Rice straw strip-tilling and returning and wheat drill seeding combined machine

A rice straw and working machine technology, applied in the field of compound working machines, can solve the problems of wasting tractor fuel, unfavorable crop growth, power loss, etc., and achieve the effects of saving fuel, reducing ground breaking area, and small power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

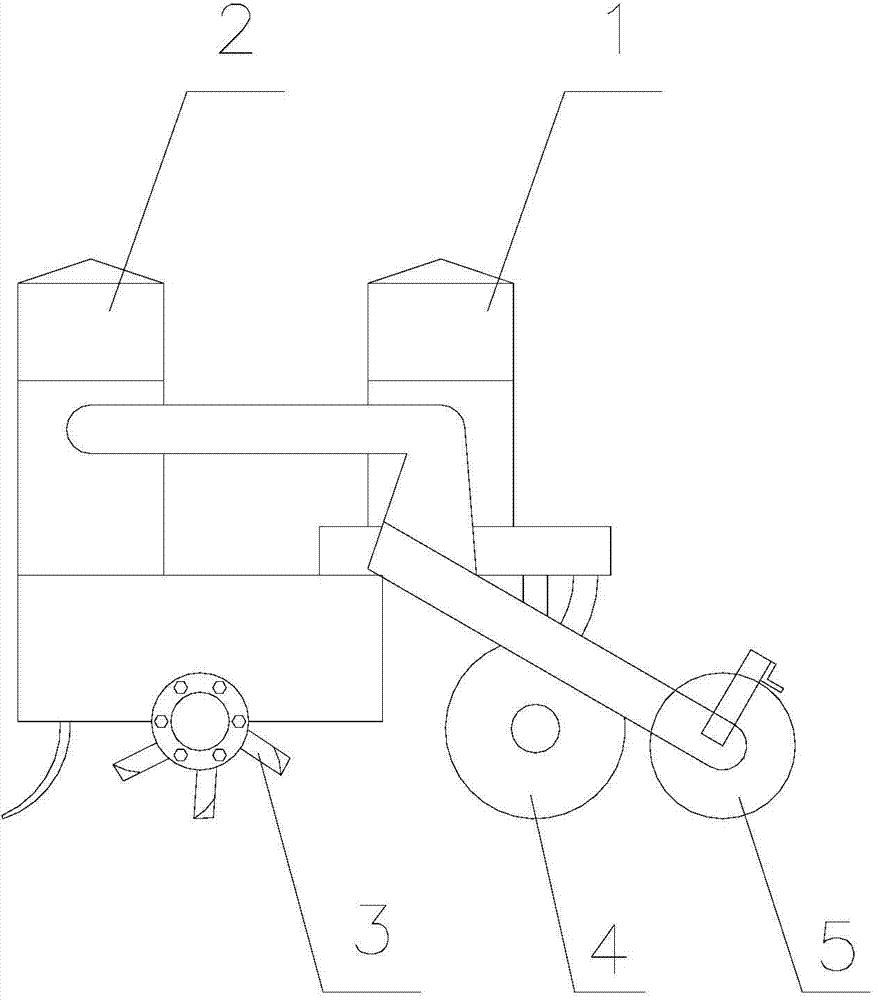

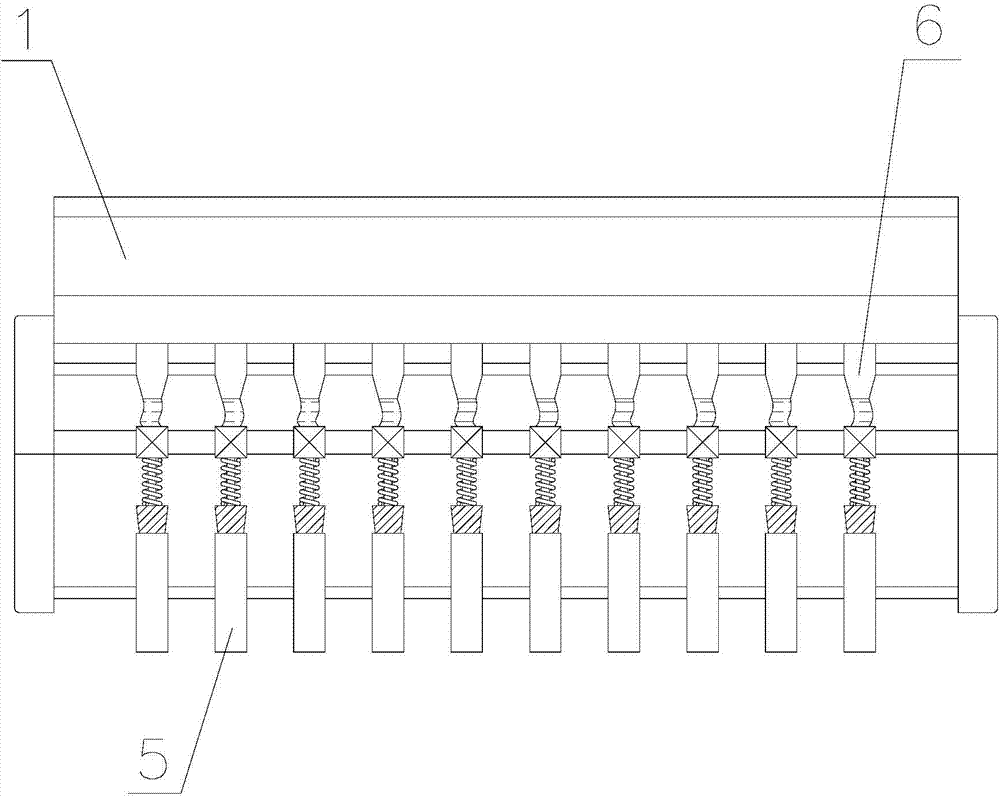

[0018] Such as figure 1 with figure 2 As shown in the figure, the rice straw belt plowing integrated wheat drilling compound operation machine includes a frame, a seeding box 1, a fertilization box 2, a seeder 4, and a pressure roller 5. The frame is equipped with a coupling for receiving the input power of the tractor. , a gearbox and a cutter shaft, the coupling is connected with the cutter shaft through a gearbox, the cutter shaft is provided with a tiller 3, the fertilization box 2 is arranged above the tiller 3, and the seeding box 1 is connected to the sowing Connected to the seeder 4, the pressure roller 5 is arranged on the rear side of the seeder 4 and is connected and fixed with the frame, and several combined tiller blades 3 are arranged side by side on the cutter shaft, and at least one tiller blade is separated between adjacent tiller blades 3 The distance of the installation position; the pressing roller 5 is composed of a roller shaft and a plurality of roller...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap