Drive unit for at least one traction device

A technology for driving units and traction devices, which is applied to devices used in theaters, circuses, etc., clockwork mechanisms, entertainment, etc., to achieve the effects of low driving noise and small axial length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

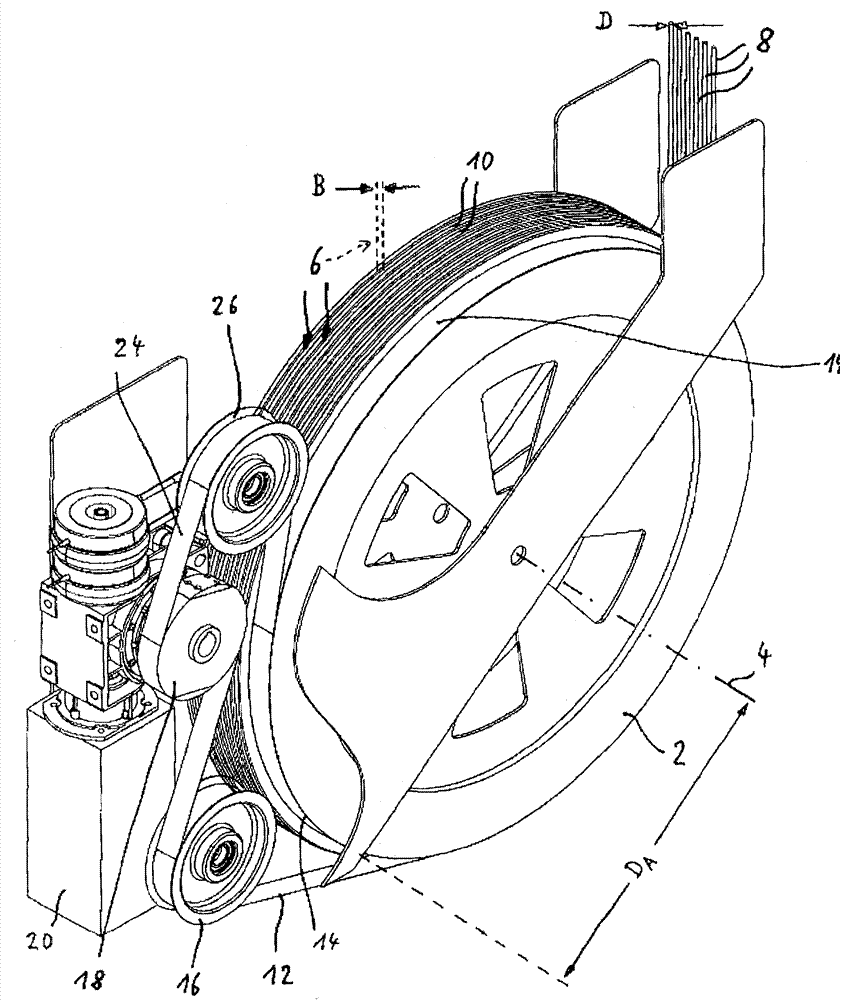

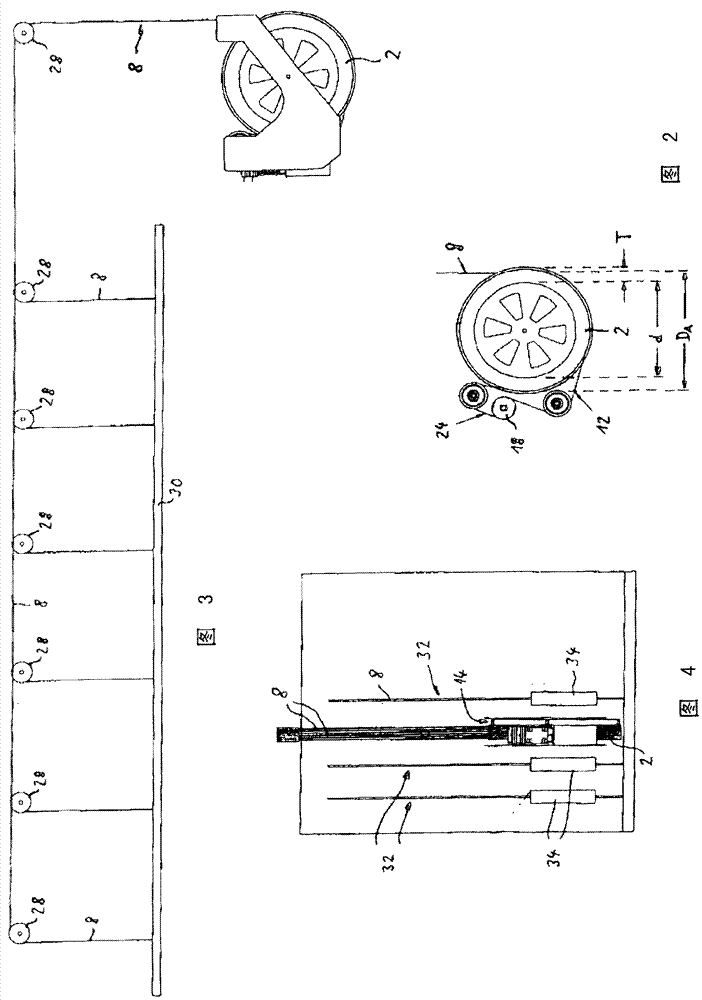

[0020] figure 1 A perspective view of a complete drive unit for a scenery lifter in a stage machine is shown with a winding drum 2 driven rotatably about an axis of rotation 4 . The winding drum 2 has six winding areas 6 arranged next to each other for individual pulling means (in this embodiment, pulling ropes 8 ), which are configured in the form of receiving spaces with a base diameter d, which are groove-shaped or shaped like a cylindrical ring and extend radially to the axis of rotation 4 and are in each case separated from each other by a narrow partition 10 arranged between them. The clear width B of each take-up area 6 corresponds to the diameter D of the traction rope (or the width of the traction belt) received therein or slightly larger, so that the traction means involved can be wound up to the coil-up area without difficulty 6 in. For this purpose, the end of each pulling means 8 on the side of the winding drum is fixed to said winding drum 2 at the base of its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com