Abrasive flow wiping fixture for stainless steel pipe

A stainless steel tube and abrasive flow technology, which is applied to abrasives, used abrasive processing devices, manufacturing tools, etc., can solve the problems that stainless steel tubes are prone to deformation and cannot be firmly fixed at the same time, so as to improve the wiping effect and improve wiping efficiency , Insert and fix the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

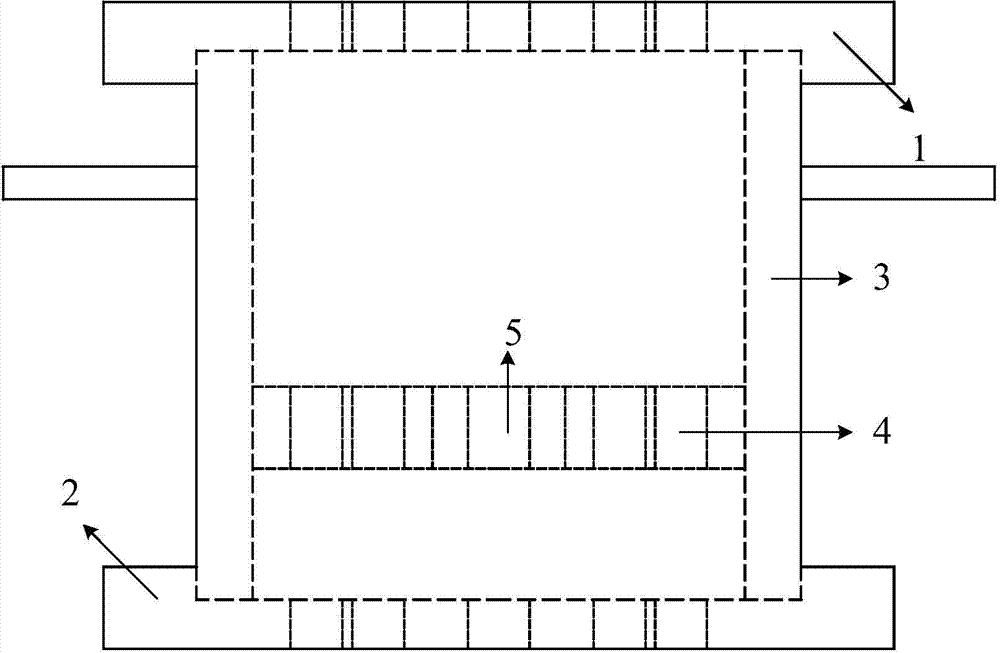

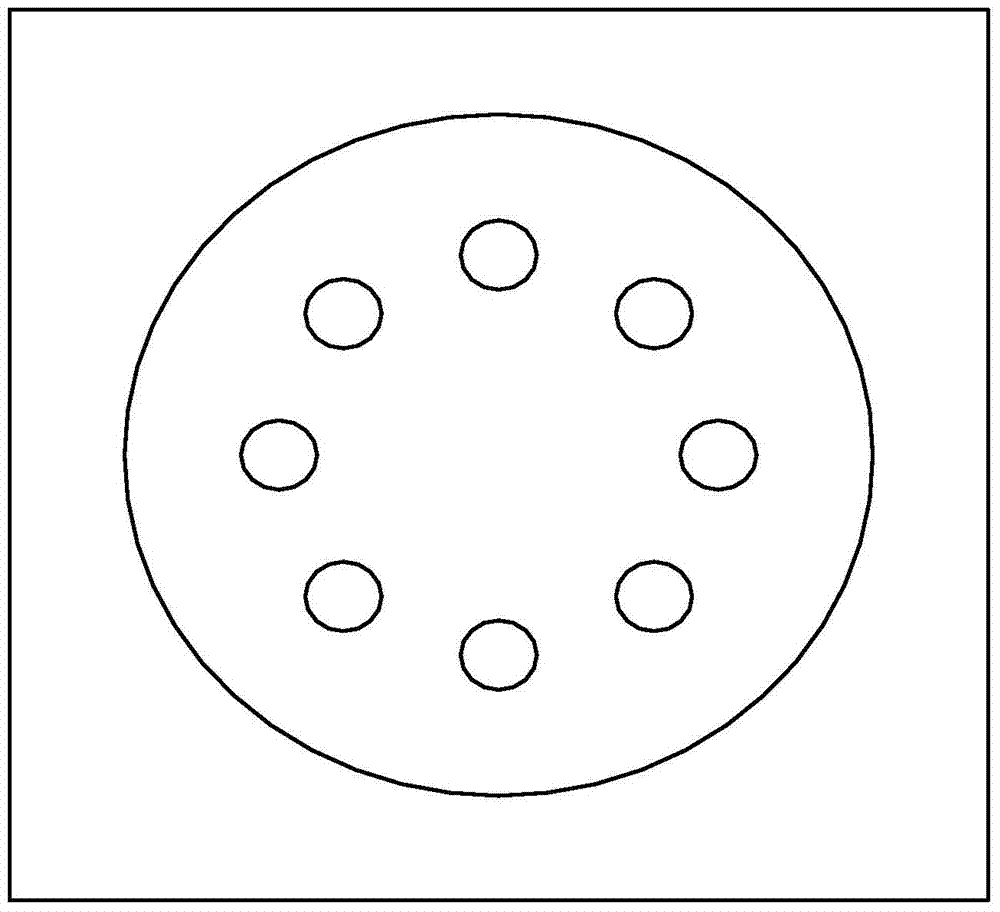

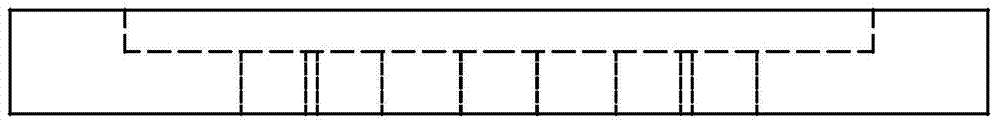

[0030] Such as figure 1 — Image 6 As shown, this embodiment includes an upper retaining guide plate 1, a lower retaining guide plate 2, a bearing sleeve 3 and a limit sleeve 4, the lower surface of the upper retaining guide plate 1 is closely combined with the upper end of the bearing sleeve 3, and the lower retaining guide plate The upper surface of the plate 2 is closely combined with the lower end of the bearing sleeve 3, the limit sleeve 4 is tightly arranged in the load sleeve 3, the limit sleeve 4 is parallel to the upper guide plate 1 and the lower guide plate 2, and the upper guide plate Correspondingly, there are 8 sockets whose diameter is the outer diameter of the stainless steel pipe on the plate 1, the lower retaining guide plate 2 and the limit sleeve 4. On the lower surface of the upper baffle guide plate 1, the center of the upper baffle guide plate 1 is the center of the circle and has a circular concave platform draw-in groove with a diameter of the outer d...

Embodiment 2

[0032] In this embodiment, 16 sockets with a diameter equal to the outer diameter of the stainless steel pipe are correspondingly provided on the upper baffle guide plate 1, the lower baffle guide plate 2 and the limit sleeve 4, and the rest of the structures are the same as in the embodiment 1.

Embodiment 3

[0034] In this embodiment, there are 28 sockets whose diameter is the outer diameter of the stainless steel pipe correspondingly on the upper retaining guide plate 1, the lower retaining guide plate 2 and the limit sleeve 4, and the rest of the structures are the same as in the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com