Non-erosive flow-limiting valve used for sealing surface of glue gun

A technology of sealing surface and gluing gun, applied in the field of restrictor valve, can solve the problems of shortening valve life and accelerating valve wear, etc., and achieve the effect of prolonging service life, convenient processing and good current restricting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

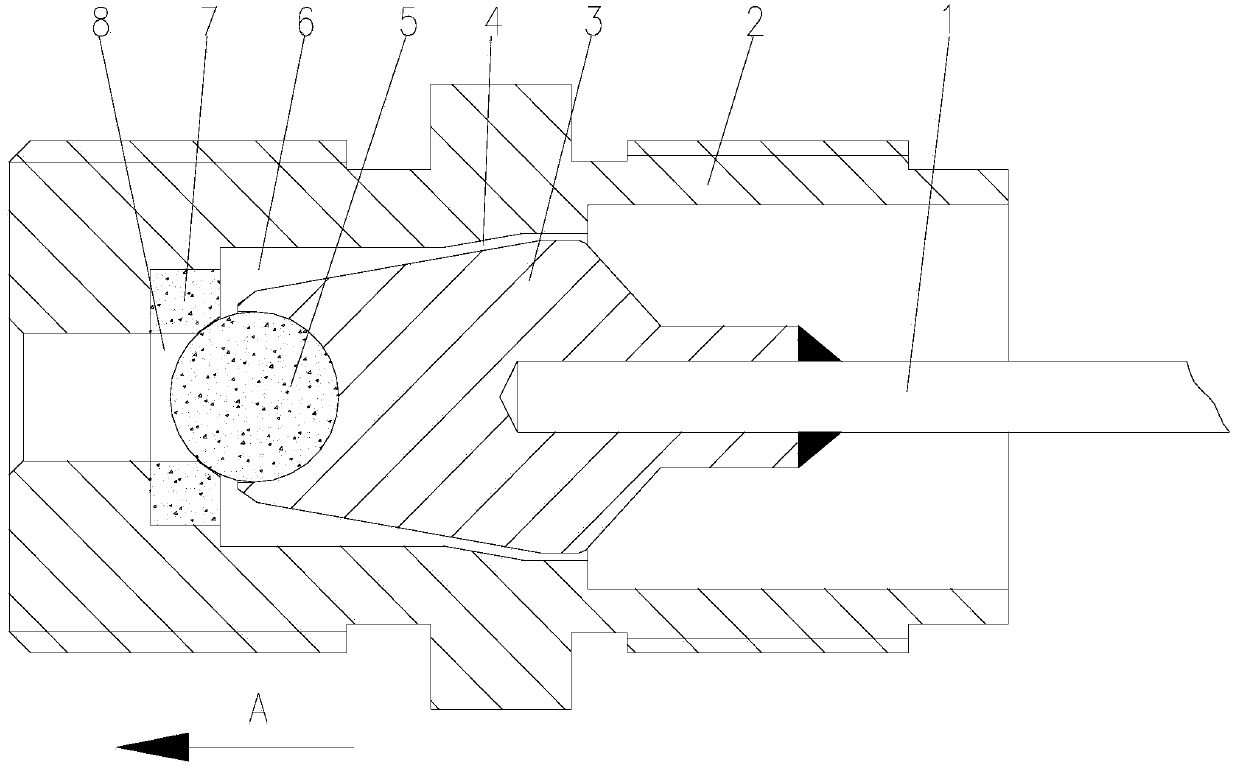

[0016] figure 1 It is a schematic diagram of the structure of the present invention. As shown in the figure, the present invention provides a non-erosion restrictor valve for the sealing surface of a glue gun, which includes a valve seat 2 and a valve core arranged in the valve seat 2 3 and the valve core 3 can reciprocate along the axial direction of the valve seat 2. The reciprocating motion of the valve core 3 is driven by the coaxially fixed valve stem 7 of the valve core 3, and the outer diameter of the valve core 3 is smaller than The inner diameter of the valve seat 2 cooperates with the inner side wall of the middle part of the valve seat 2 to form a restrictive channel 4 for buffering the glue. The restrictive valve for the sealing surface of the glue gun of the present invention is not eroded, Through the restricting channel, the high-pressure glue is buffered in the inner middle of the valve seat, which can effectively prevent the high-pressure glue from directly ero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com