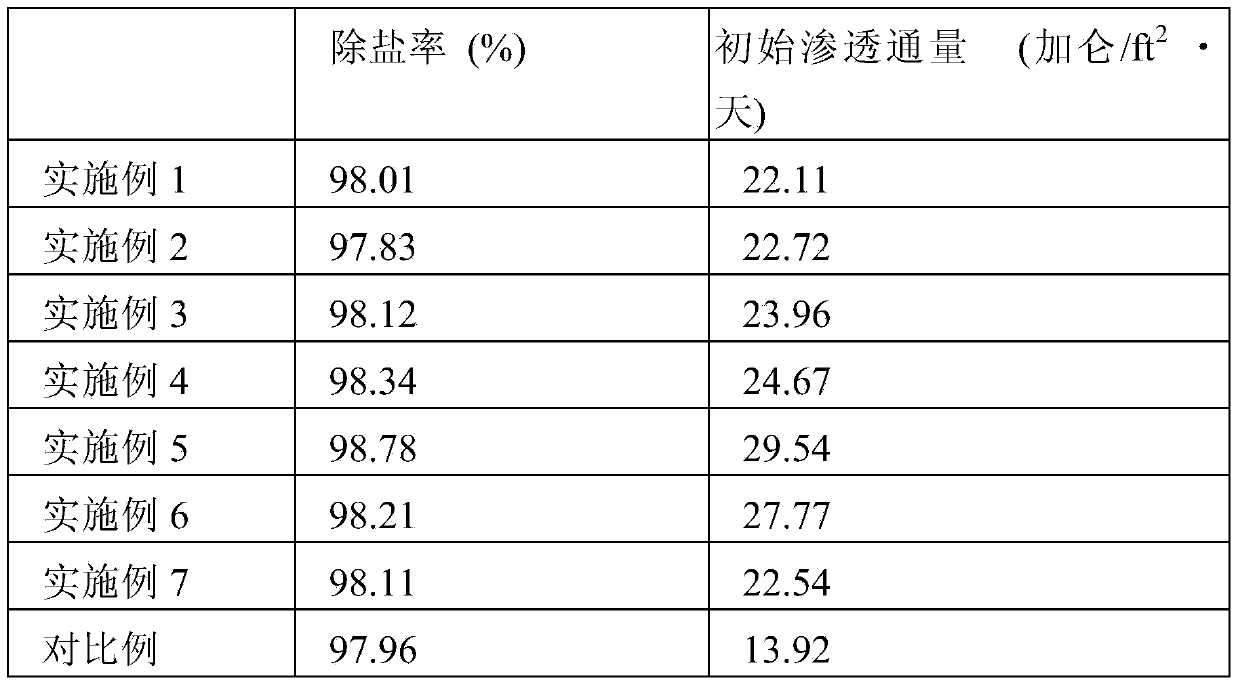

Polyamide-based reverse osmosis membrane having excellent initial permeate flow rate and method for manufacturing same

A technology of reverse osmosis membrane and polyamide, applied in the direction of reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of low yield and low initial permeation flux efficiency of reverse osmosis membrane, and achieve high initial The effect of osmotic flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the reverse osmosis membrane according to the present invention may include: forming a polysulfone layer on the surface of the porous support and forming a polyamide active layer on the porous support.

[0035] The formation of the polysulfone layer on the surface of the porous support can be carried out by methods known in the art, for example, it can be carried out by casting polysulfone on a non-woven fabric formed of polyester material, but there is no specific limitation thereto . In this case, in order to cast polysulfone, when polysulfone solid is added to N,N-dimethylformamide (DMF) aqueous solution and dissolved therein at 80°C for 12 hours or more to obtain uniform The homogeneous liquid phase was poured on the nonwoven fabric to cast polysulfone.

[0036] Meanwhile, the forming of the polyamide active layer on the porous support may include: contacting the aqueous solution containing the amine compound with the porous support on whi...

Embodiment 1

[0045] 18% by weight of polysulfone solid was added to an N,N-dimethylformamide (DMF) solution, and dissolved therein at a temperature of 80° C. for 12 hours or more to obtain a uniform liquid phase. A solution having a uniform liquid phase was casted at a thickness of 140 to 150 μm on a nonwoven fabric formed of a polyester material and having a thickness of 95 to 100 μm, thereby forming a porous polysulfone support.

[0046] After the porous polysulfone support prepared by this method was immersed in and removed from an aqueous solution containing 2% by weight m-phenylenediamine (mPD) for 2 minutes, the excess aqueous solution was removed using a roller under a pressure of 25 psi, and then the The porous polysulfone support was dried for 1 minute.

[0047] Next, after immersing the support in an organic solution containing 0.01% by weight of benzoyl chloride and 0.1% by weight of trimesoyl chloride (TMC) and having an ISOL-C (SK chemical) solvent for 1 minute and removing th...

Embodiment 2

[0049] Except that the content of benzoyl chloride was 0.02% by weight, a reverse osmosis membrane was prepared using the same procedure as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com