Material pick-and-place device

A technology for picking and placing devices and materials, which is applied to manual conveying devices, conveyor objects, transportation and packaging, etc., can solve the problems of increasing production costs, inconvenient assembly and processing of small materials and devices, and difficulty in adapting to picking and placing operations. The effect of labor cost, simple forming method and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

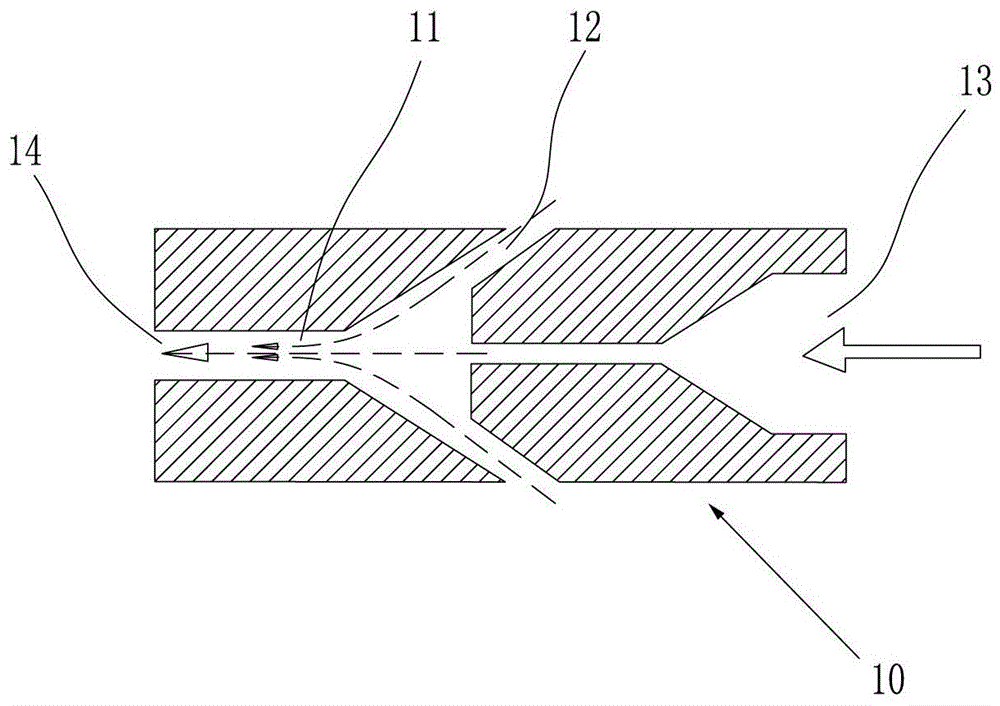

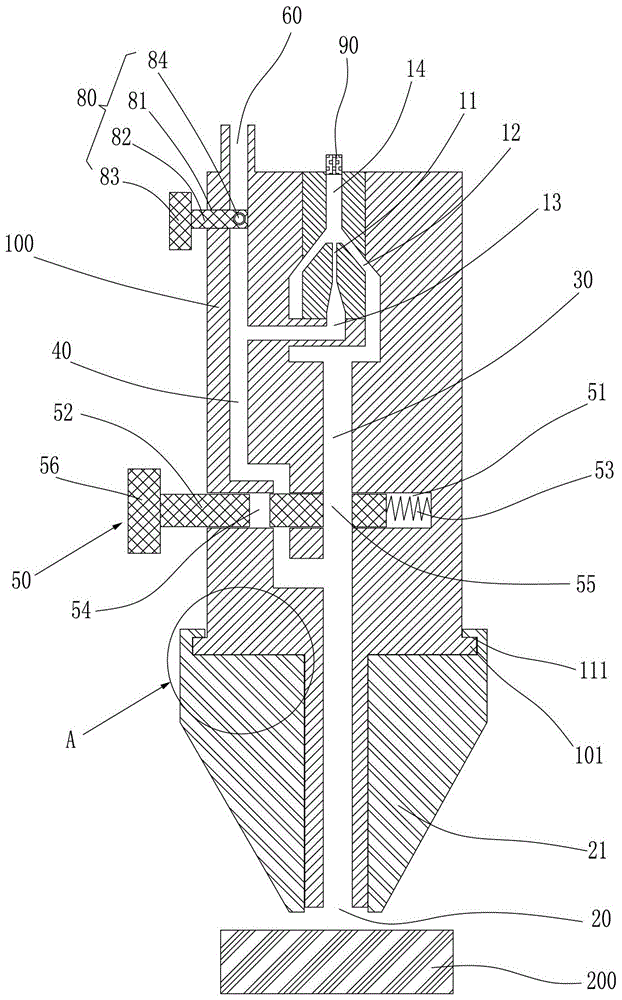

[0025] Similarly, the two inner sides of the high-pressure airway inlet 13 in the embodiment of the present invention are also set as slopes inclined towards the direction of the high-pressure airway air outlet 14, that is, on the side of the high-pressure airway inlet 13. The inner side is provided with a tapered air guide channel whose inner diameter gradually decreases from the high-pressure air channel inlet 13 to the high-pressure air channel outlet 14, so as to collect and guide the high-pressure air flow flowing into the high-pressure air channel 11. flow. As an implementation, the high-pressure airway inlet 13 may also only have one inner side thereof as an inclined surface facing the direction of the high-pressure airway outlet 14 .

[0026] In the embodiment of the present invention, the number and size of the negative pressure channels 12 can be set according to the requirements of different negative pressure values of the negative pressure airflow generated by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com