Top-mounted ball valve

A top-mounted, ball valve technology, applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of short life, poor sealing reliability, etc., and achieve the effect of prolonging service life and two-way reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

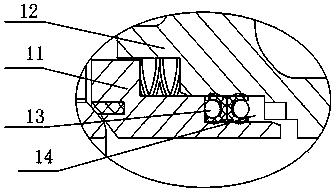

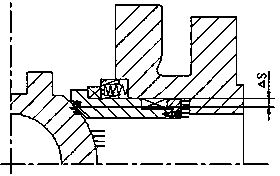

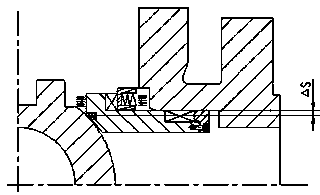

[0032] Such as Figure 4-Figure 6 Shown is a top-mounted ball valve of the present invention, which includes a valve seat 3 located between a ball 1 and a valve body 2. The valve seat 3 and the ball 1 are sealedly connected by a sealing material 4, and the valve seat 3 and the valve body 2 are sealed by a sealing element 5 Sealed connection, further comprising a spring assembly 6 located between the valve body 2 and the valve seat 3. One end of the spring assembly 6 abuts on the valve body 2. A first step 21 is formed on the valve body 2, and the seal 5 is located at the In the sealing gap formed by the shoulder 211 of a step 21 and the radial end surface of the spring assembly 6, one end of the seal 5 abuts against the shoulder 211 of the first step 21, and the other end abuts against the radial direction of the spring assembly 6. End surface; the outer circumferential surface of the valve seat 3 is provided with a limiting member 7, and the radial end surface of the limiting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com