Brake shoe

A brake shoe and shoe technology, applied in the field of brake shoes, can solve the problems of frequent replacement of friction linings, small wear limit range, potential safety hazards, etc. Promote high-value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

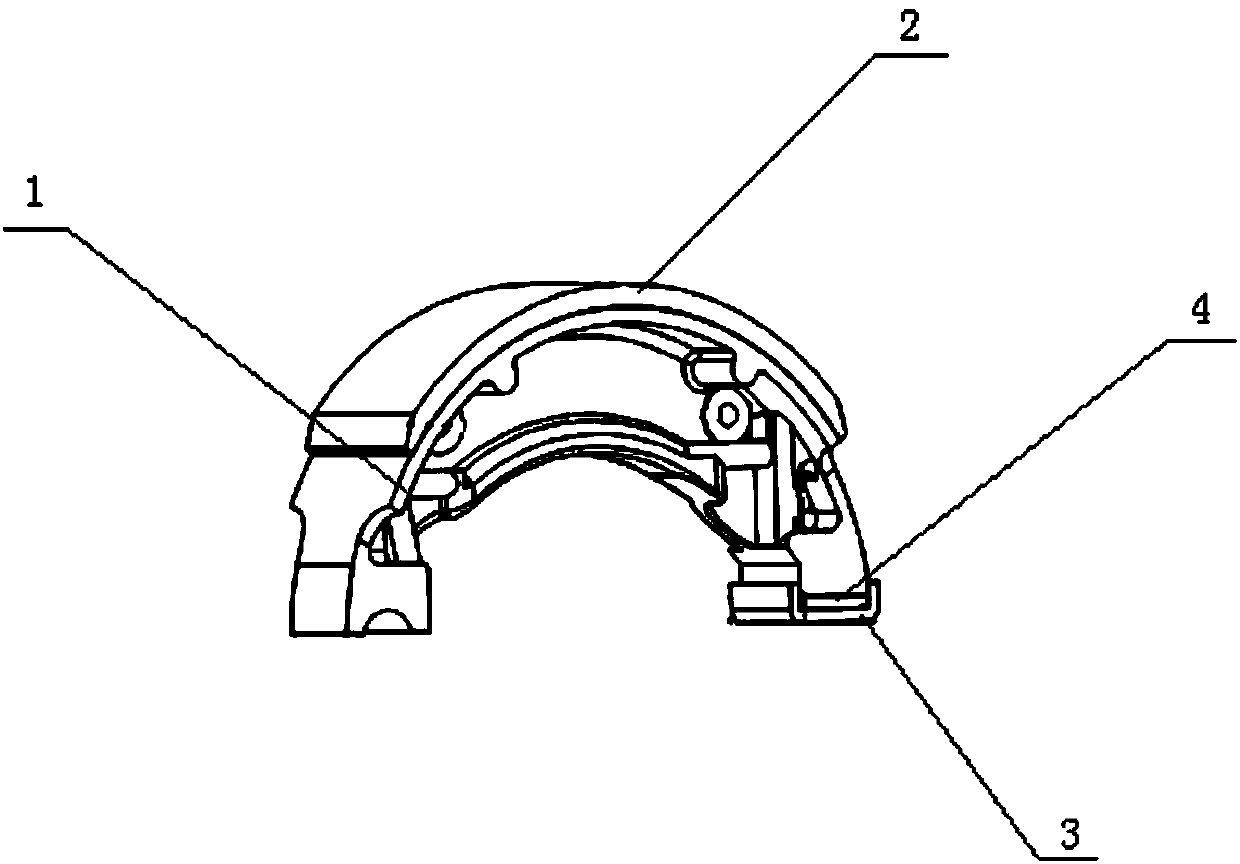

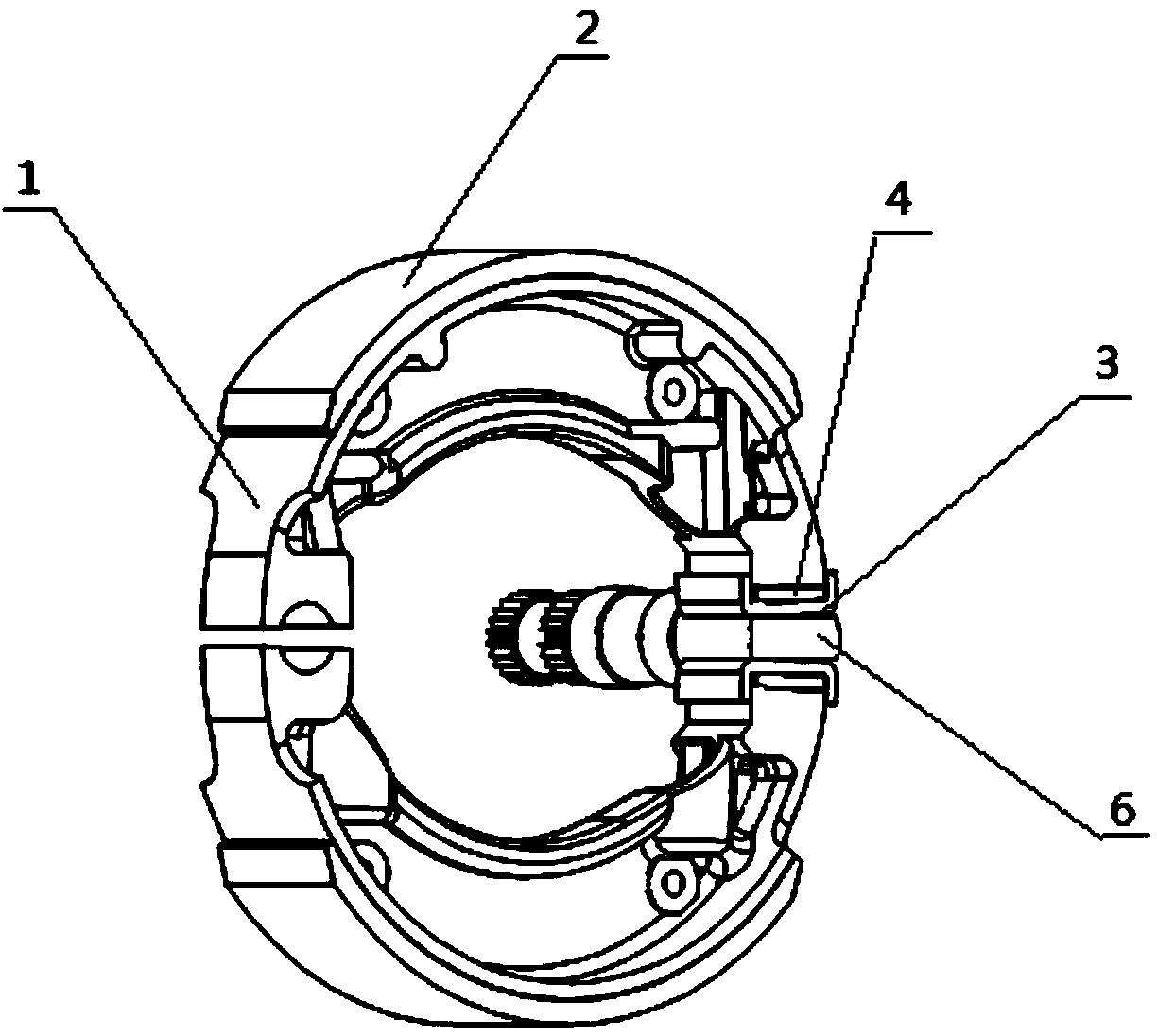

[0031] Such as figure 1 or figure 2 As shown, a brake shoe includes: a shoe 1, a friction lining 2, a transition block 3, and a compensation pad 4, wherein: the shoe 1 consists of a circular arc-shaped skeleton and faces from the concave arc of the skeleton The support part extending at the center is integrally formed. One end of the shoe iron 1 is a hinged end with a semicircular groove on its end surface, and the other end is a free end with a flat end surface. The four sides of the free end are flat and perpendicular to the end surface; friction; The lining 2 is in the shape of a circular arc sheet corresponding to the convex arc surface of the frame of the shoe iron 1 and is correspondingly arranged on the convex arc surface of the frame of the shoe iron 1. One end of the transition block 3 is provided with a groove and the end surface of the other end is flat, which is U-shaped, and the bottom of the groove is a flat plane. The size of the groove corresponds to the size of...

