A cardboard conveying mechanism and conveying method

A conveying mechanism and cardboard technology, which is applied in transportation and packaging, object supply, pile separation, etc., can solve the problems of reducing the degree of automation of automatic production lines, a large number of manpower materials, and low productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

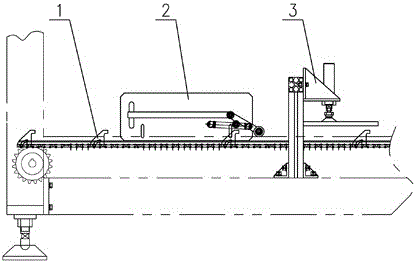

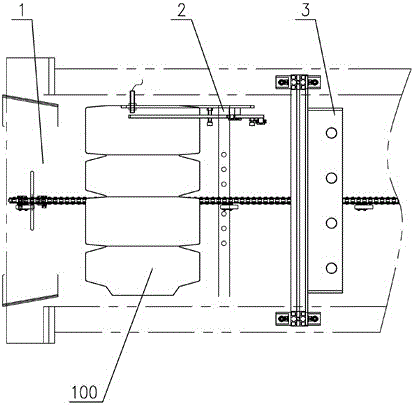

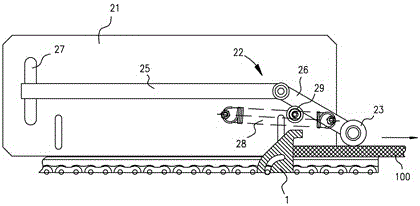

[0023] A cardboard conveying mechanism, comprising a paper feeding device 1 for feeding cardboard, a detection device 2 for detecting the number of cardboards on the paper feeding device 1, and sucking the cardboard on the paper feeding device 1 or putting the cardboard into the paper feeding device 1 The pick-and-place device 3 on the top; the detection device 2 includes a base plate 21 fixedly installed, and a detection rod 22 hinged on the base plate 21 in the middle, and a roller 23 is installed at one end of the detection rod 22, and the roller 23 is rolled against the paper feeding device 1 or the surface of the cardboard 100 on the conveying plane, the bottom plate 21 is also equipped with an inductor 24 for measuring the rotational displacement of the detection rod 22; One or more vacuum suction cups 32 that absorb the cardboard 100 on the paper feeding device. The mechanism works with the detection device and pick-and-place with the paper feeding device, which effecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com