Oil vapor recovery atomizer

An atomizer, oil and gas technology, applied in special distribution devices, packaging, distribution devices, etc., to increase the effect of oil and gas recovery and prevent the effect of life reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

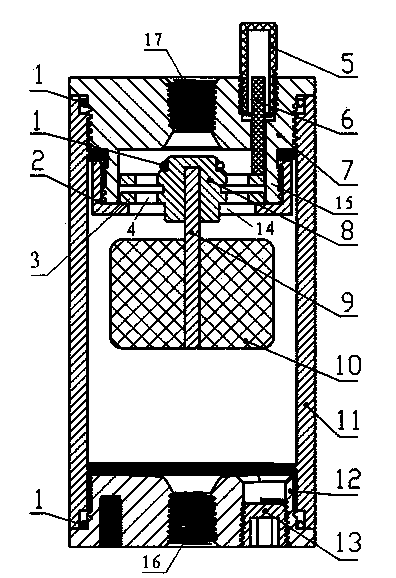

[0018] Embodiment one: if figure 1 As shown, an atomizer for oil and gas recovery includes an atomizer body 11, the upper and lower ends of the atomizer body 11 are respectively provided with an upper end cap 7 and a lower end cap 12, and the upper end cap 7 and the lower end cap 12 are connected to the A sealing ring 1 is provided between the atomizer bodies 11, and an oil and gas outlet 17 communicating with the interior of the atomizer body 11 is provided on the upper end cap 7, and the interior of the atomizer body 11 is close to the upper end cap 7, a valve cavity corresponding to the oil and gas outlet 17 is provided, and a valve core 8 corresponding to the oil and gas outlet 17 is arranged in the valve cavity, and the side wall of the valve core 8 is provided with a valve cavity matching the above valve cavity, and The valve plate 3 that can slide up and down in the valve cavity, the valve plate 3 is provided with a plurality of oil and gas through holes 4, and the bott...

Embodiment 2

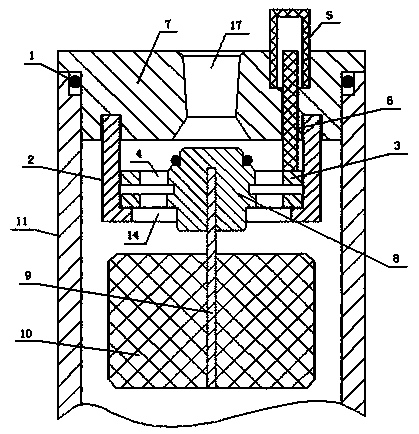

[0024] Embodiment two: if figure 2 As shown, the lower end surface of the upper end cover 7 is provided with a thread groove, the valve cavity is formed by the valve core end cover 2 threaded on the thread groove, and the valve hole 14 is directly arranged at the valve core end On the cover 2, the rest of the structure of this embodiment is the same as that of Embodiment 1.

[0025] The valve cavity of the present invention can be realized through various structures and combinations, as long as it can complete the required functions, it is not limited to the structures disclosed in the above embodiments, such as the valve cavity can also be integrally formed on the upper end The lower end surface of the cover 7 or the valve core end cover 2 of the inner wall of the atomizer body 11 is formed, and the valve hole 14 is directly arranged on the valve core end cover 2 .

[0026] The present invention can not only atomize a small amount of oil that enters the atomizer, but recycl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com