Glue coating method and device for medical plastic needle filter cover

A technology of gluing device and filter cover, which is applied to devices and coatings that apply liquid to the surface, can solve the problems of ineffectiveness of the filter membrane, excessive adhesion of glue, and easy flow of glue into the filter membrane, etc. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

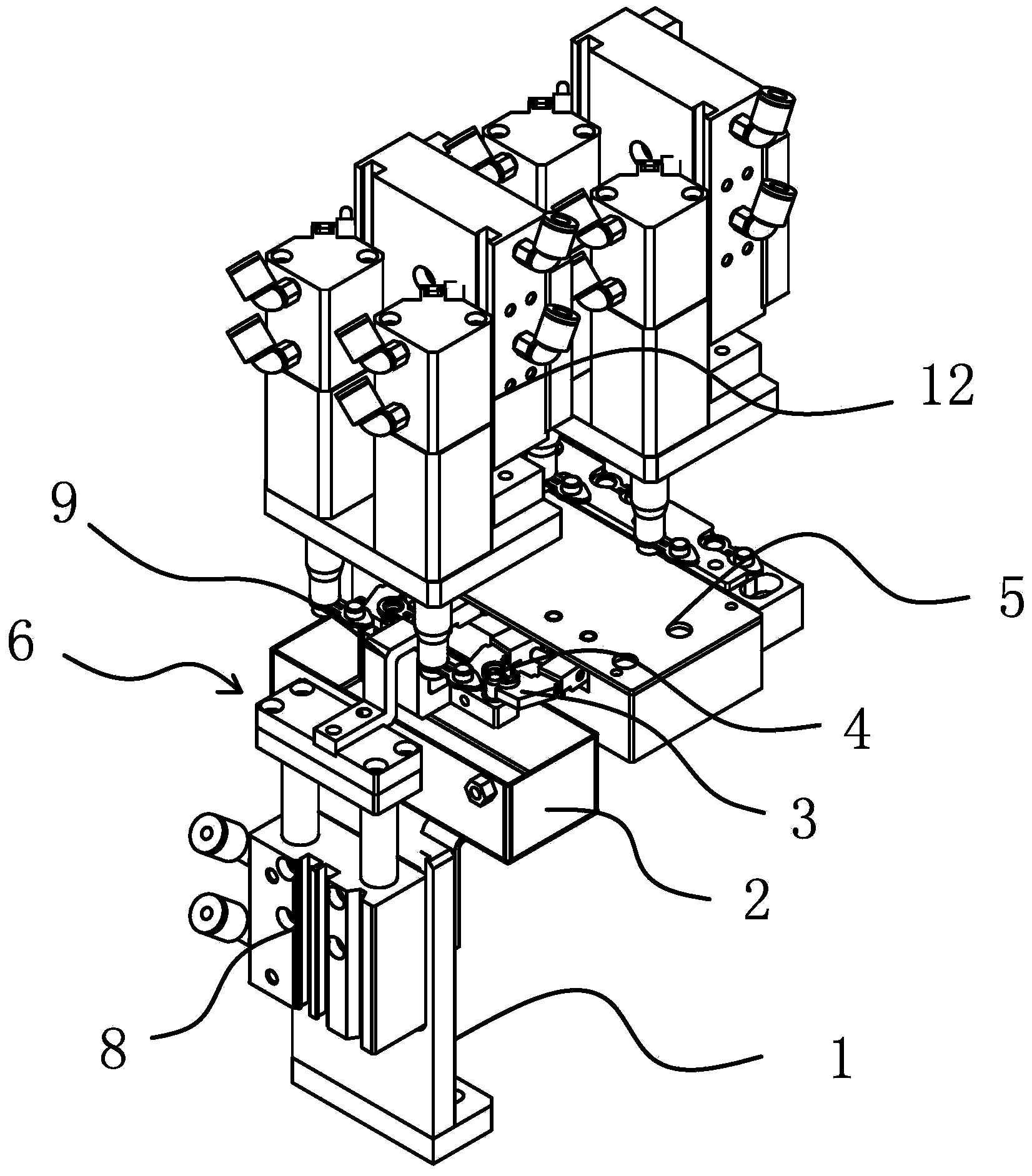

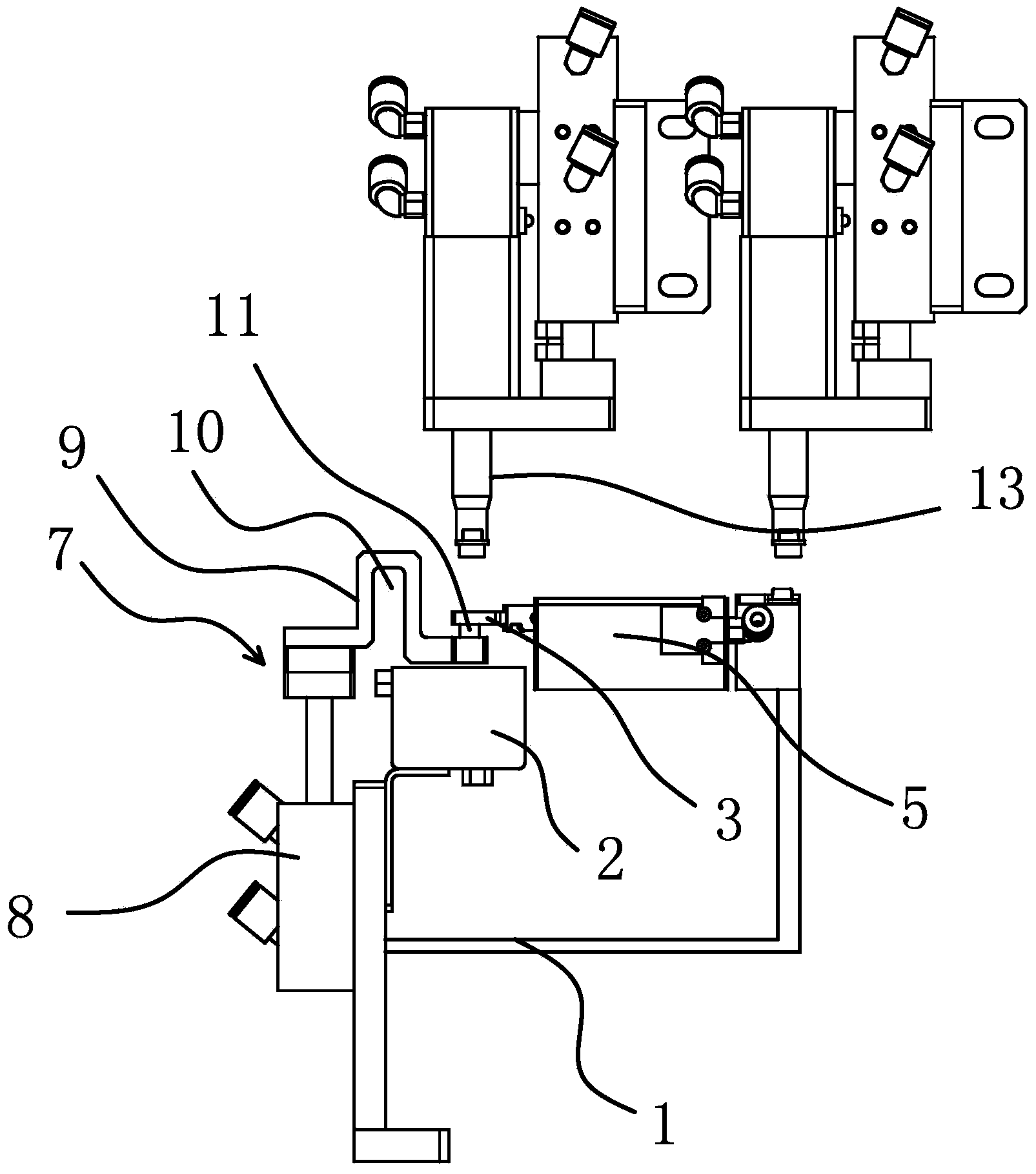

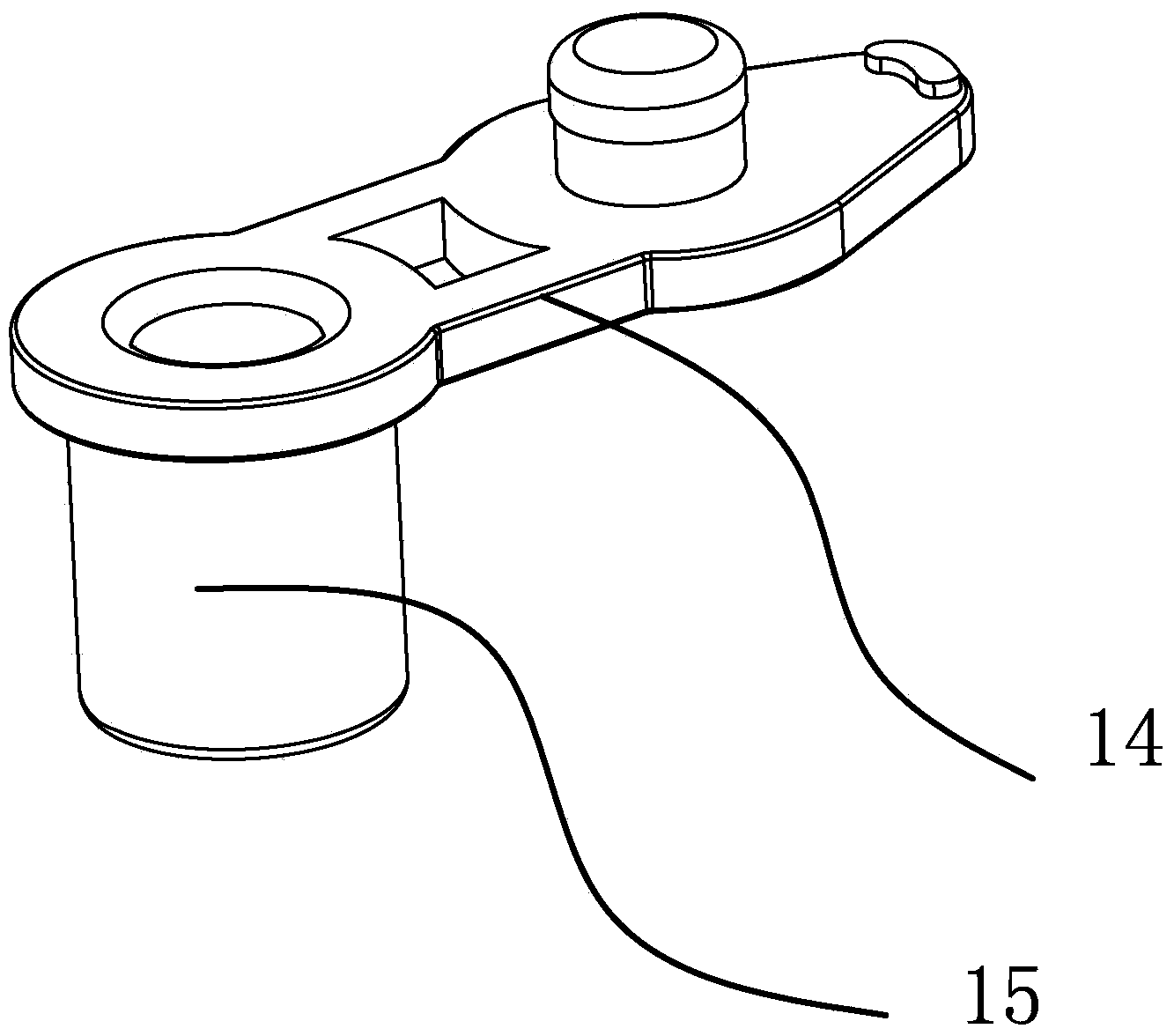

[0032] Such as figure 1 , figure 2 with image 3 Shown, the object of this method is filter cover 14, and filter cover 14 is columnar, and its cylindrical outer surface is glue-coating surface 15, and this glue-coating method comprises the steps:

