A receiver with an improved driving structure

A technology of driving structure and receiver, applied in the field of receiver, can solve the problems of E-shaped armature limited structure, large receiver width, affecting stability, etc., and achieve the effect of expanding the application range, reducing the overall volume and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

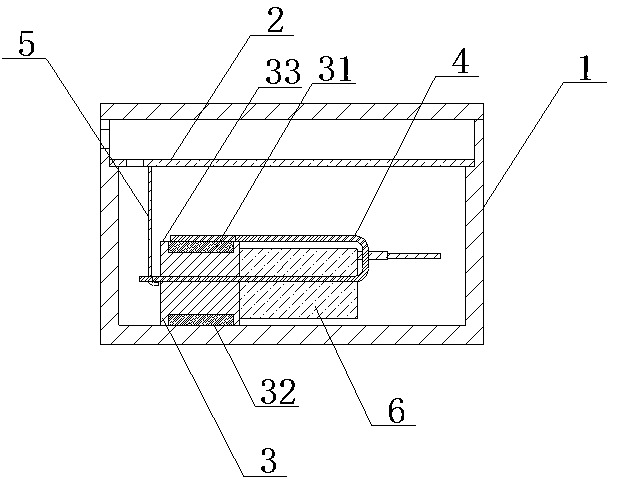

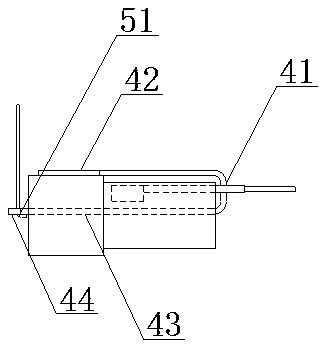

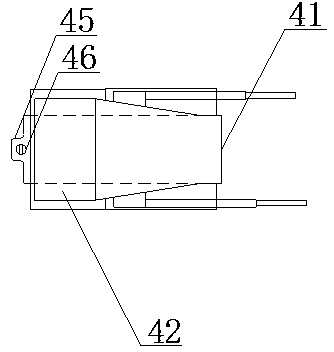

[0026] Such as Figure 1-5 As shown, in the first embodiment of the receiver with the improved driving structure involved in the present invention, it includes the casing 1 and the diaphragm 2, and also includes: the iron core 3, the lower end surface 32 of which is welded or bonded The entire surface is fixedly connected to the inner wall of the housing 1, and the through hole of the iron core 3 is covered with a magnet 31; the side of the armature 4 is U-shaped, starting from the bending part 41, and one end of the armature 4 faces The front extends to the upper end surface 33 of the iron core 3 and forms a first connection surface 42 there. The first connection surface 42 and the upper end surface 33 are fixedly connected to the entire surface by welding or bonding. The other end of the armature 4 As the vibrating part 43 extends forward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com