Water pump shell shaping device and operation method thereof

A pump casing and water pump technology, applied in the field of pump casing shaping, can solve problems such as product damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

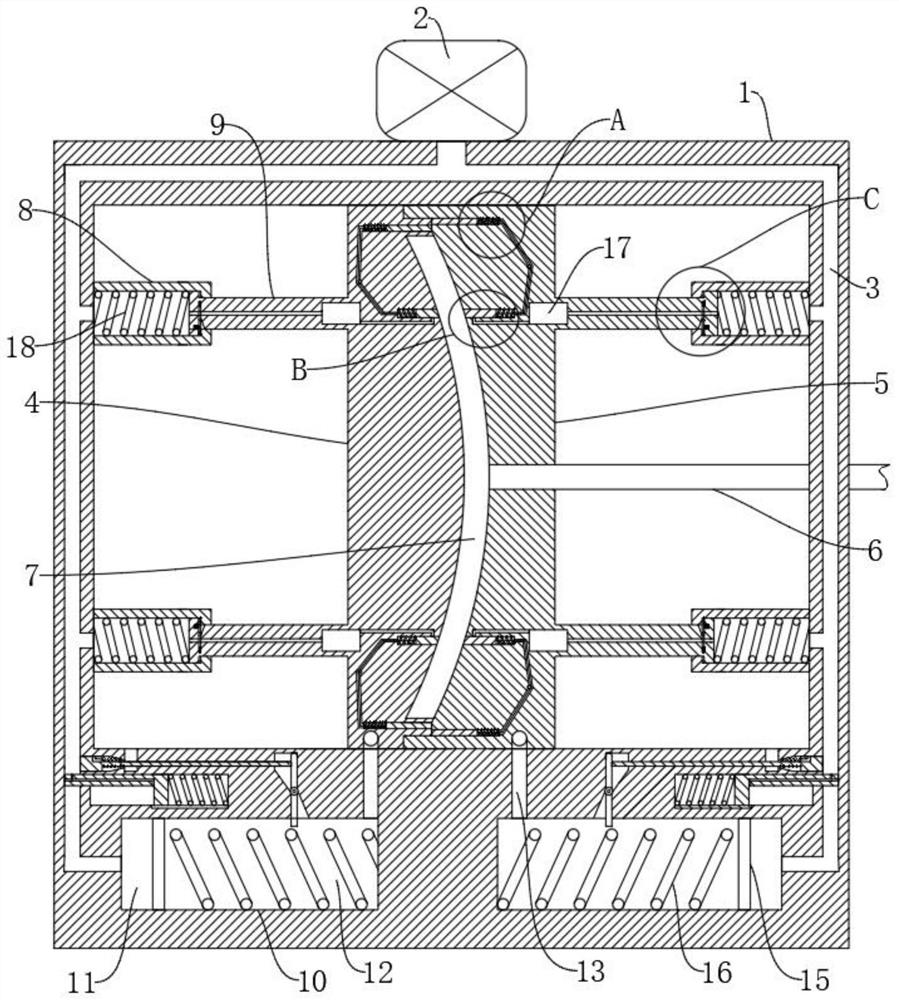

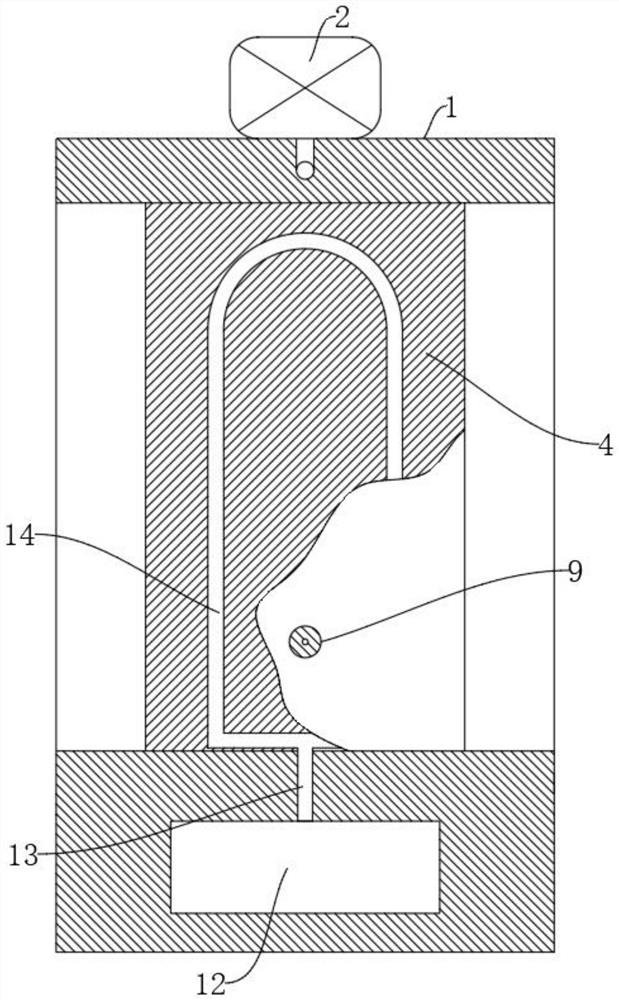

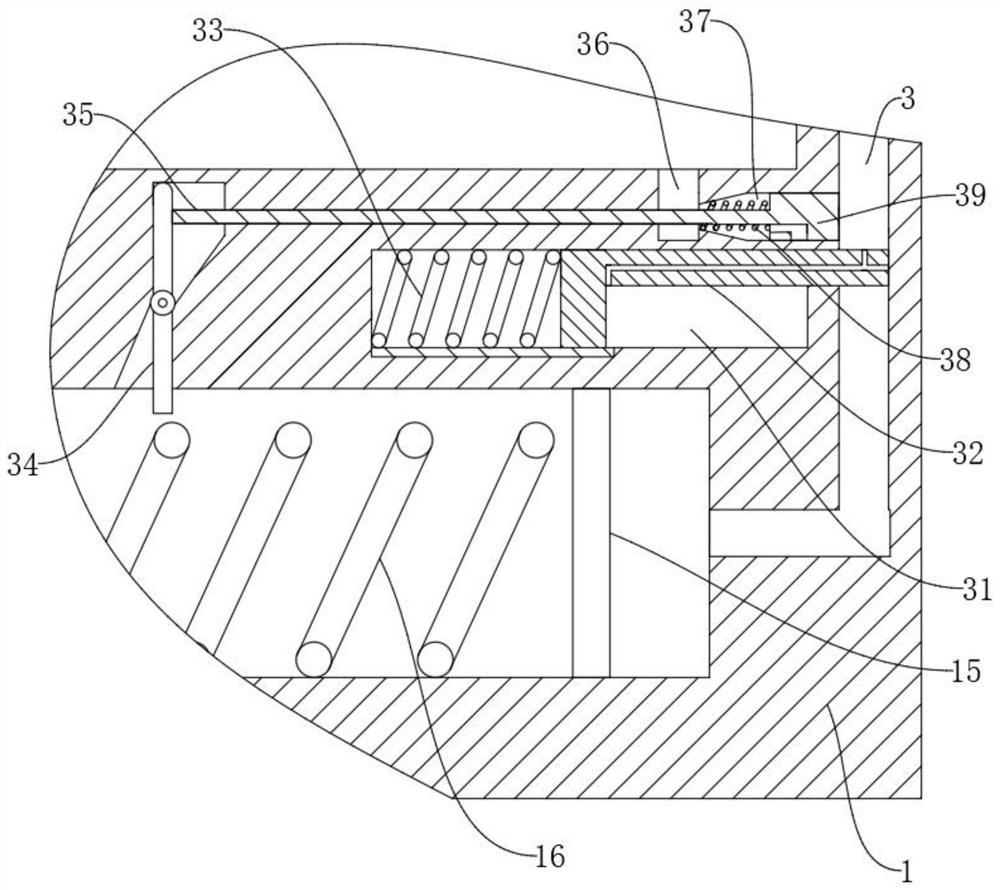

[0041] refer to Figure 1-8 , a water pump casing shaping device, comprising a working bracket 1, a first mold 4 and a second mold 5 are slidably connected in the working bracket 1, and a plurality of sets of fixed cylinders 8 are symmetrically fixedly connected to both sides of the working bracket 1, and the first The side of the mold 4 and the second mold 5 close to the fixed cylinder 8 are all symmetrically fixedly connected with a telescopic rod 9, and the telescopic rod 9 is slidingly connected with the fixed cylinder 8, and the fixed cylinder 8 is connected with a second spring 18, and the two ends of the second spring 18 They are respectively fixedly connected with the fixed cylinder 8 and the telescopic rod 9, the telescopic rod 9 is connected with an exhaust part, the upper end of the working support 1 is connected with the driving air pump 2, the output end of the driving air pump 2 is connected with the main air pipe 3, and the main air pipe 3 is connected with the f...

Embodiment 2

[0047] refer to figure 1 , Image 6 , Figure 7 , a water pump casing shaping device and its operating method, which are basically the same as in Embodiment 1, furthermore: the exhaust component includes a first air pipe 19, and the first air pipe 19 is connected in the telescopic rod 9, and the first air pipe 19 Connected with the fixed cylinder 8, the end of the telescopic rod 9 close to the fixed cylinder 8 is slidably connected with a sliding plate 20, and one end of the sliding plate 20 is rotatably connected with a first rotating rod 22, which is convenient for controlling the punching and closing of the first air pipe 19.

Embodiment 3

[0049] refer to Figure 7 , a water pump casing shaping device and its operating method, which are basically the same as in Embodiment 1, furthermore: the end of the sliding plate 20 away from the first rotating rod 22 is fixedly connected with a first return spring 21, and the first return spring 21 is fixedly connected with the telescopic rod 9 at one end away from the sliding plate 20, and is fixedly connected with a second return spring 23 on the first rotating rod 22, and is fixedly connected with the telescopic rod 9 at the end of the second returning spring 23 away from the first rotating rod 22, and slides The plate 20 is provided with a connecting hole matched with the first air pipe 19, so as to make the first rotating rod 22 and the sliding plate 20 return to their original positions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com