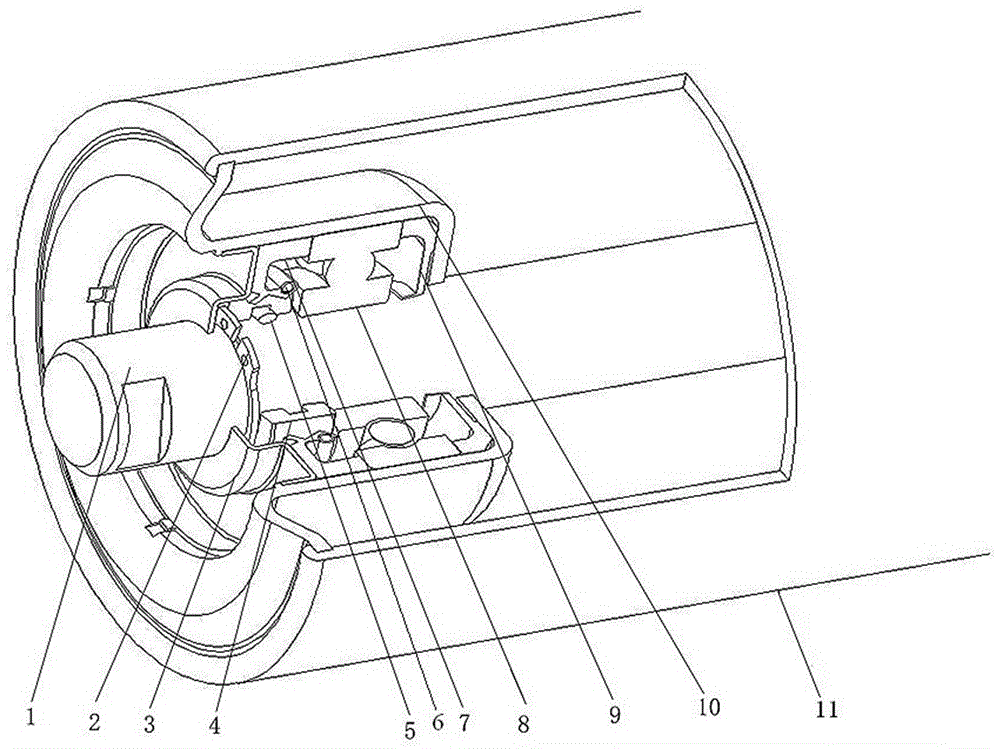

[0010] An idler roller with a lip-type seal water ingress prevention structure, including an idler shaft 1 installed with an idler roller body 11, a bearing assembly installed in a bearing housing 10, and the bearing assembly in the bearing housing 10 is provided with an inner seal 9 , idler bearing 8, lip seal 7, O-shaped spring 6, mirror wear-resistant sleeve 4, O-shaped seal ring 5 is installed on the inner surface of mirror wear-resistant sleeve 4, and the left side of mirror wear-resistant sleeve 4 is installed with shaft elastic Circlip 2, iron cover 3 is installed on the left side of circlip 2 for the shaft.

[0011] The idler shaft 1 is closely combined with the inner hole surface of the mirror wear-resistant sleeve 4, and the inner hole surface of the mirror wear-resistant sleeve 4 is provided with a groove, and an O-shaped sealing ring 5 is installed in the groove; the mirror surface of the outer cylindrical surface of the mirror wear-resistant sleeve 4 A lip seal 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com