A kind of control method of maglev centrifuge and maglev system

A control method and magnetic levitation technology, applied in centrifuges, holding devices using magnetic attraction or thrust, electrical components, etc., can solve the problems of road subsidence, lack of ribs on the pipe body, and high noise, saving lubricating oil and maintaining gas. Clearance distance, the effect of eliminating mechanical fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

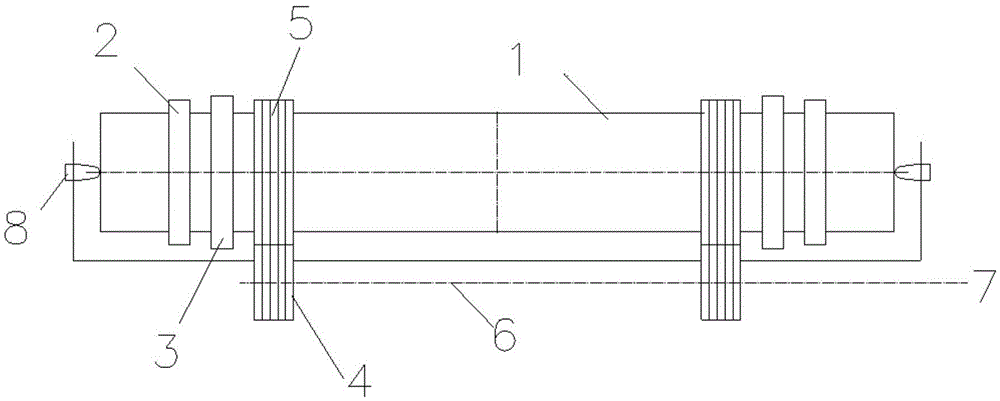

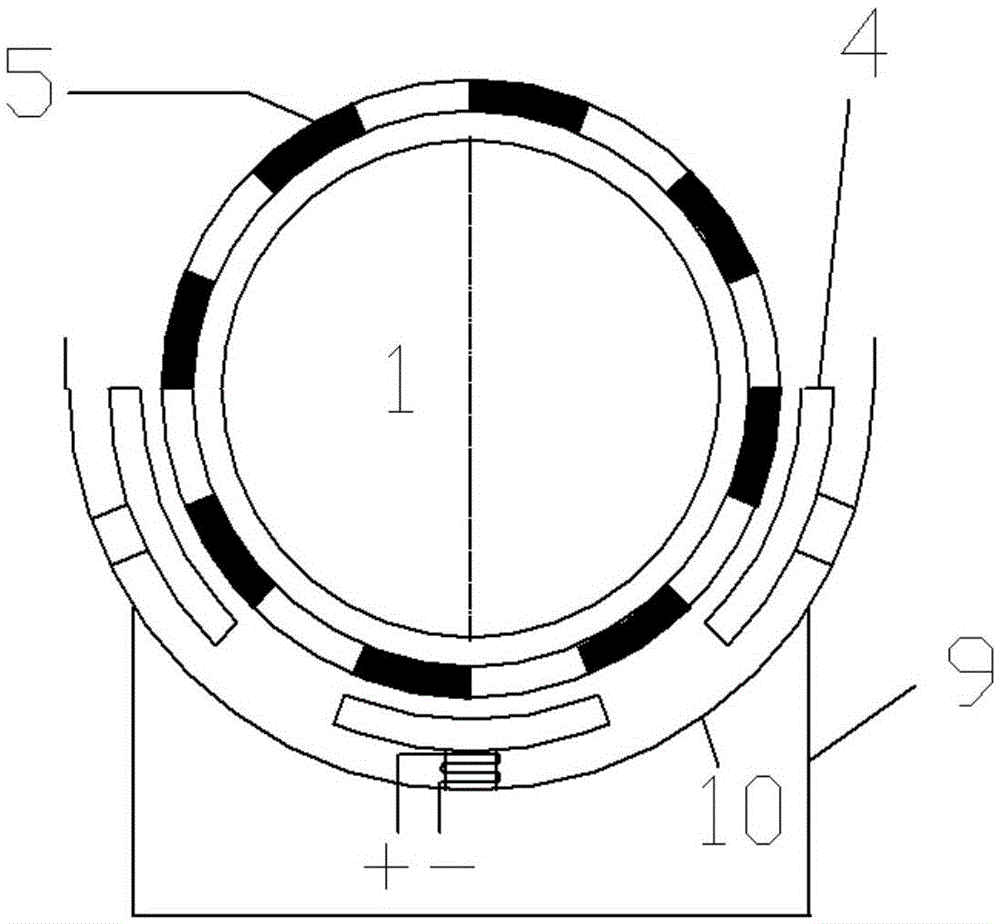

[0034] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

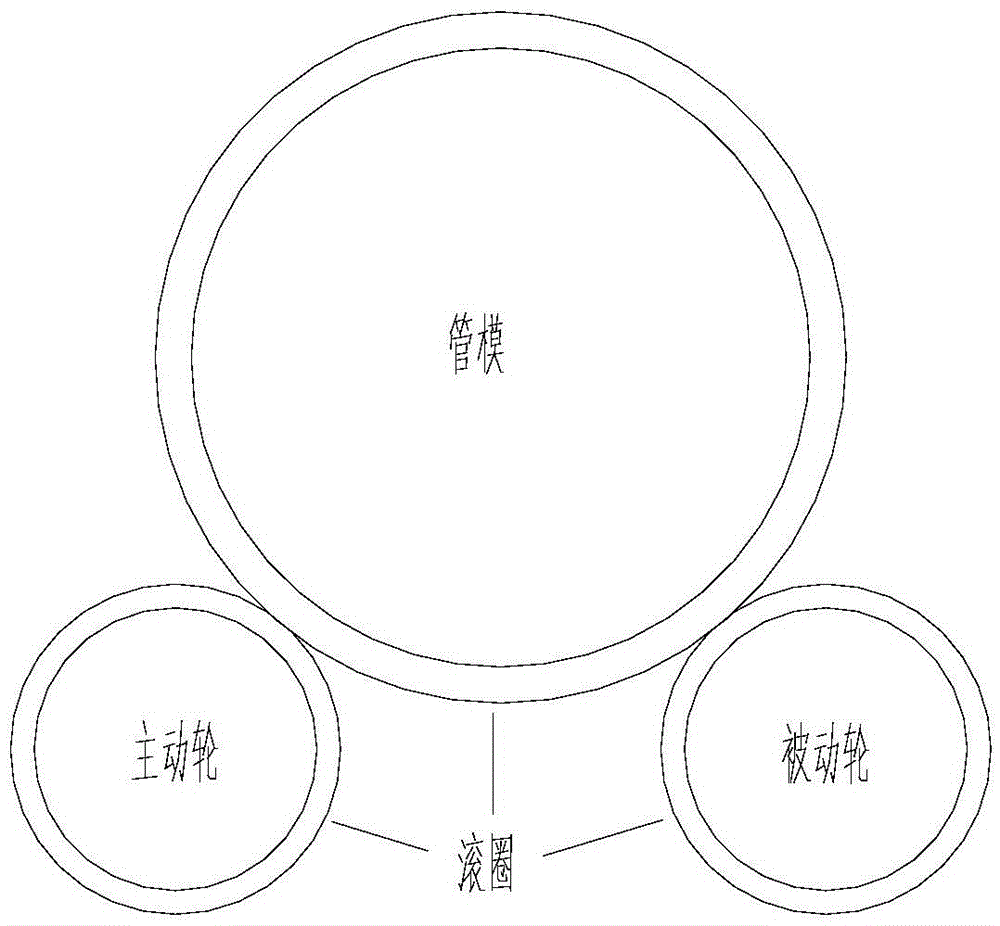

[0035] According to purpose of the present invention, to solve the above problems that the centrifuge exists, the best way is to allow the pipe mold not to contact the supporting roller. As long as there is no contact, problems such as wear, noise, and mode hopping will be solved, and the power consumed by the equipment will be greatly reduced. In this regard, the most preferred method is "maglev", which is a new technology developed in recent decades, especially the emergence of maglev trains has greatly promoted the application of maglev technology. The principle is very simple, that is, magnets of opposite sex attract and same sex repel each other. However, it is not an easy task to make a certain device suspend and work stably according to the design requirements (such as rotation or translation), and it involve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com