Optical film locating device

一种光学膜片、定位装置的技术,应用在光学、照明装置、光源固定等方向,能够解决暗影、光学膜片变形弯曲、影响背光模组成像品质等问题,达到提高品质、保证平整度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

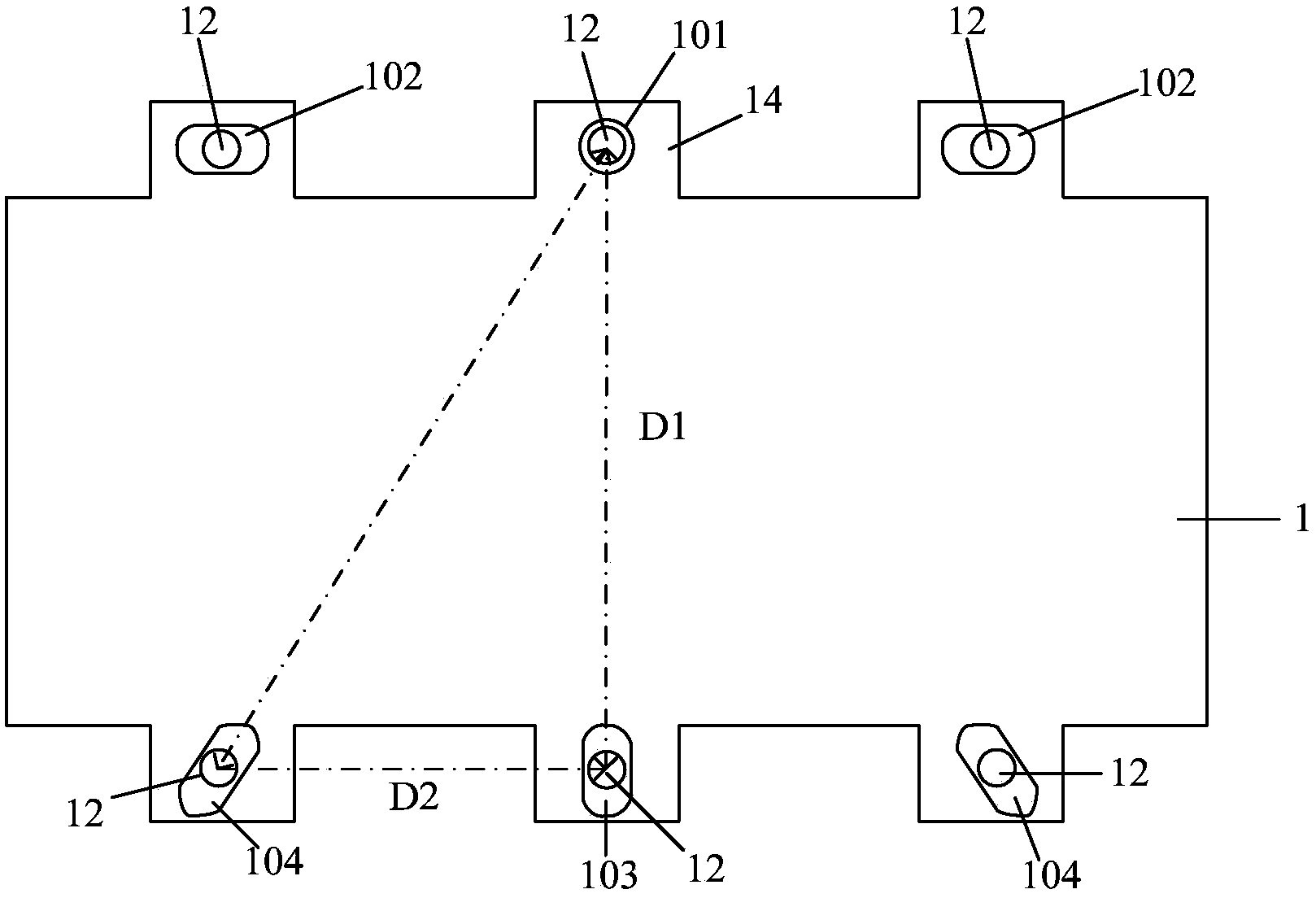

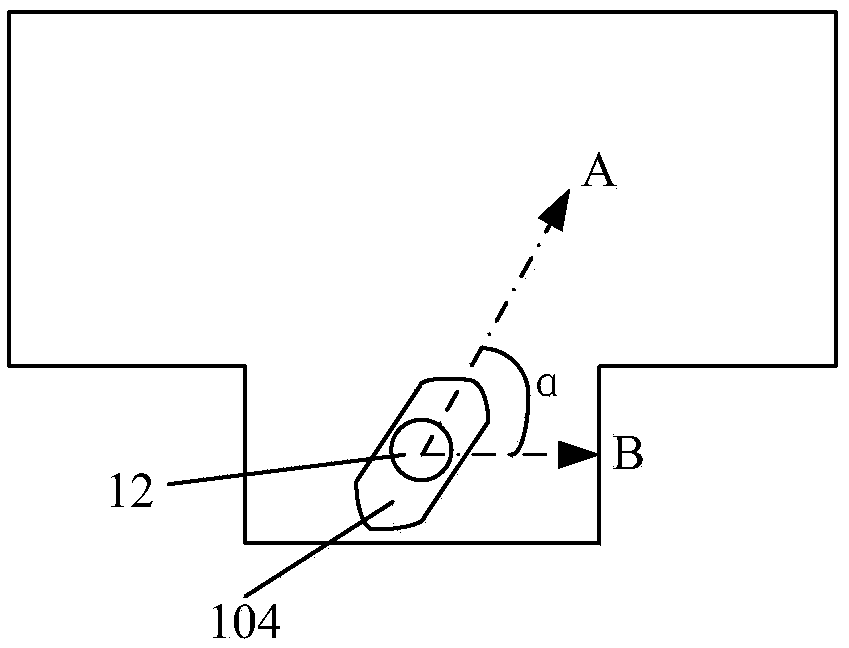

[0012] In order to strengthen the positioning of the optical diaphragm, and to avoid the interference of the positioning column with the positioning hole when the optical diaphragm expands with heat and contracts with cold, to ensure the smoothness of the optical diaphragm, refer to figure 1 As shown, the present invention provides a positioning device for an optical film, comprising a positioning hole 10 provided on the optical film 1 and a positioning post 12 inserted into the positioning hole 10, through which the positioning post 12 passes through the positioning hole 10, and the The optical film 1 is fixed on the carrier substrate, and the shapes of the positioning holes 10 respectively extend in the contraction and expansion directions of the corresponding positions of the optical film 1 .

[0013] The optical film 1 is suitable for a backlight module, such as a diffusion sheet, a prism sheet, an enhancement film, etc., to improve the brightness and taste of the backlight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com