Parallel projection method and parallel projection device for detecting diameter and thickness of blank cake

A technology of thickness detection and parallel projection, applied in measuring devices, optical devices, instruments, etc., can solve the problems of low accuracy and low efficiency, and achieve the effect of high accuracy, high efficiency and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

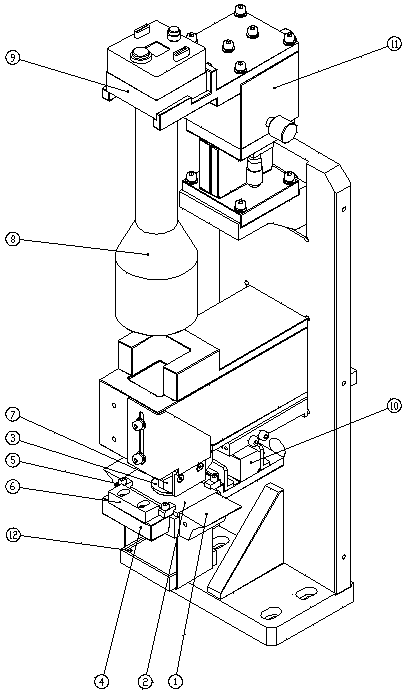

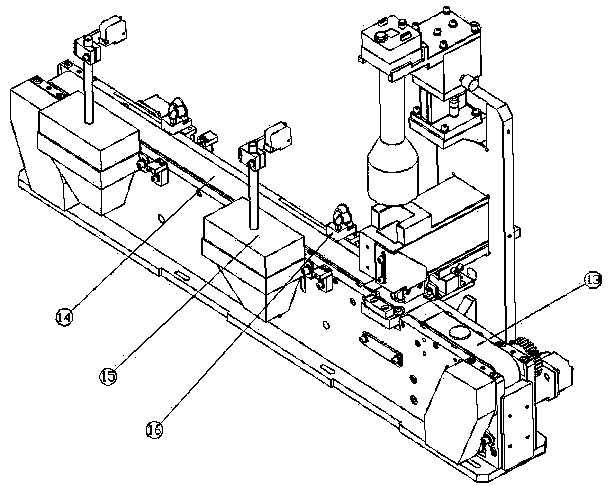

[0014] Such as Figure 1-2 As shown, the present invention includes a transmission unit, a detection unit, and a rejection unit composed of an air blowing block 16 and a coin bucket 15 .

[0015] The conveying unit includes a front conveying flat belt 13 and a rear conveying flat belt 14, both run in the same direction, and the detection unit is located between them.

[0016] The detection unit includes an optical glass 2, a glass platform 1, and a platform fixing frame 4 stacked sequentially from top to bottom. After the cake 3 is transferred to the optical glass 2 by the front conveying flat belt 13, it slides over the optical glass 2 under the action of inertia and then enters the rear conveying flat belt 14 to continue conveying; the optical glass 2 is fixed on the glass platform 1 by the optical glass fixing block 5 Above, the bottom of the optical glass 2 is provided with a bottom light source 12, an optical lens 8 and a camera 9 are arranged directly above, the optical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com