An Automatic Control Method Based on Taping Parameters

A parameter and tape technology, applied in the field of automatic control based on tape parameters, can solve problems such as low work efficiency, production errors, wrong parameters, etc., and achieve the effect of saving labor costs, high automation, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

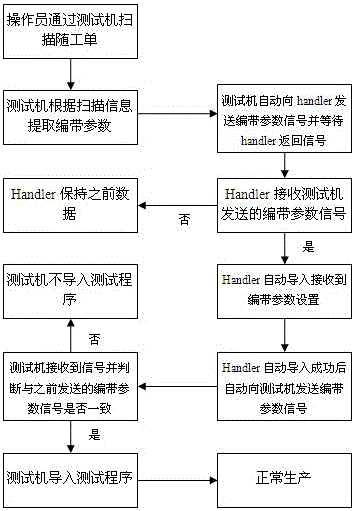

[0024] like figure 1 As shown, an automatic control method based on taping parameters, it includes the following steps:

[0025] S1: The operator scans the peripheral device information through the testing machine;

[0026] S2: The testing machine extracts the taping parameters according to the scanning information;

[0027] S3: The testing machine automatically sends the taping parameter signal to the processor, and waits for the microprocessor to return the signal;

[0028] S4: The microprocessor receives the taping parameter signal sent by the testing machine, and automatically imports the received taping parameter setting;

[0029] S5: After the automatic import of the microprocessor is successful, it will automatically send the tapi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com