[0033] a. Feeding: a gluing chuck 3 and a material transfer mechanism 12 are set, and the filter cover 14 is clamped and transferred to the gluing chuck 3 by the material transfer mechanism 12; the material transfer mechanism 12 in step a includes a The material clamp 13, the material removal clamp 13 clamps the outer surface of the filter cover 14 and moves the filter cover 14 to a designated area. The method of clamping the filter cover 14 by the pick-up clip 13 is relatively easy to realize, the structure is simple, and the moving method is easy to design.

[0034]b. Glue dipping: set the glue holding tank 2, put glue in the glue holding tank 2, set a glue dipping mechanism 6, dip the glue in the glue holding tank 2 through t...

Embodiment 2

[0042] Such as Figure 4 As shown, the general content of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, the vertical cylinder 8 is fixed on the top of the mounting plate 9, and the piston rod of the vertical cylinder 8 faces downward and the mounting plate 9 Fixed, the mounting plate 9 is in a "Z" shape, and its advantage is to reduce the bending degree of the mounting plate 9 by changing the position of the vertical cylinder 8.

Embodiment 3

[0044] Such as Figure 5 As shown, the general content of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, the mounting plate 9 is in a “Z” shape, and the length of the mounting plate is changed by the length of the piston rod of the vertical cylinder 8. degree of curvature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com