Method for measuring three-dimensional roughness of rock mass structural surface based on triangle area ratio method

A technology of structural surface and area ratio, applied in measurement devices, instruments, optical devices, etc., can solve the problems that cannot be applied in engineering, the results vary greatly, and there are few research theories.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

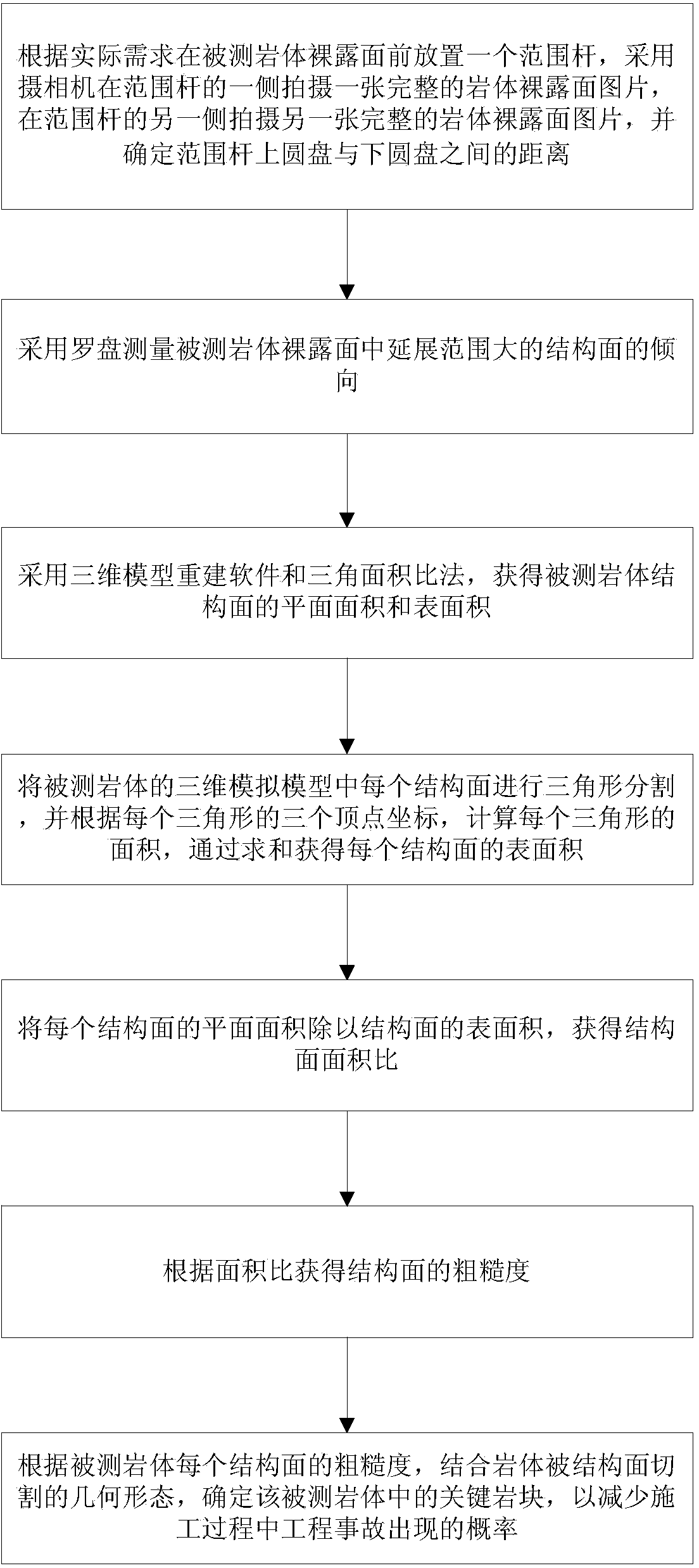

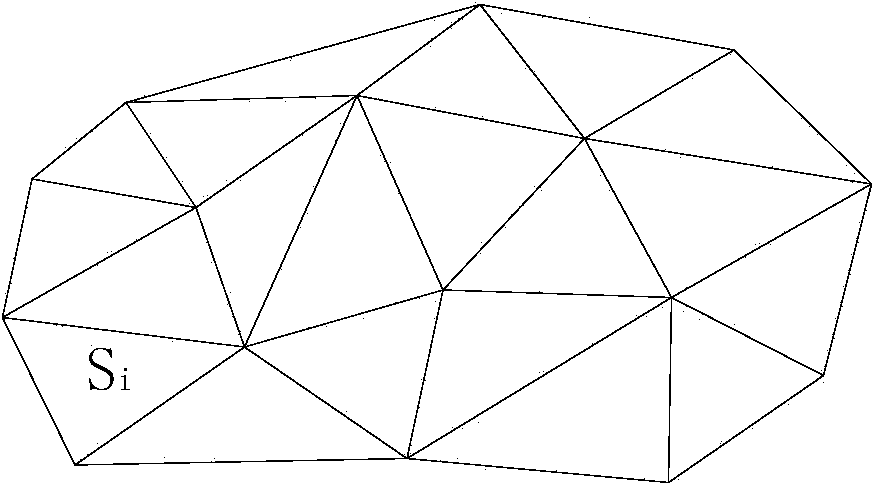

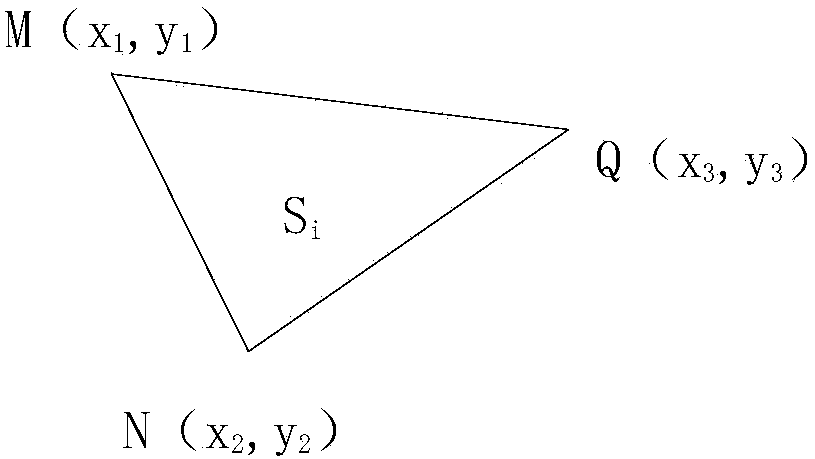

[0053] A method for measuring the three-dimensional roughness of rock mass discontinuities based on the triangular area ratio method, the flow chart of the method is as follows figure 1 shown, including the following steps:

[0054] Step 1. Place a range rod in front of the exposed rock mass according to actual needs, use a camera to take a complete picture of the exposed rock mass on one side of the range rod, and take another complete picture on the other side of the range rod. The picture of the exposed surface of the rock mass, and determine the distance between the upper disc and the lower disc of the range rod;

[0055] In the embodiment of the present invention, the range bar is an accessory product of the ShapeMetrix3D three-dimensional model reconstruction software system, a supporting device produced by the same manufacturer, and is an existin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com