Hard water-resisting high-performance cold rolling emulsion and preparation method thereof

An emulsion, high-performance technology used in the field of lubrication to solve problems such as increasing the probability of failure and increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] 1. 1. Extreme pressure type

[0008] Example 1 formula is as follows:

[0009] serial number

component name

Mass percentage%

1

N32

22.5

2

coconut oil

36.0

3

lard

13.5

4

Pentaerythyl Oleate

10.0

5

Modified Phosphate

2.8

6

sulfurized fatty acid ester

4.2

7

vulcanized lard

4.0

8

T702

3.0

9

TX series emulsifier

2.0

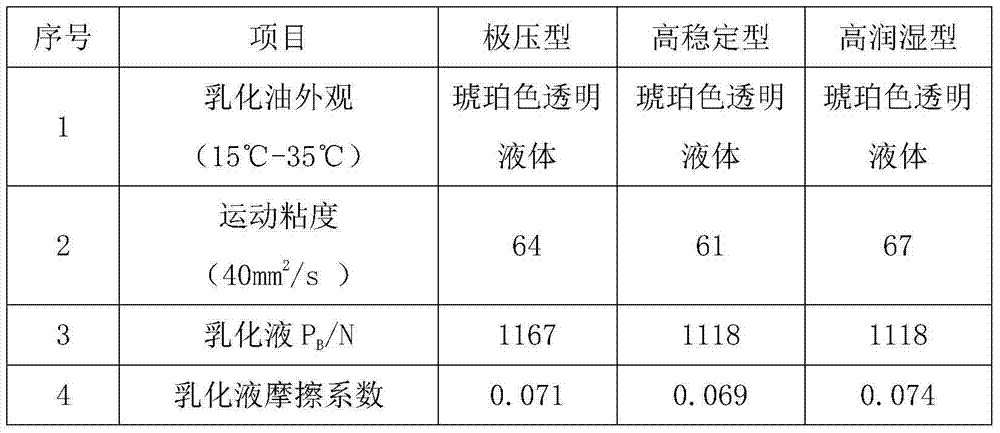

[0010] After adding other components in the beaker except emulsifier according to the ratio in the above table, put it into a magnetic stirrer, stir at 75°C at a speed of 3000-4000rpm for 20 minutes, then cool to below 60°C, add emulsifier to Stir at the same speed for 30 minutes to obtain a stable amber transparent oil, which is the prepared emulsified oil. When in use, add tap water to dilute to 3%-5% as needed, fully stir and oscillate evenly to form the desired emulsion. The emulsion prepared by th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com