Automatic packaging system

A technology of automatic packaging and swinging rod, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of packaging carton damage, high cost, complex structure, etc., to achieve low carton damage rate, low cost, guaranteed open rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

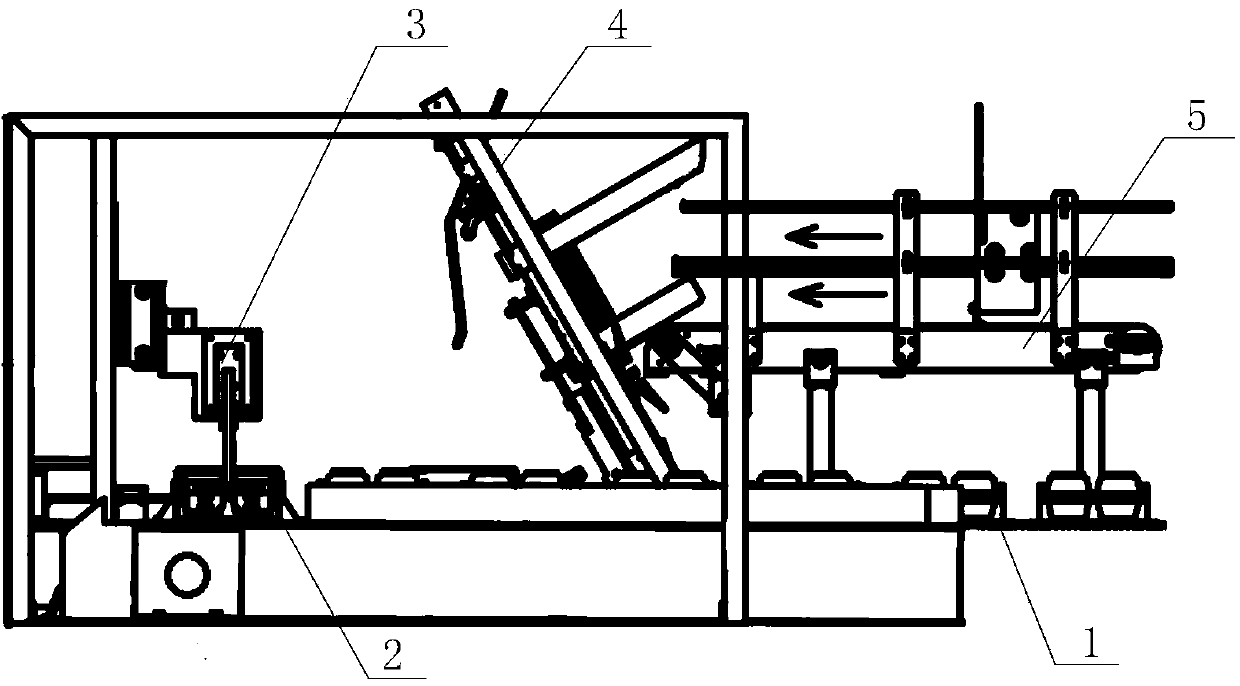

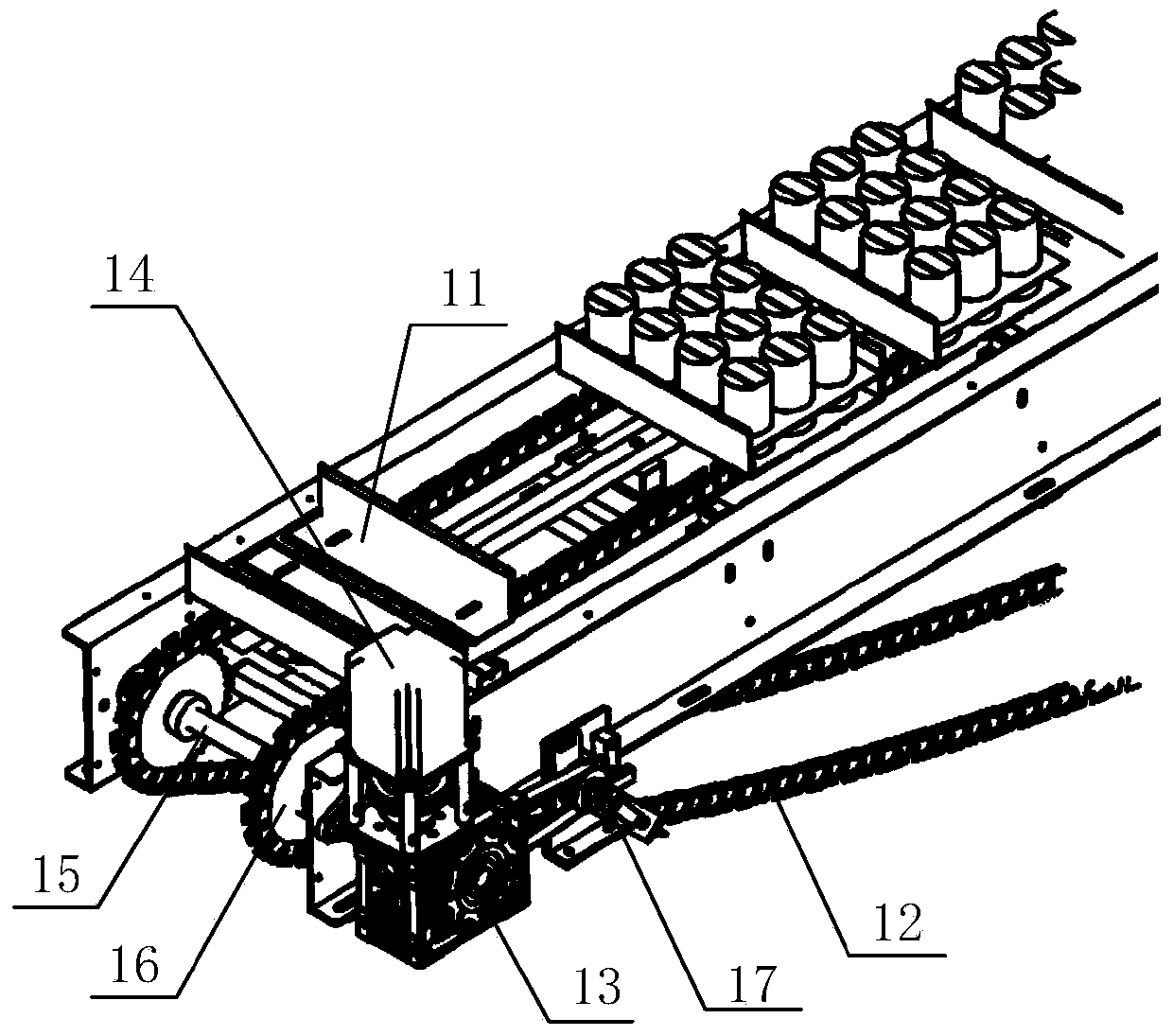

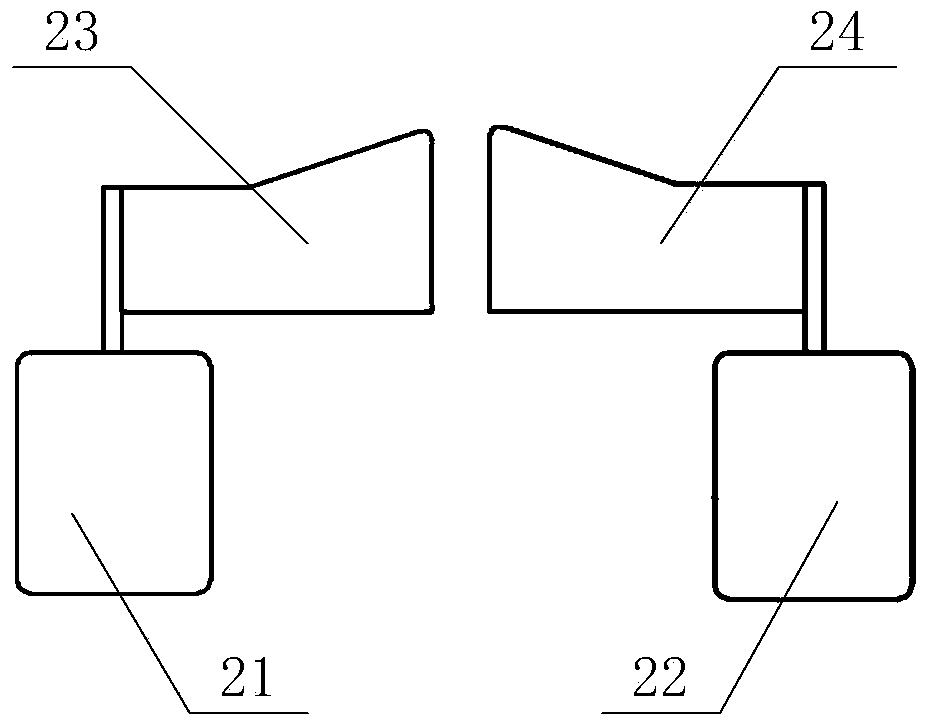

[0031] Such as Figure 1-8 As shown, the automatic packaging system of the present invention includes a product conveying device 1, a side page expanding device 2, a product pushing device 3, a folding carton opening device 4, a product position detection sensor, a carton position detection sensor and a controller. Wherein, the product delivery device 1 comprises a product conveying trough 11, a conveying chain 12, a rotating shaft 15, a gear plate 16, a drive motor 14 and a cam stepper 13, the product conveying trough 11 is installed on the conveying chain 12, and the conveying chain 12 and the gear plate 16 are meshed, the gear plate 16 is installed on the rotating shaft 15, the driving motor 14 drives the cam stepper 13 to rotate, and the cam stepper 13 drives the rotating shaft 15 to rotate; the side page spreading device 2 includes a left rotary cylinder 21 and a right rotary cylinder 22 , the left folding plate 23 and the right folding plate 24, the left folding plate 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com