Weight swing prevention gap clamping mechanism for small-torque standard device

A standard device and clamping mechanism technology, applied in the direction of measuring devices, force/torque/power measuring instrument calibration/testing, instruments, etc., can solve problems such as weight and weight frame swing, and achieve automatic clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the drawings and embodiments:

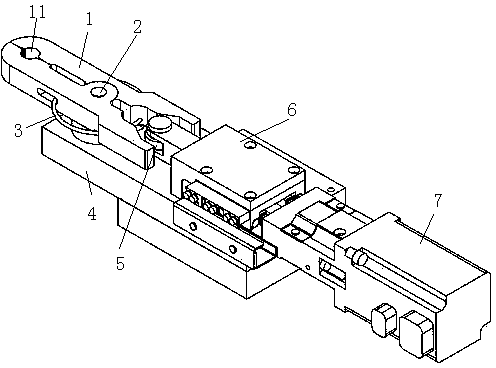

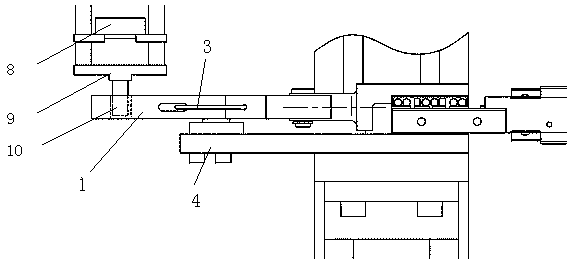

[0014] Such as figure 1 As shown, a weight anti-swing gap clamping mechanism for a small torque standard device mainly includes: clamping pliers 1, pin 2, spring 3, base 4, bearing 5, bearing frame 6 and linear motion drive mechanism 7 .

[0015] The clamping forceps 1 is divided into left and right lobes, the two lobes have the same structure and are placed symmetrically. There is a connecting through hole in the middle to allow the pin 2 to pass through. The pin 2 is fixedly connected with the bottom base 4. At the same time, the pin 2 is used as a fulcrum, and the two parts of the clamping pliers 1 can rotate around the pin. An arc-shaped spring 3 passes through the middle part of the clamp 1. The spring 3 gives an inward pressing force to the tail of the clamping pliers, so that the front end of the clamping pliers 1 is in an open state when it is not a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com