Catalytic combustion treatment device and treatment method for organic waste gases

A catalytic combustion and organic waste gas technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of affecting the service life of the catalyst, troublesome manufacturing and processing, and increasing investment costs, so as to improve the comprehensive utilization effect and avoid life reduction. The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

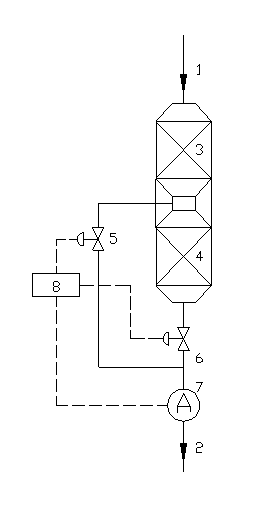

[0019] Such as figure 1 As shown, the organic waste gas catalytic combustion treatment device of the present invention is composed of two catalyst beds A and B connected in series, regulating valves A and B, control system 8, waste gas online analysis equipment 7 and connecting pipelines. When the concentration of the target gas in the exhaust gas entering the device or the amount of treated gas is low, the concentration of the target gas in the main exhaust pipeline 2 is at a low level due to sufficient reaction, that is, it is below the set value. At this time, the control system opens the regulating valve 5 , while closing the regulating valve 6, only the catalyst bed A participates in the catalytic combustion reaction of the exhaust gas; when the concentration of the target gas in the intake line increases or the amount of exhaust gas increases, the reaction of the exhaust gas in the catalyst bed A is insufficient, resulting in the main The concentration of the target gas...

Embodiment

[0022] The organic waste gas discharged from the grease trap, flotation tank and oily sewage tank of a sewage treatment plant is treated by a catalytic combustion device. Under normal operating conditions, the concentration of non-methane total hydrocarbons in the exhaust gas discharged from grease traps, flotation tanks and oily sewage tanks is 2000-5000mg / Nm 3 , but during the large breathing period of the oily sewage tank, the concentration of non-methane total hydrocarbons in the mixed exhaust gas is 4000-8000mg / Nm 3 . Main operating conditions: The whole device is composed of two catalyst beds. Under normal operating conditions, the exhaust gas passes through one bed. During the large breathing period of the oily sewage tank, the exhaust gas passes through the two catalyst beds. The temperature of the exhaust gas entering the catalyst bed is 350°C. Reaction space velocity 8000h -1 .

[0023] After treatment, the concentration of non-methane total hydrocarbons in the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com