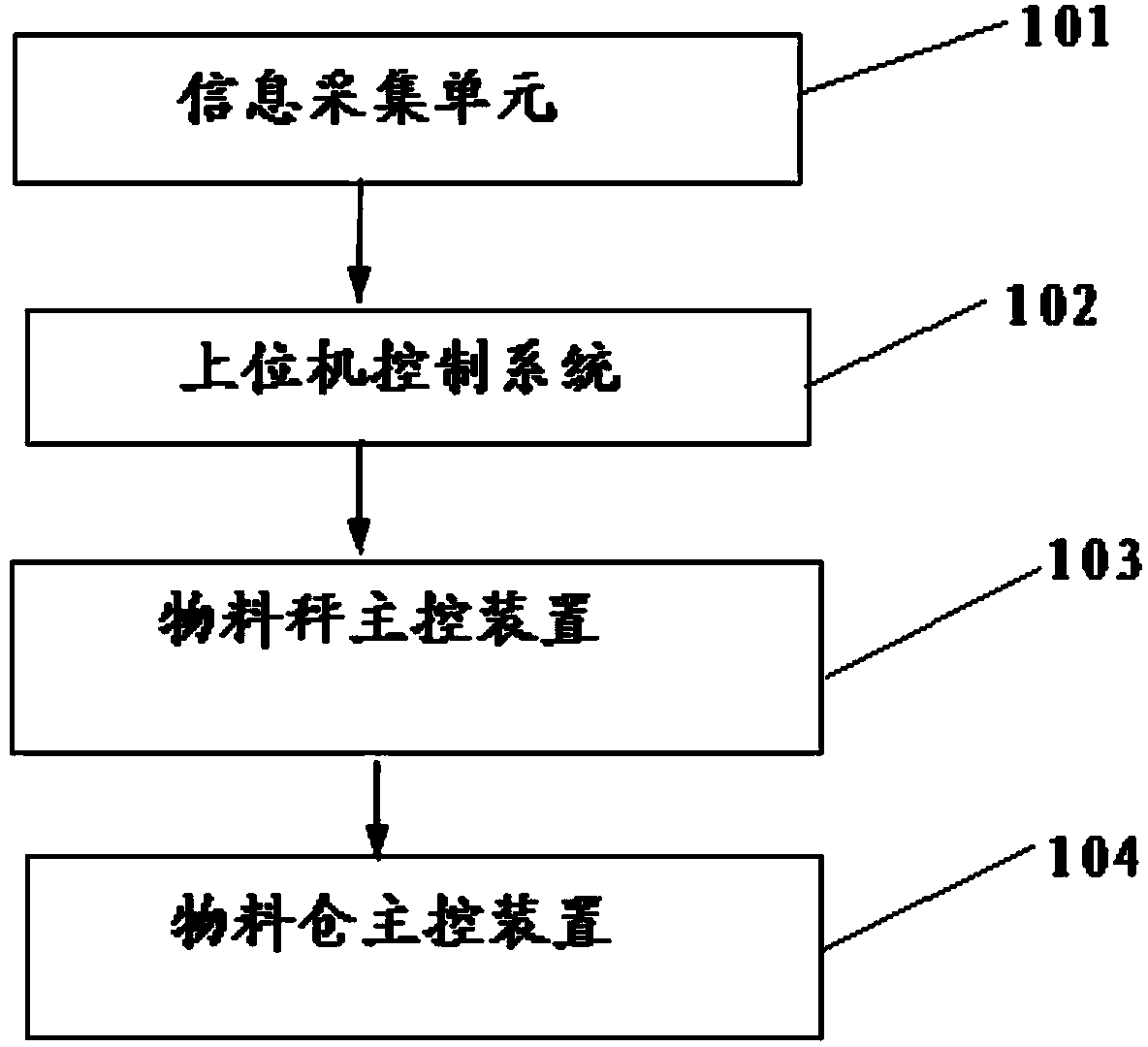

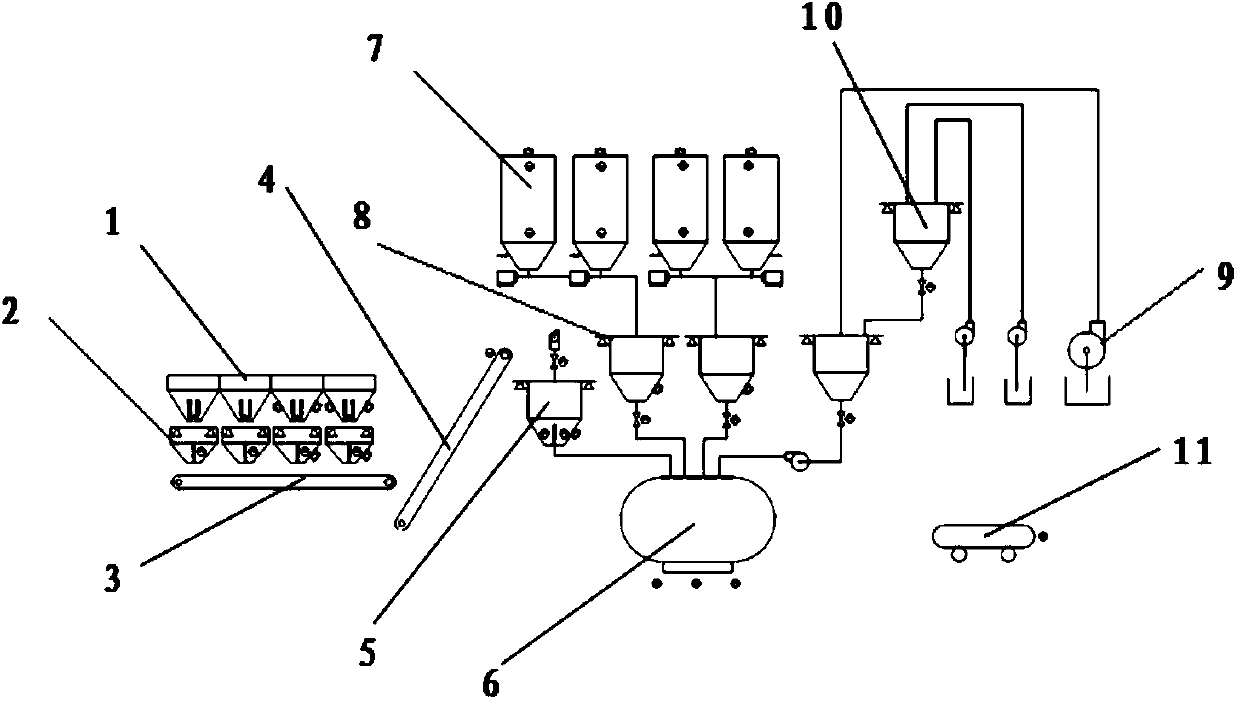

System and method for binding based on concrete production formula and stirring station

A technology for producing formula and concrete, which is applied in mixing plants, chemical instruments and methods, and clay preparation devices, etc. It can solve the problem that material scales cannot be replaced, material bins cannot be replaced with each other, and the corresponding relationship between material scales and material bins and the corresponding quantity cannot be changed. and other issues to achieve the effect of satisfying production materials and increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The technical solutions of the present invention will be further described in detail below through the accompanying drawings and embodiments.

[0044] It should be noted that any technical feature and any technical solution in this embodiment are one or more of a variety of optional technical features or optional technical solutions. For the sake of brevity of description, this document cannot be exhausted. Taking all the alternative technical features and alternative technical solutions of the present invention, it is not convenient for the implementation of each technical feature to emphasize that it is one of the multiple alternative implementations, so those skilled in the art should know: Any technical features and any technical solutions in the embodiments do not limit the protection scope of the present invention, and the protection scope of the present invention should include any alternative technical solutions that those skilled in the art can think of without cre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com