A water-cooled molding tool for a vehicle cushion pad

A technology for cushioning pads and vehicles, which is applied in the field of fixtures, can solve the problems of affecting production efficiency, high production time requirements, and long time, so as to prevent the shrinkage of the inner cavity or the shrinkage and change of the distance between the metal protrusions, shorten the production cycle, and improve the production efficiency. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

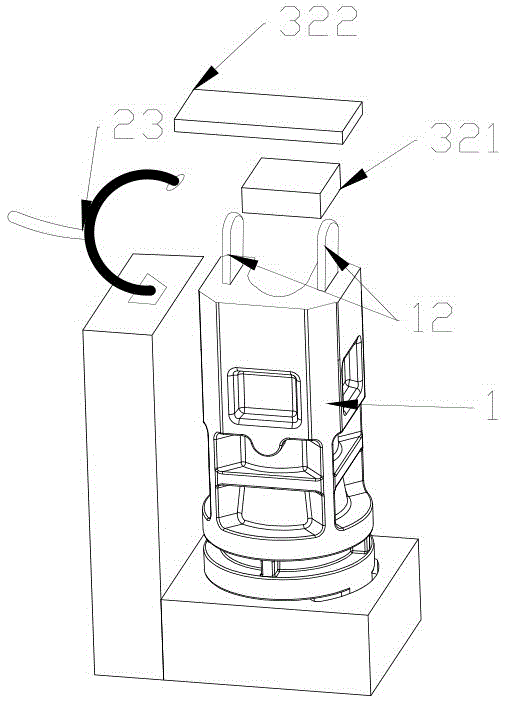

[0014] Embodiment one, such as image 3 As shown, the positioning block 321 is a rectangular block whose width matches the specification spacing of the two metal protruding feet 12, and the positioning block 321 is embedded between the two metal protruding feet 12 to avoid the shrinkage of the two metal protruding feet during the cooling process. The distance between the protruding feet changes; the pressure equalizing plate 322 is covered on the top 1 of the vehicle cushion next to the metal protruding feet 12 , and the locking lever 23 is crimped on the pressure equalizing plate 322 . During specific implementation, put the injection-molded uncooled vehicle cushion into the water-cooled shaping tool, place the open inner cavity of the vehicle cushion in a matching manner with the punch, and then insert the positioning block between the two metal protruding feet, and then Set the pressure equalizing plate cover on the top of the vehicle cushion, lock the lever to press and fi...

Embodiment 2

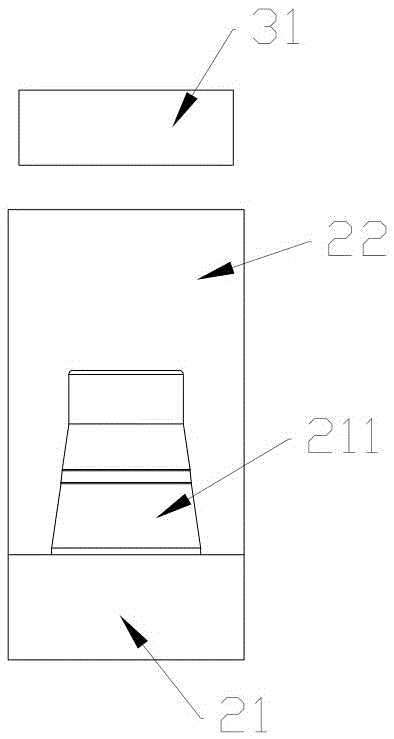

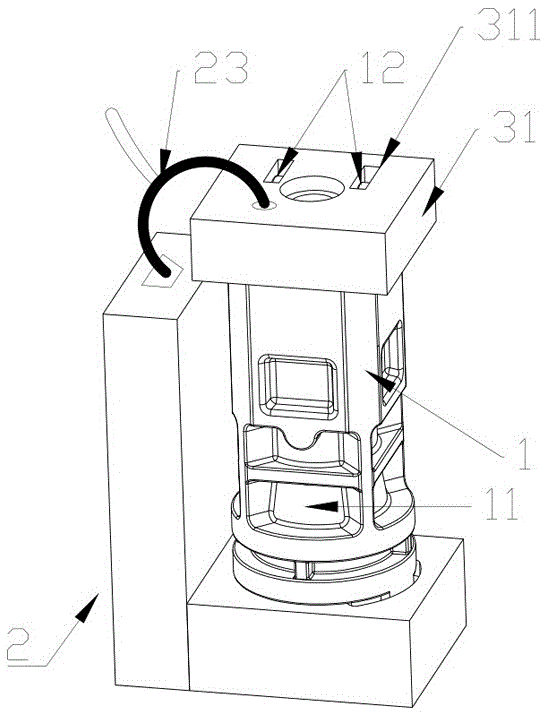

[0015] Embodiment two, such as figure 1 and 2 As shown, the positioning block 321 and the pressure equalizing plate 322 are integrally formed and have two pressing blocks 31 with slots 311. The spacing between the slots 311 matches the spacing between the two metal protruding feet 12; the pressing block 31 is sleeved on the metal protruding pins The foot 12, and the locking lever 23 is crimped on the pressing block 31. During specific implementation, put the injection-molded uncooled vehicle cushion into the water-cooled shaping tool, match the open inner cavity of the vehicle cushion with the punch, and then place the briquetting block on the top of the vehicle cushion. The protruding feet are connected to the grooves of the press block, and the press block is against the top of the vehicle cushion, and the locking lever presses and fixes the press block, and finally the water-cooled shaping tool loaded with the vehicle cushion is placed in the water tank to cool After the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com