Electromagnetic eddy current heating device for waste oil residues

An electromagnetic eddy current and heating device technology, applied in the direction of pipeline heating/cooling, pipe/pipe joint/pipe fitting, pipeline system, etc., can solve the problems of high labor intensity, inability to transfer, unsafe, etc., achieve scientific and reasonable structure and reduce labor Strength, the effect of ensuring smooth flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

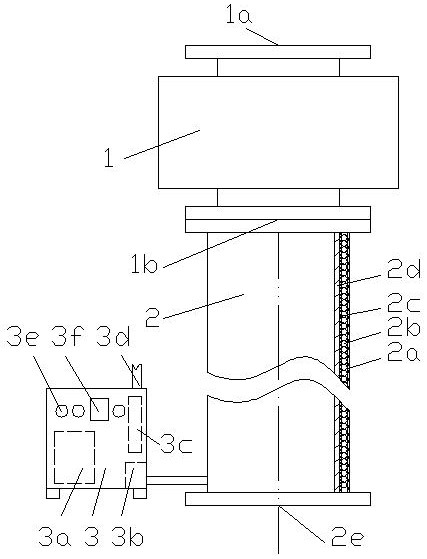

[0014] refer to figure 1 , an electromagnetic eddy current heating device for waste oil residue, the electromagnetic eddy current heating device for waste oil residue is formed by connecting a delivery pump 1, an energy regenerator 2, and an electromagnetic heating controller 3; the delivery pump 1 is provided with a delivery pump feeding port 1a, delivery pump discharge port 1b; the energy regenerator 2 is provided with an insulation layer 2c, an electromagnetic heating coil 2b, and a protective layer 2a outside the tank body wall 2d, and the tank body wall 2d is made of stainless steel, and the tank body wall One end of 2d is an oil residue inlet, and the other end is a waste oil residue outlet 2e; the electromagnetic heating controller 3 is provided with a box body, an electromagnetic generator 3a, an output end 3b, a circuit board 3c, a power input end 3d, The control switch 3e, the display panel 3f; the discharge port 1b of the delivery pump is connected to the oil residu...

Embodiment 2

[0016] refer to figure 1 , an electromagnetic eddy current heating device for waste oil residue, the electromagnetic eddy current heating device for waste oil residue is formed by connecting a delivery pump 1, an energy regenerator 2, and an electromagnetic heating controller 3; the delivery pump 1 is provided with a delivery pump feeding port 1a, delivery pump discharge port 1b; the energy regenerator 2 is provided with an insulation layer 2c, an electromagnetic heating coil 2b, and a protective layer 2a outside the tank body wall 2d, and the tank body wall 2d is made of stainless steel, and the tank body wall One end of 2d is an oil residue inlet, and the other end is a waste oil residue outlet 2e; the electromagnetic heating controller 3 is provided with a box body, an electromagnetic generator 3a, an output end 3b, a circuit board 3c, a power input end 3d, The control switch 3e, the display panel 3f; the discharge port 1b of the delivery pump is connected to the oil residu...

Embodiment 3

[0018] refer to figure 1 , an electromagnetic eddy current heating device for waste oil residue, the electromagnetic eddy current heating device for waste oil residue is formed by connecting a delivery pump 1, an energy regenerator 2, and an electromagnetic heating controller 3; the delivery pump 1 is provided with a delivery pump feeding port 1a, delivery pump discharge port 1b; the energy regenerator 2 is provided with an insulation layer 2c, an electromagnetic heating coil 2b, and a protective layer 2a outside the tank body wall 2d, and the tank body wall 2d is made of stainless steel, and the tank body wall One end of 2d is an oil residue inlet, and the other end is a waste oil residue outlet 2e; the electromagnetic heating controller 3 is provided with a box body, an electromagnetic generator 3a, an output end 3b, a circuit board 3c, a power input end 3d, The control switch 3e, the display panel 3f; the discharge port 1b of the delivery pump is connected to the oil residu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com