Static seal structure of dish-shaped ring

A static sealing and disc-shaped technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of poor operability and high cost, and achieve the effects of easy compression deformation, improved sealing performance, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

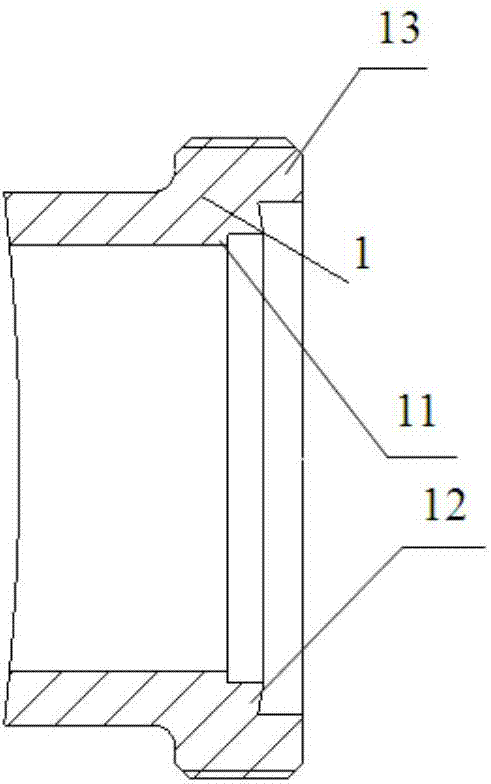

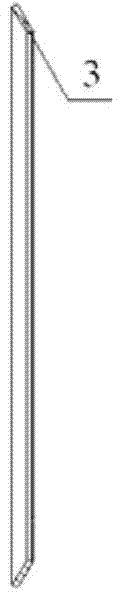

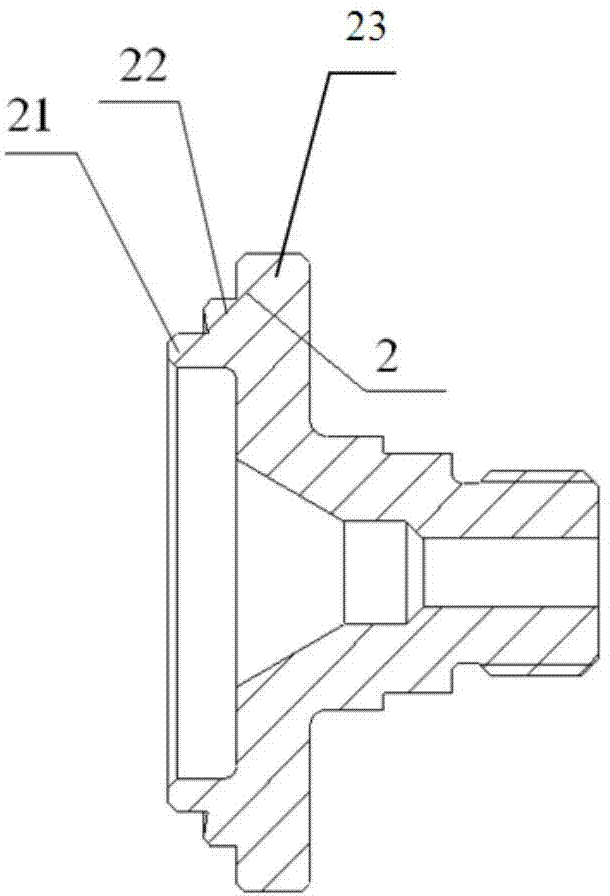

[0025] Such as Figure 5 As shown, the disc ring static sealing structure is composed of two first metal parts 1, second metal parts 2, disc rings and threaded connectors that need to be sealed. figure 1 As shown, the first metal part is provided with an inner step 11, a convex sealing step 12 and a convex limiting step 13 in sequence along the center to the periphery; image 3 As shown, the second metal part is provided with an outer step 21, a concave sealing step 22 and a concave limit step 23 in sequence along the center to the periphery, the inner step is compatible with the outer step, and the convex sealing step is compatible with the concave sealing step. The convex limit step is compatible with the concave limit step, and the disc ring is located between the convex sealing step and the concave sealing step. The fastener exerts an axial force through the thread of the convex limit step, so that the convex sealing step is matched with the concave sealing step through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com