Buckling-restrained bracing for misaligned cross-plates

A buckling restraint and cross-slab technology, applied in building components, earthquake-proof and other directions, can solve the problems of reducing the buckling restraint support performance, single variety of isolation materials, difficult concrete construction, etc., to simplify the processing difficulty, reduce the cost, and avoid conflicts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

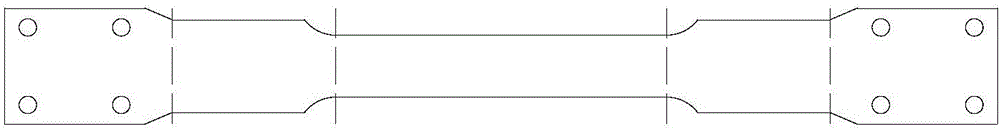

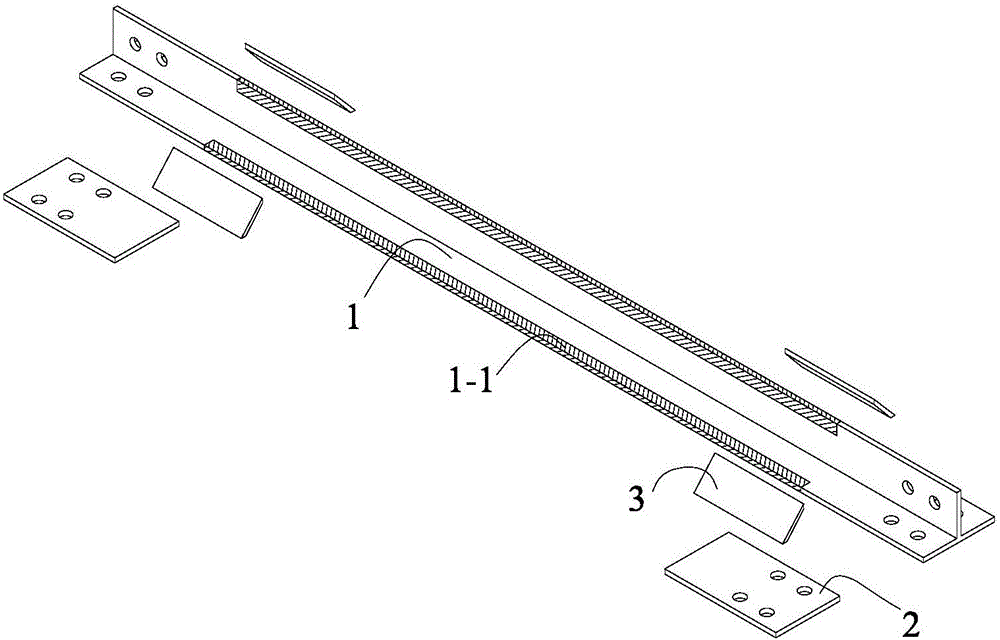

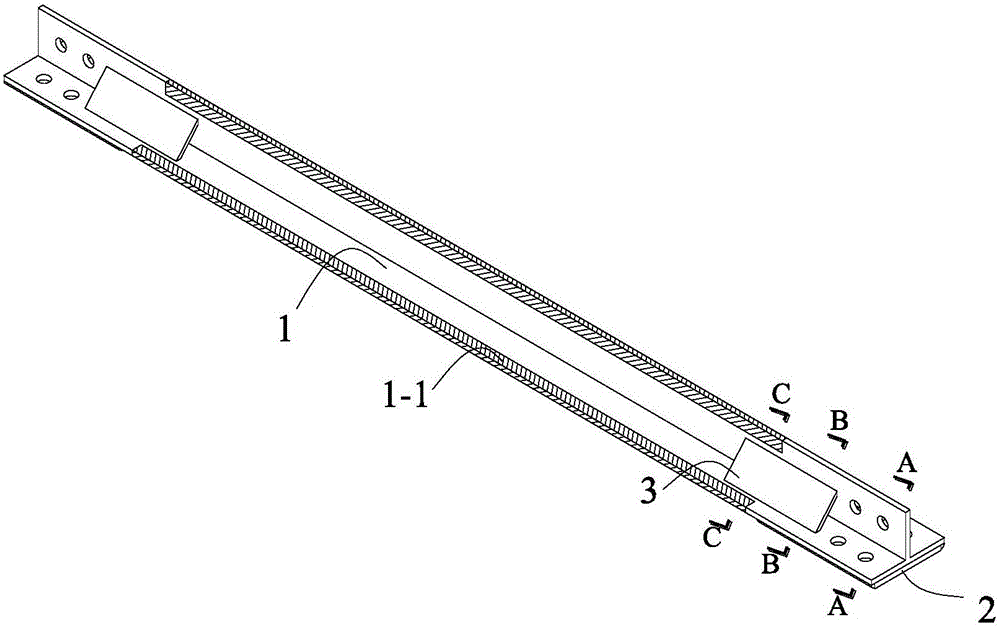

[0047] Such as Figure 2-10 Shown: a buckling-constrained brace of a misplaced cross plate, including an energy-dissipating inner core member 1, a first group of reinforcement plates 2, a second group of reinforcement plates 3, and a buckling restraint component 4 of equal cross-section; the first group of reinforcement plates 2 is welded At the two ends of the energy dissipation core member 1, the second set of reinforcement plates 3 are welded to the flange or web of the energy dissipation inner core member 1 near the root 1 / 2, and the solid along the length direction of the energy dissipation core member 1 The connection point is located inside the first group of reinforcement plates 2, and the end point is located inside the constant-section buckling restraint component 4, and the first group of reinforcement plates 2 and the second group of reinforcement plates 3 are welded to different positions of the cross-section of the energy-dissipating inner core member 1, Partial in...

Embodiment 2

[0049] Such as Figures 11-16 As shown: this embodiment is the same as the rest of embodiment 1, the difference is that the energy-dissipating inner core board 1 is an I-shaped section, and the specific fixed position of the second group of reinforcement boards 3 is changed.

Embodiment 3

[0051] Such as Figure 17 Shown: this embodiment is the same as the rest of embodiment 1, the difference is that the second set of reinforcing plates 3 is angle steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com