Oil/fat composition

An oil composition and oil phase technology, which is applied in the production/processing of edible oil/fat, edible oil/fat phase, edible oil/fat, etc., can solve the problems of reduced appearance, storage stability, poor mouth solubility, etc. Good emulsification stability, excellent sugar absorption, and excellent mouth melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

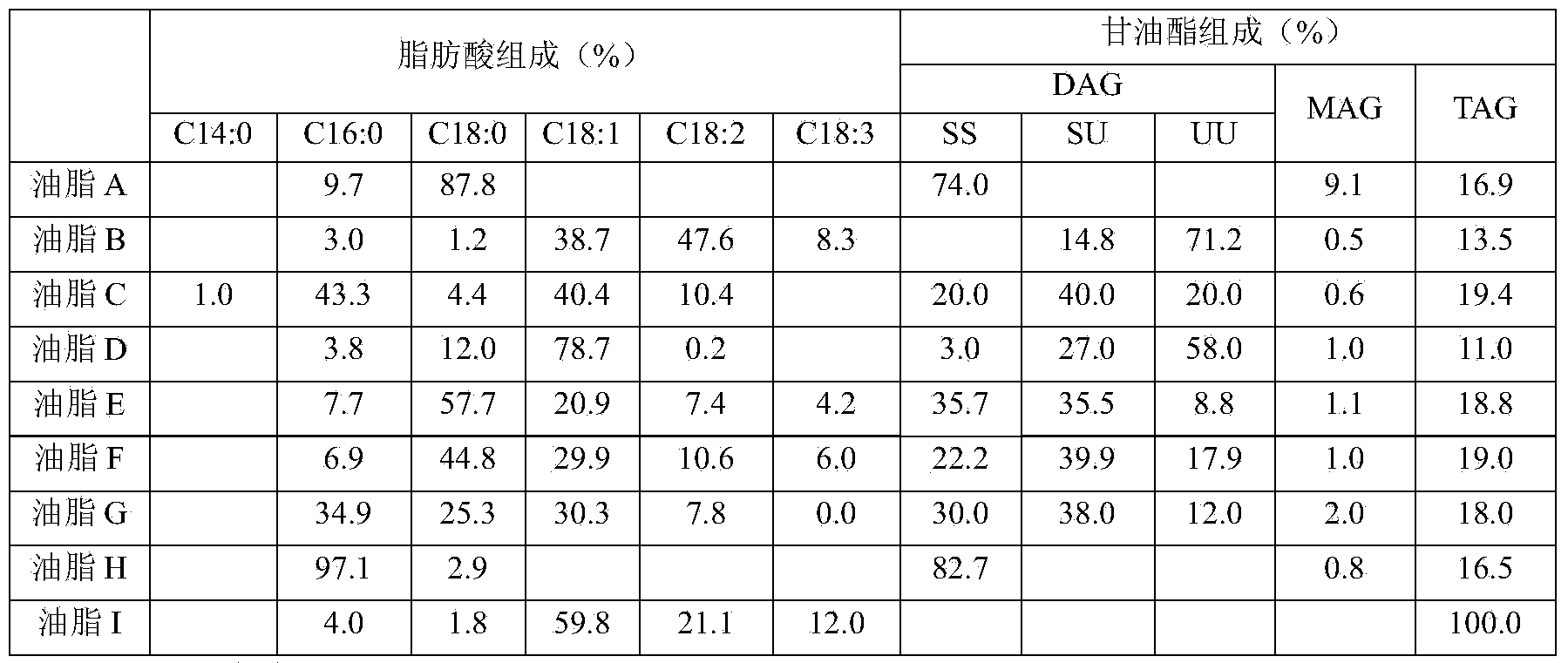

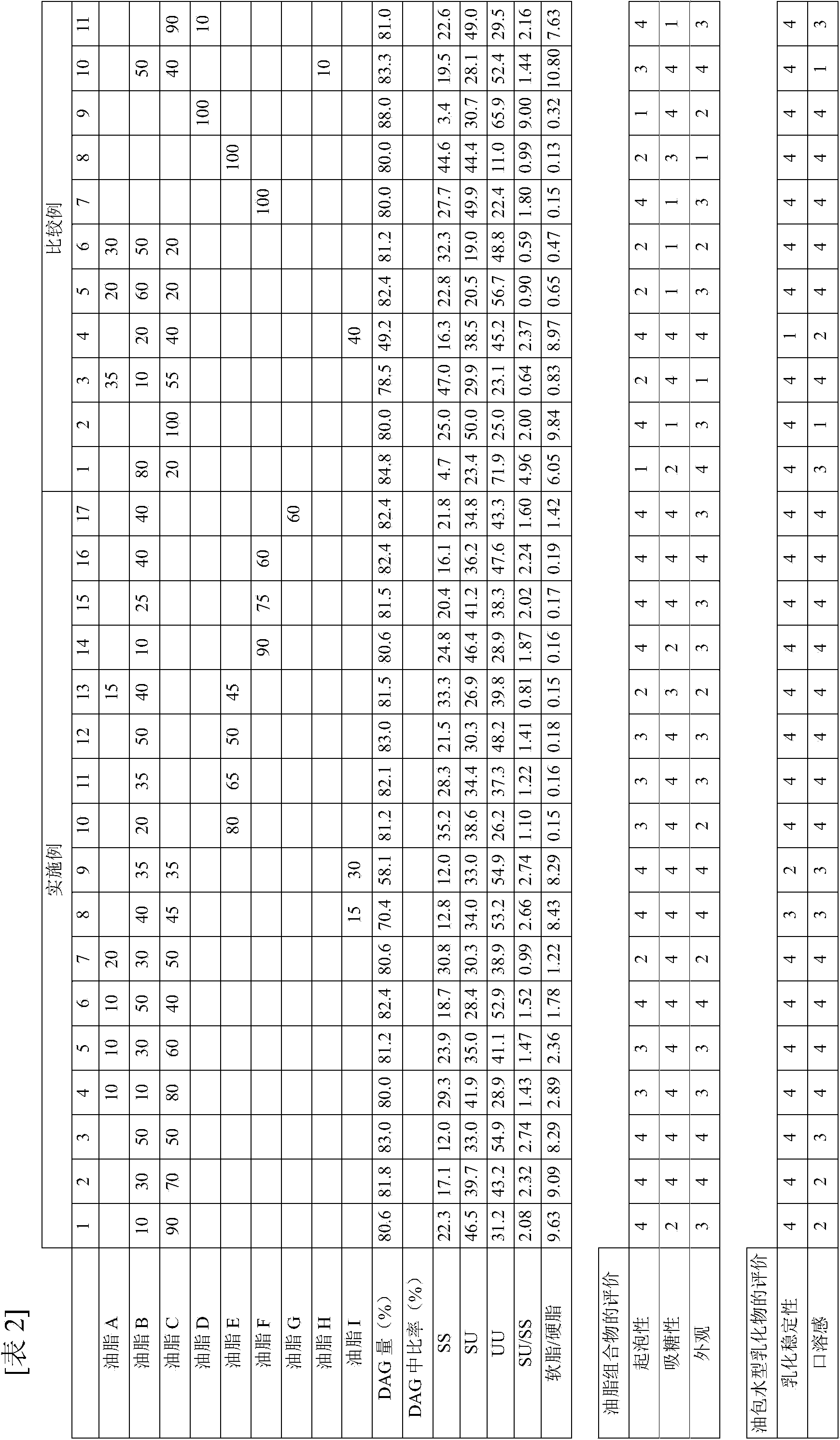

Embodiment 1~17 and comparative example 1~11

[0103] (1) Preparation of oil composition

[0104] Greases A to I were mixed according to the ratio shown in Table 2, and melted at 80° C. to form a homogeneous mixture. The mixture was cooled to 25° C. while kneading using a cooler (emulsification kneader, Tama Seiki Kogyo Co., Ltd.), to obtain an oil and fat composition. The obtained oil and fat composition was stored at 5° C. for 1 day, and then stored at 20° C. for 1 day, and then stored in a refrigerator (5° C.) to obtain a fat and oil sample. Evaluate the appearance, foaming and sugar absorption of oil and fat samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com