Method for determining quantity of fed specimens in breathable cylinder of brinell breathable specific surface area instrument

A technology of specific surface area and cylinder, which is applied in the field of determination of the amount of test material contained, can solve problems such as pollution, and achieve the effect of avoiding serious pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

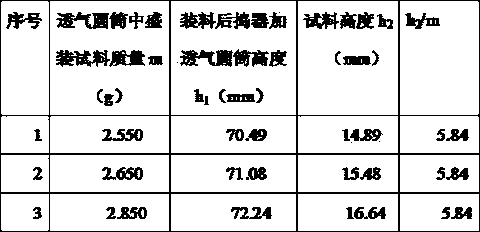

Embodiment 1

[0028] A method for determining the amount of sample loaded in the venting cylinder of a Blaine air-permeable specific surface area meter, the specific steps of which are as follows:

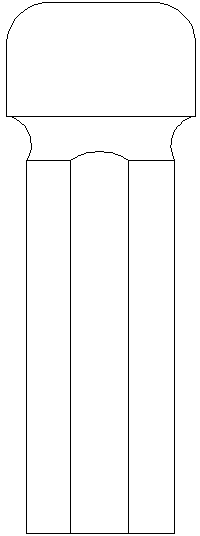

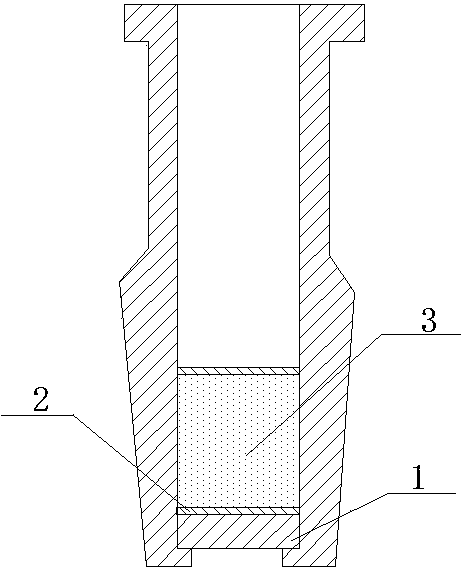

[0029] Step 1. Measure the relevant parameters of the venting cylinder and the tamper of the Blaine air permeable specific surface area meter: measure the distance a from the lower edge of the perforated plate of the perforated cylinder to the lower edge of the perforated cylinder, the thickness b of the perforated plate 1, and the thickness c of the two filter papers , the height of the tamper f, the height g of the tamper plus the air-permeable cylinder when the support ring of the tamper tightly contacts the top edge of the cylinder when no material is loaded; Edge distance a=4.10 mm; perforated plate 1 thickness b=1.00 mm; two filter paper 2 thickness c=0.30 mm; tamper height f=50.20 mm; the support ring of the tamper tightly contacts the top edge of the cylinder when no material is loaded T...

Embodiment 2

[0036] A method for determining the amount of sample in a ventilating cylinder of a Blaine air-permeable specific surface area meter, the specific operating steps of which are: a method for determining the amount of sample in the air-permeable cylinder of a Blaine air-permeable specific surface area meter, the specific operating steps of which are as follows:

[0037] Step 1. Measure the relevant parameters of the venting cylinder and the tamper of the Blaine air permeable specific surface area meter: measure the distance a from the lower edge of the perforated plate 1 of the perforated cylinder to the lower edge of the perforated cylinder a, the thickness b of the perforated plate 1, and the thickness of the two filter papers 2 c. The height of the tamper f, the height g of the tamper plus the air-permeable cylinder when the support ring of the tamper tightly contacts the top edge of the cylinder when no material is loaded; The distance from the lower edge a=4.10 mm; the thick...

Embodiment 3

[0044] A method for determining the amount of sample in a ventilating cylinder of a Blaine air-permeable specific surface area meter, the specific operating steps of which are: a method for determining the amount of sample in the air-permeable cylinder of a Blaine air-permeable specific surface area meter, the specific operating steps of which are as follows:

[0045] Step 1. Measure the relevant parameters of the venting cylinder and the tamper of the Blaine air permeable specific surface area meter: measure the distance a from the lower edge of the perforated plate 1 of the perforated cylinder to the lower edge of the perforated cylinder a, the thickness b of the perforated plate 1, and the thickness c of the two filter papers , the height of the tamper f, the height g of the tamper plus the air-permeable cylinder when the support ring of the tamper tightly contacts the top edge of the cylinder when no material is loaded; Edge distance a=4.10 mm; perforated plate 1 thickness ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap