Imaging element module and method for manufacturing same

A technology of an imaging element and a manufacturing method, which is applied in the directions of electrical components, assembling printed circuits with electrical components, and image communication, etc., can solve the problems of contamination of the light-receiving surface, difficulty in storage, and no consideration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

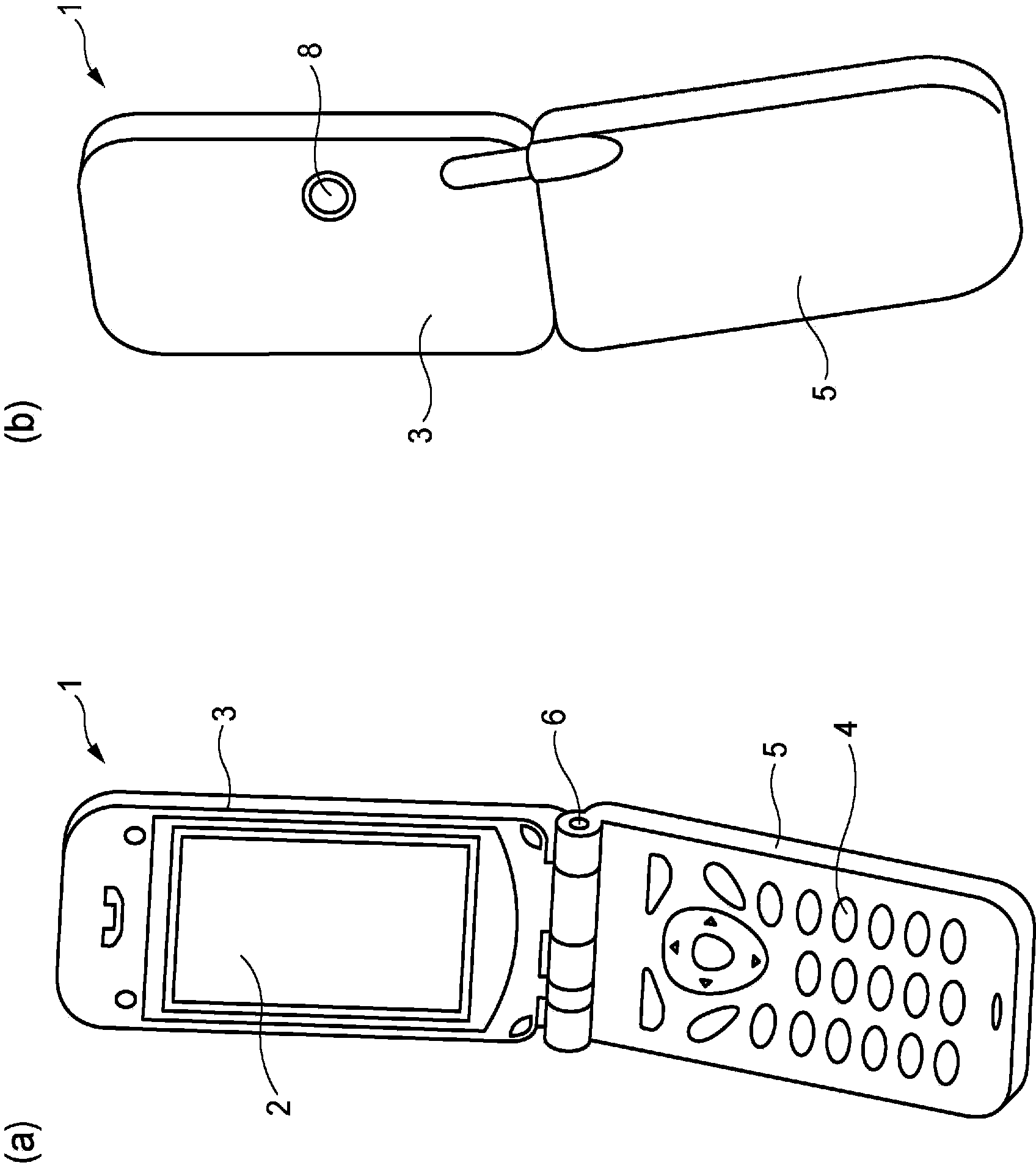

[0025] figure 1 (a) and (b) are external views of a foldable mobile phone, which is an example of a small electronic device equipped with an imaging device module according to an embodiment of the present invention. In this foldable mobile phone 1 , an upper housing 3 on which a liquid crystal display unit 2 is mounted and a lower housing 5 on which keys 4 and the like are mounted are foldably connected by a hinge portion 6 .

[0026] The liquid crystal display unit 2 of the upper housing 3 is constituted by a large display device covering most of the front side of the upper housing 3 , and a camera (imaging element) module is also incorporated in the upper housing 3 . figure 1 (b) shows the back side of the mobile phone 1 , and the photographing lens 8 of the camera is exposed from the opening on the back side of the upper housing 3 . That is, since the camera m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com