Centrifugal fan blade structure

A fan blade and tangent technology, applied in the field of centrifugal fan blade structure, can solve problems such as high noise, inability to characterize, and limited structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

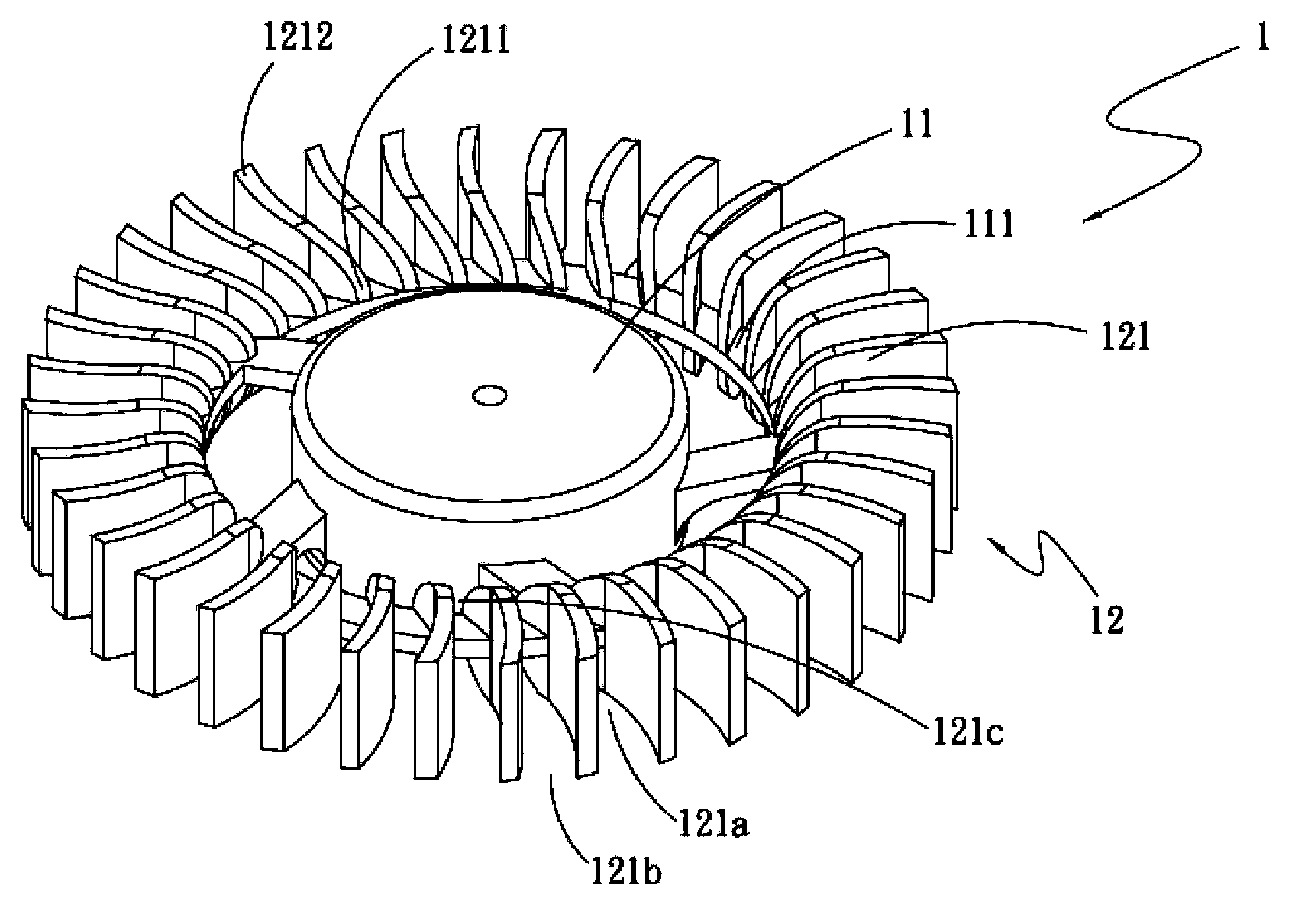

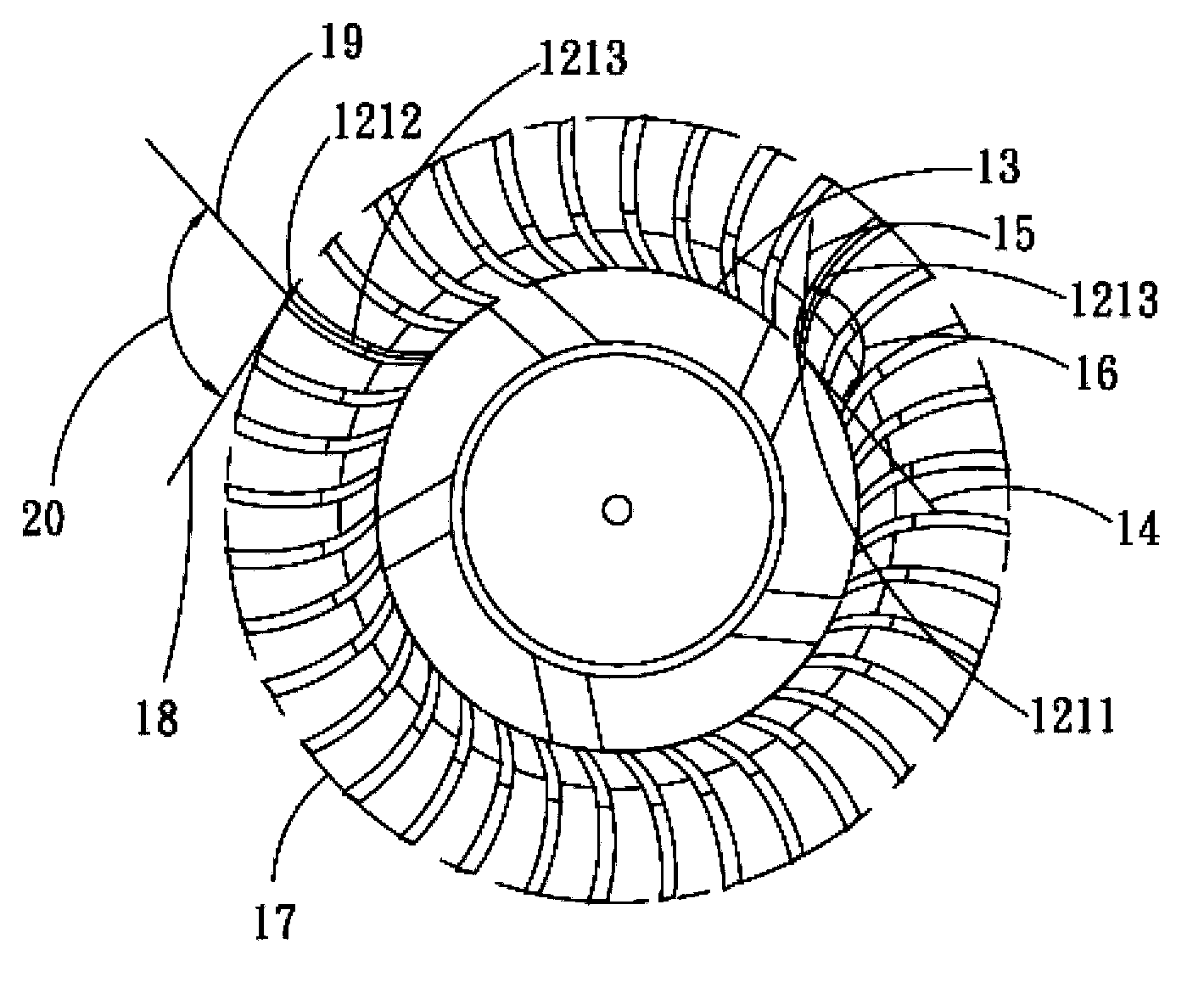

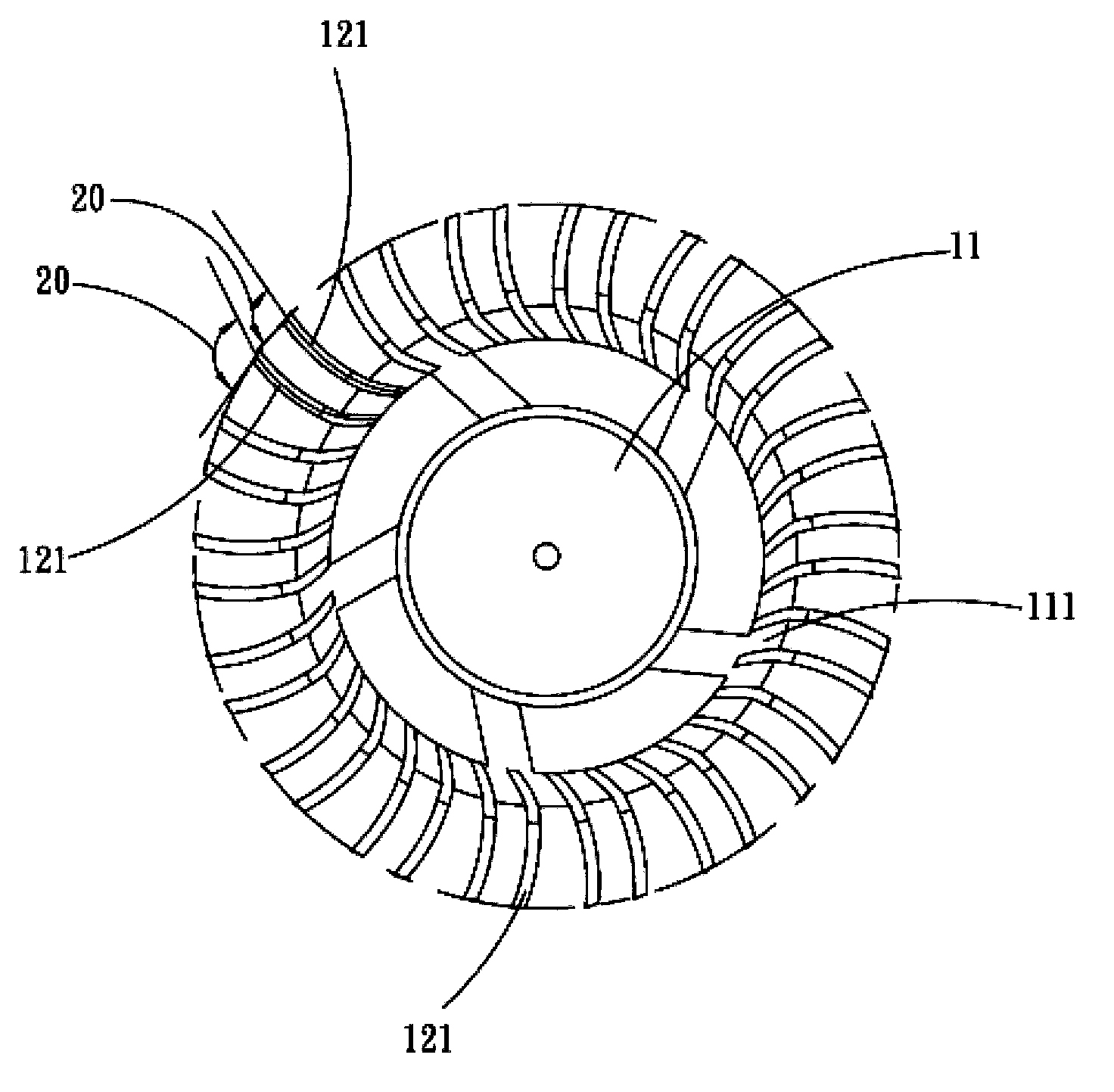

[0036] see figure 1 , figure 2 , is a three-dimensional and top view of the first embodiment of the centrifugal blade structure of the present invention, as shown in the figure, the centrifugal blade structure 1 includes: a hub 11, a blade body group 12;

[0037] The hub 11 has an extension 111;

[0038] The fan blade group 12 has a plurality of fan blade bodies 121, the fan blade body 121 is configured by extending outward from the extension portion 111, and the fan blade body 121 has a flow channel 121a and an air outlet 121b and An air inlet 121c, the air outlet 121b and the air inlet 121c are respectively arranged at two ends of the flow channel 121a and communicated with the flow channel 121a, and the air outlets 121b are not equidistantly arranged.

[0039] The blade body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com