Method for ultrasonic removal of carbon deposition

An ultrasonic and carbon deposition technology, applied in the field of carbon deposition, can solve the problems of scrapped parts and easily damaged substrates, and achieve the effects of preventing excessive corrosion, increasing stirring effect, and achieving obvious effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

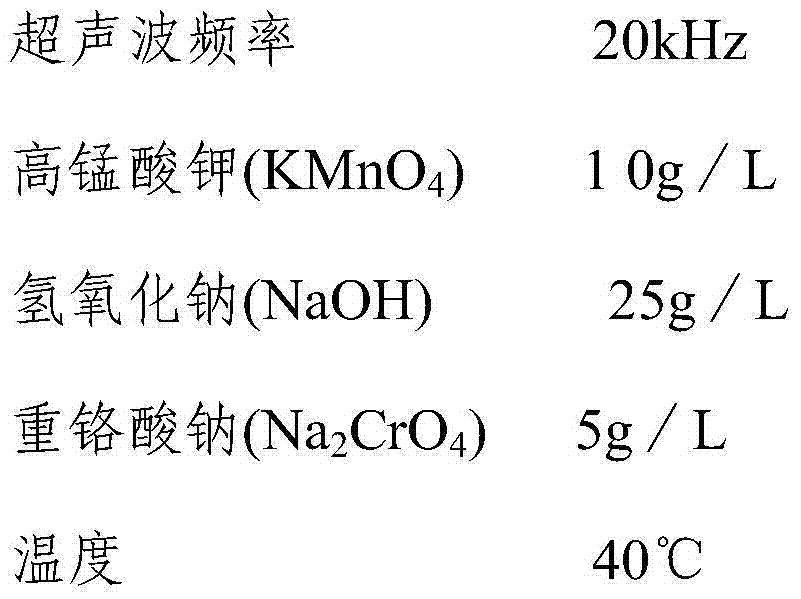

Embodiment 1

[0017]

[0018] Using the above process formula, remove carbon deposits according to the process of removing carbon deposits on fuel nozzles. The carbon deposits on the surface of fuel nozzles are removed cleanly, showing a metallic luster matrix. The carbon deposit removal time is about 3 hours.

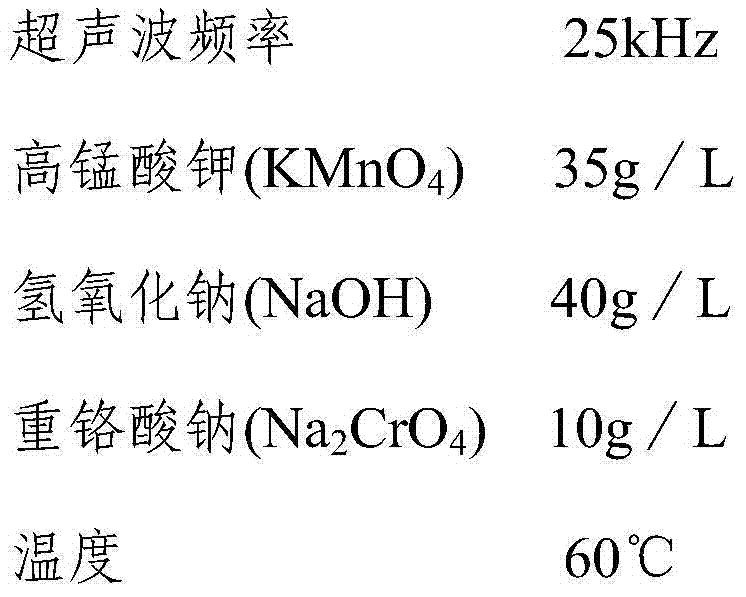

Embodiment 2

[0020]

[0021] Using the above process formula, remove carbon deposits according to the process of removing carbon deposits on fuel nozzles. The carbon deposits on the surface of fuel nozzles are removed cleanly, showing a metallic luster matrix. The carbon deposit removal time is about 1 hour.

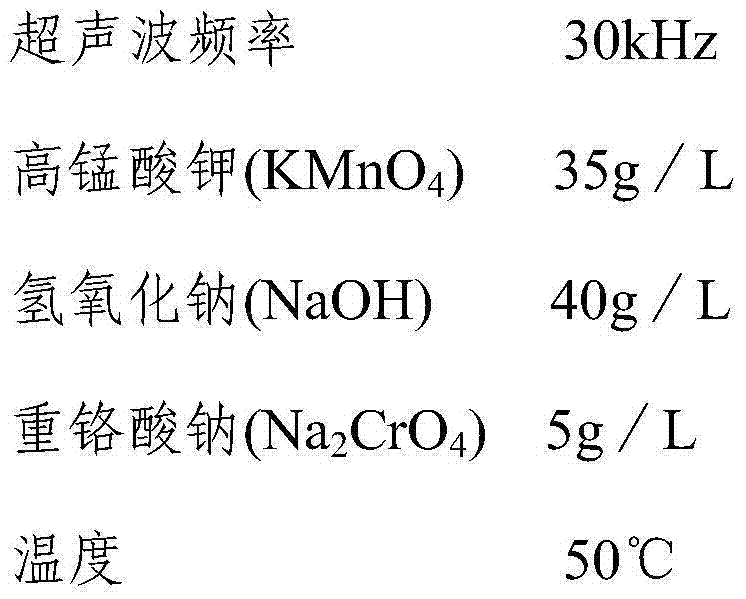

Embodiment 3

[0023]

[0024] Using the above process formula, remove carbon deposits according to the process of removing carbon deposits on fuel nozzles. The carbon deposits on the surface of fuel nozzles are removed cleanly, showing a metallic luster matrix. The carbon deposit removal time is about 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com