Embodiment 2

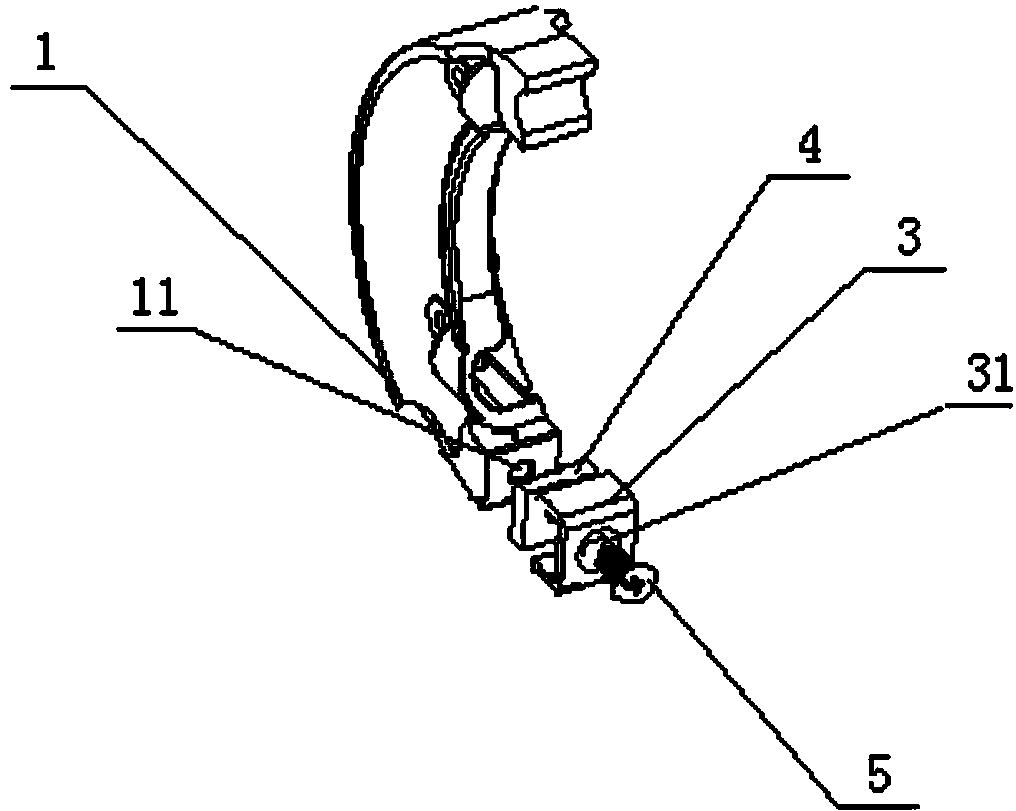

[0034] Like the present invention of embodiment 1, it can be reworked and the original brake shoe can be improved, that is, in order to adapt to the small changes of the present invention, the free end of the shoe 1 of the original brake shoe The small plane adopts a height suitable for the present invention. Correspondingly, a screw hole 11 is machined on the small plane, and the transition block 3 and the compensation washer 2 can be installed on the shoe with the countersunk screw 5, without changing The overall structure of the original brake device. When the brake drum has a certain amount of wear, the arc surface of the friction part of the brake drum by the friction lining 2 will be dented due to wear, but the arc surface that is not rubbed by the friction lining 2 will remain unchanged, so the arc of the brake drum Steps will appear on the surface. When the brake shoe of the present invention is installed, it may interfere with the steps of the brake drum. The method of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com